4N tellurium preparation method based on alkaline electro-deposition process

A technology of electrodeposition and process, applied in the field of electrochemical purification and refining of scattered metal tellurium, can solve the problems of low deposition current density, high comprehensive cost, and low deposition efficiency, and achieve environmentally friendly industrialization, high deposition current density, and easy The effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

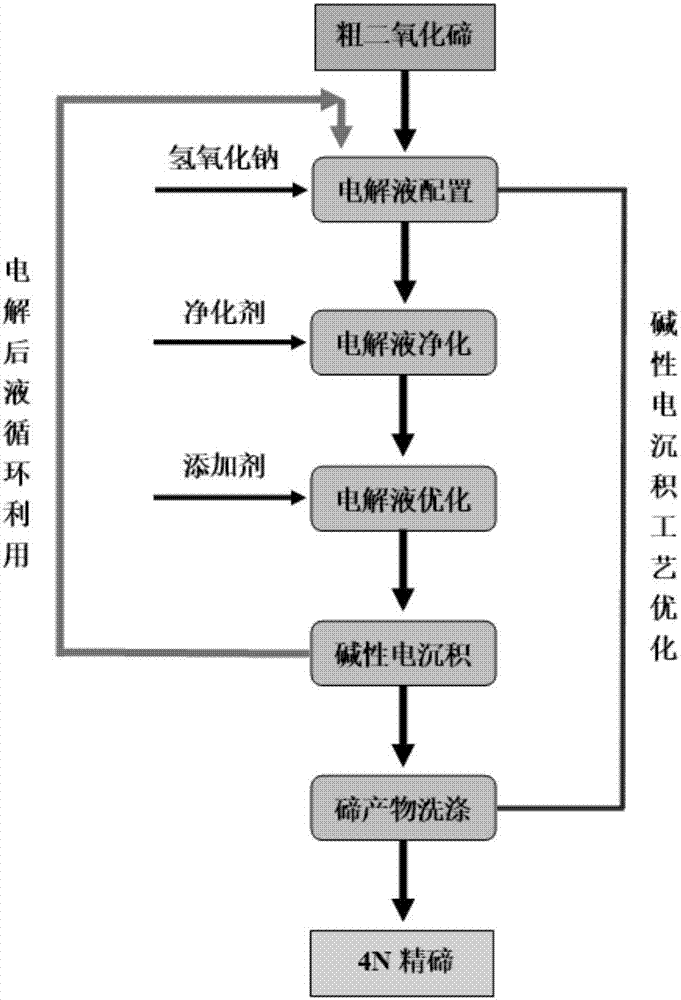

Image

Examples

preparation example Construction

[0023] The invention discloses a method for preparing 4N tellurium based on an alkaline electrodeposition process, comprising the following steps:

[0024] Step 1. Weighing: Weigh the following components in parts by weight: 1 part of sodium hydroxide tablet, 2 to 6 parts of ultrapure water, and 1 to 5 parts of coarse tellurium dioxide powder;

[0025] Step 2, at room temperature, add the weighed sodium hydroxide tablet into ultrapure water, stir and dissolve completely to obtain hot lye; add the weighed coarse tellurium dioxide powder into the hot lye for reaction, during the reaction The temperature is controlled at 70-90°C to prepare the pre-electrolyte solution; the purity of tellurium in the crude tellurium dioxide powder is ≥60%, and the water content is 15-20%;

[0026] Step 3, adding a purifier to purify the pre-electrolyte solution, controlling the temperature at 70-90°C during the treatment, and filtering to prepare an electrolyte; wherein the purifier accounts for 1...

Embodiment 1

[0035] The steps and processing conditions of the present embodiment are as follows:

[0036] Add 100g of sodium hydroxide tablets into 200g of ultrapure water, stir to dissolve completely, and obtain hot lye. Add 200g of crude tellurium dioxide (60% tellurium, 15% water) powder into the hot lye, control the temperature at 80°C during the reaction, and obtain the pre-electrolysis solution after the reaction. Add 3g of sodium sulfide to the pre-electrolysis solution for purification, control the temperature at 90°C during treatment, and filter to obtain the electrolyte solution after treatment. Cool the electrolyte to room temperature, add 0.5g of gelatin, stir and dissolve completely, and then conduct a constant voltage pre-deposition treatment on the electrolyte at 0.8V for 1h, then at 85A / m 2 Constant current electrodeposition under high current density for 30h, the electrodeposited product tellurium blocks were obtained. After stripping the tellurium block from the electrod...

Embodiment 2

[0041] Add 120g of sodium hydroxide tablets into 300g of ultrapure water, stir and dissolve completely to obtain hot lye. Add 230g of crude tellurium dioxide (60% tellurium, 15% water) powder into the hot lye, control the temperature at 90°C during the reaction, and obtain the pre-electrolysis solution after the reaction. Add 5g of ammonium thiocyanate to the pre-electrolysis solution for purification, control the temperature at 85°C during treatment, and filter to obtain the electrolyte solution after treatment. Cool the electrolyte to room temperature, add 3g of polyacrylamide, stir and dissolve completely, and conduct constant voltage pre-deposition treatment on the electrolyte at 0.75V for 8h, then at 90A / m 2 Constant current electrodeposition under high current density for 25h, the electrodeposited product tellurium blocks were obtained. After stripping the tellurium block from the electrode plate, wash it several times with ultrapure water, then dry it, and take a sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com