Road traffic stone processed and prepared from solid wastes of blast furnace slag and pulverized fuel ash

A technology of solid waste and blast furnace slag, applied in the field of curb stone, can solve the problems of curb stone material extraction, construction difficulties, pedestrian and vehicle safety hazards, and not being widely used, so as to improve mechanical performance, avoid pollution, and ensure uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

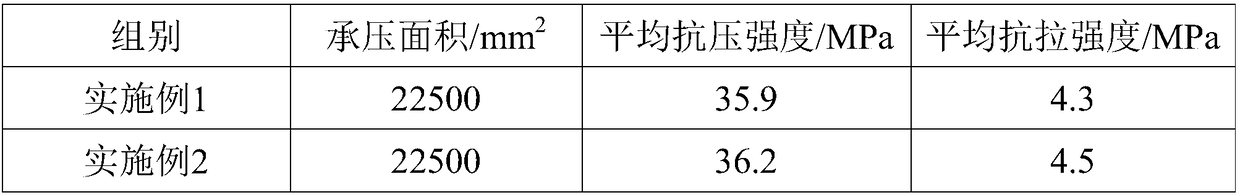

Examples

Embodiment 1

[0029] (1) The gelling property of solid waste: mix 45kg of blast furnace slag and 25kg of fly ash and soak in water, add 5kg of gelling agent after 12 hours, stir evenly, continue to soak for 24 hours, press filter, and the obtained filter residue is at 70-80 ℃ oven to dry to constant weight, and use the crushing mechanism to powder to obtain gelatinous solid waste;

[0030] (2) Preparation of the main ingredient: the gelatinous solid waste and 20kg of fine sand are mixed evenly to obtain the main ingredient;

[0031] (3) Preparation of auxiliary materials: 15kg of Portland cement, 10kg of ceramic waste micropowder and 3kg of asbestos wool are mixed uniformly to obtain auxiliary materials;

[0032] (4) Preparation of additives: Mix 2kg of petroleum coke micropowder, 1kg of polyaluminum sulfate and 0.5kg of polyborosiloxane (viscosity 2000-3000mpa.s) evenly, heat to 70-80°C and keep stirring for 15min to obtain Auxiliary;

[0033] (5) Calculus processing: mix the main materi...

Embodiment 2

[0036] (1) The gelling property of solid waste: mix 50kg of blast furnace slag and 30kg of fly ash and soak in water, add 5kg of gelling agent after 12 hours, stir evenly, continue to soak for 24 hours, press filter, and the obtained filter residue is at 70-80 ℃ oven to dry to constant weight, and use the crushing mechanism to powder to obtain gelatinous solid waste;

[0037] (2) Preparation of the main ingredient: the gelatinous solid waste and 25kg of fine sand are mixed evenly to obtain the main ingredient;

[0038] (3) Preparation of auxiliary materials: 15kg Portland cement, 10kg ceramic waste micropowder and 5kg asbestos wool are mixed evenly to obtain auxiliary materials;

[0039] (4) Preparation of additives: Mix 2kg of petroleum coke micropowder, 1kg of polyaluminum sulfate and 1kg of polyborosiloxane (viscosity 2000-3000mpa.s) evenly, heat to 70-80°C and keep stirring for 15min to obtain the assistant agent;

[0040] (5) Calculus processing: mix the main materials,...

Embodiment 3

[0043] (1) The gelling property of solid waste: mix 50kg of blast furnace slag and 30kg of fly ash and soak in water, add 5kg of gelling agent after 12 hours, stir evenly, continue to soak for 24 hours, press filter, and the obtained filter residue is at 70-80 ℃ oven to dry to constant weight, and use the crushing mechanism to powder to obtain gelatinous solid waste;

[0044] (2) Preparation of the main ingredient: the gelatinous solid waste and 25kg of fine sand are mixed evenly to obtain the main ingredient;

[0045] (3) Preparation of auxiliary materials: 15kg Portland cement, 10kg ceramic waste micropowder and 5kg asbestos wool are mixed evenly to obtain auxiliary materials;

[0046](4) Preparation of additives: Mix 2kg of petroleum coke micropowder, 1kg of polyaluminum sulfate, 1kg of polyborosiloxane (viscosity 2000-3000mpa.s) and 0.05kg of composite rare earth oxide, and heat to 70-80°C Insulated and stirred for 15 minutes to obtain the auxiliary agent;

[0047] (5) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com