Pore etching method of aluminum foil and method of producing etched foil

A manufacturing method and technology of corroding foil, which is applied to capacitors, circuits, electrical components, etc., can solve the problems of affecting capacitor performance, affecting capacitor shell size, increasing volume of rolls, etc., to reduce volume, improve uniformity and quantity, and ensure The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

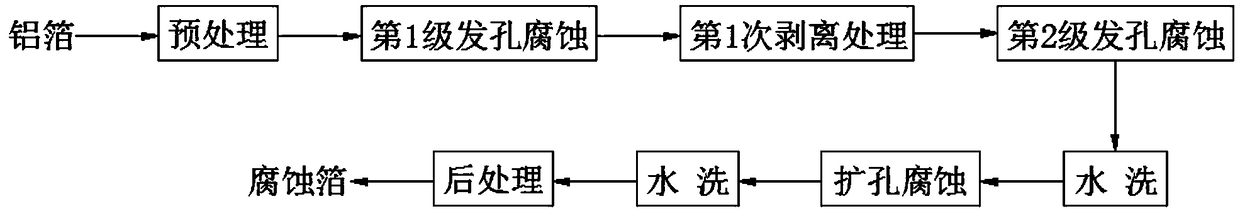

[0026] see figure 1 , which is a flow chart of the process of manufacturing the corroded foil in this embodiment, and this embodiment is specifically carried out according to the following steps:

[0027] (1) Pretreatment: Take a soft electronic aluminum foil with a purity greater than or equal to 99.99% and a thickness of 123 μm and soak it in a phosphoric acid solution with a mass fraction of 4%. The soaking temperature is 65°C and the soaking time is 60 seconds.

[0028] (2) Level 1 porosity corrosion: soak the pretreated aluminum foil in a corrosion solution containing 35% sulfuric acid and 5% hydrochloric acid by mass percentage, the soaking temperature is 75°C, and the average current density is 0.5A / cm 2 Electrolytic corrosion is carried out with a high current, and the processing time is 50 seconds.

[0029] (3) The first peeling treatment: soak the aluminum foil that has undergone the first level of porosity corrosion in a 3% fluosilicic acid solution, the soaking ...

Embodiment 2

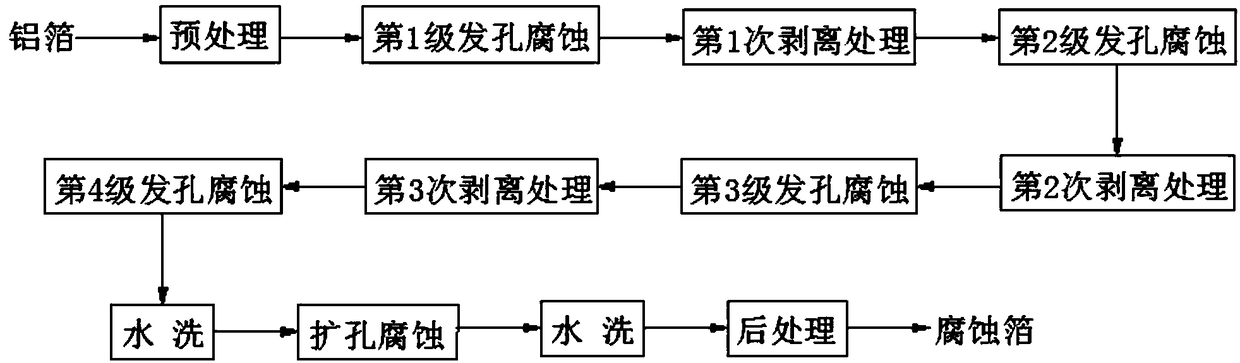

[0036] see figure 2 , which is a flow chart of the process of manufacturing the corroded foil in this embodiment, and this embodiment is specifically carried out according to the following steps:

[0037] (1) Pretreatment: Take a soft electronic aluminum foil with a purity greater than or equal to 99.99% and a thickness of 123 μm and soak it in a phosphoric acid solution with a mass fraction of 5%. The soaking temperature is 65°C and the soaking time is 60 seconds.

[0038](2) Level 1 porosity corrosion: soak the pretreated aluminum foil in a corrosion solution containing 33% sulfuric acid and 4.5% hydrochloric acid by mass percentage, the soaking temperature is 74.5°C, and the average current density is 0.53A / cm 2 Electrolytic corrosion was carried out with a high current, and the treatment time was 40 seconds.

[0039] (3) The first peeling treatment: soak the aluminum foil that has undergone the first level of porosity corrosion in a 2.5% fluorosilicic acid solution at ...

Embodiment 3

[0048] see image 3 , which is a flow chart of the process of manufacturing the corroded foil in this embodiment, and this embodiment is specifically carried out according to the following steps:

[0049] (1) Pretreatment: Take a soft electronic aluminum foil with a purity greater than or equal to 99.99% and a thickness of 123 μm and soak it in a phosphoric acid solution with a mass fraction of 2%. The soaking temperature is 75°C and the soaking time is 60 seconds.

[0050] (2) Level 1 porosity corrosion: soak the pretreated aluminum foil in a corrosion solution containing 32% sulfuric acid and 4.2% hydrochloric acid by mass percentage, the soaking temperature is 74°C, and the average current density is 0.55A / cm 2 Electrolytic corrosion is carried out with a high current, and the processing time is 30 seconds.

[0051] (3) The first peeling treatment: soak the aluminum foil that has undergone the first level of porosity corrosion in a 2% fluorosilicic acid solution, the soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com