Light flame-retardant and sound-proof material for architectural decoration

A sound insulation material and lightweight technology, applied in the field of decoration materials, can solve the problems of poor flame retardancy, poor sound insulation effect, environmental pollution, etc., achieve excellent sound insulation performance, enhance flame retardancy and sound insulation performance, and improve blending compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

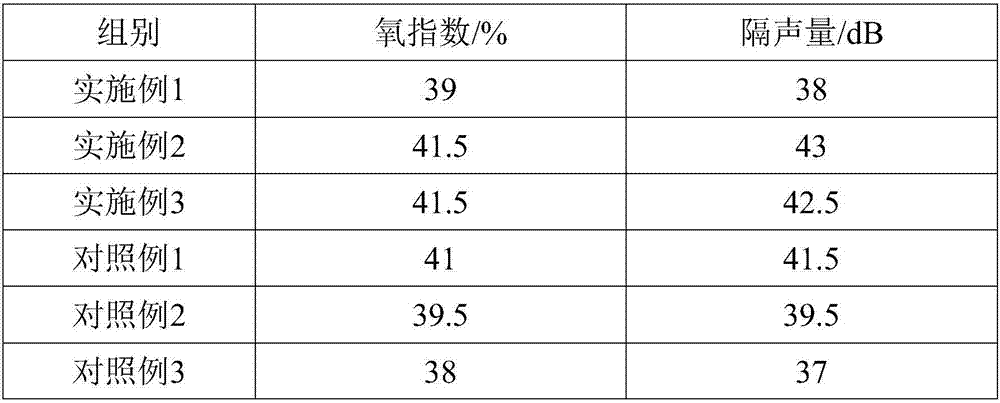

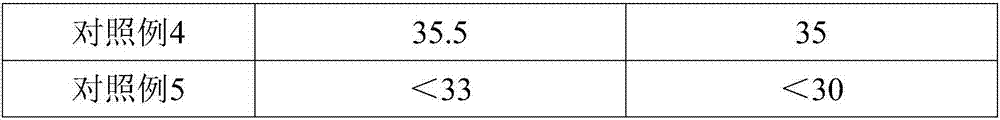

Examples

Embodiment 1

[0026] (1) Heat 20kg of fly ash to 125-130°C and mix for 10 minutes, then add 1kg of trimethylolpropane triacrylate and 0.5kg of hexamethylolmelamine hexamethyl ether, and continue to mix at 125-130°C for 30 minutes. Stand still for 15 minutes, heat again to 125-130°C and mix for 15 minutes. After natural cooling to room temperature, use a pulverizer to make 120-140 mesh powder to obtain modified fly ash;

[0027] (2) Add 5kg of sepiolite fiber and 3kg of ceramic micropowder to 10kg of chlorinated polyethylene, mix thoroughly and transfer to -15°C environment to seal and stand for 5h, then add modified fly ash, 15kg of agricultural filling waste, 5kg of Asbestos wool and 3kg of bisphenol-A epoxy resin / polyaspartic acid are heated to 125-130°C for 30 minutes and ground for 30 minutes to obtain auxiliary materials;

[0028] (3) 85 kg of polyphenylene sulfide particles, 40 kg of polycarbonate particles and the above-mentioned auxiliary materials are fully mixed and then sent into...

Embodiment 2

[0032] (1) Heat 15kg of fly ash to 125-130°C and mix for 10 minutes, then add 0.5kg of trimethylolpropane triacrylate and 1kg of hexamethylolmelamine hexamethyl ether, and continue to mix at 125-130°C for 15 minutes. Stand still for 10 minutes, heat again to 125-130°C and mix for 30 minutes. After natural cooling to room temperature, use a pulverizer to make 120-140 mesh powder to obtain modified fly ash;

[0033] (2) Add 5kg of sepiolite fiber and 2kg of ceramic micropowder to 5kg of chlorinated polyethylene, mix well and transfer to -15°C environment to seal and stand for 5h, then add modified fly ash, 10kg of agricultural filling waste, 10kg of Asbestos wool and 2kg of bisphenol-A epoxy resin / polyaspartic acid are heated to 125-130°C for 30 minutes and ground for 30 minutes to obtain auxiliary materials;

[0034] (3) 80 kg of polyphenylene sulfide particles, 35 kg of polycarbonate particles and the above-mentioned auxiliary materials are fully mixed and sent into an injecti...

Embodiment 3

[0039] (1) Heat 20kg of fly ash to 125-130°C and mix for 10 minutes, then add 1kg of trimethylolpropane triacrylate and 0.5kg of hexamethylolmelamine hexamethyl ether, and continue to mix at 125-130°C for 30 minutes. Stand still for 15 minutes, heat again to 125-130°C and mix for 15 minutes. After natural cooling to room temperature, use a pulverizer to make 120-140 mesh powder to obtain modified fly ash;

[0040] (2) Add 5kg of sepiolite fiber and 3kg of ceramic micropowder to 10kg of chlorinated polyethylene, mix thoroughly and transfer to -15°C environment to seal and stand for 5h, then add modified fly ash, 15kg of agricultural filling waste, 5kg of Asbestos wool and 3kg of bisphenol-A epoxy resin / polyaspartic acid are heated to 125-130°C for 30 minutes and ground for 30 minutes to obtain auxiliary materials;

[0041] (3) 85 kg of polyphenylene sulfide particles, 40 kg of polycarbonate particles and the above-mentioned auxiliary materials are fully mixed and then sent into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com