Grape culture soil

A technology for cultivating soil and grapes, applied in the field of grape culturing soil, can solve problems such as low content of proanthocyanidins in grapes, and achieve the effects of improving taste and yield, increasing utilization rate and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the optional scheme of this embodiment, the preparation method of modified coal slag includes the following steps: put the coal slag into a heating furnace for full combustion, the heating temperature is 900-1200°C, then take it out and cool it to room temperature; Drying treatment, the drying temperature is 160-180°C; then put it into a pulverizer for crushing, the size is 10-20 mesh, put the crushed cinder into a circulating fluidized bed for combustion and desulfurization process, and cool after the end to normal temperature; then put the cooled cinder into the reaction kettle, add sodium sulfite solution, stir evenly for 20-30 minutes, and then dry; then put in hydrochloric acid solution for pickling, until the pH test is neutral, and then dry That is, the modified coal slag is obtained.

[0030] In the alternative of this embodiment, the desulfurization process uses dolomite as the desulfurizer, and the desulfurization process also needs to add Fe 2 o 3 , NaCl...

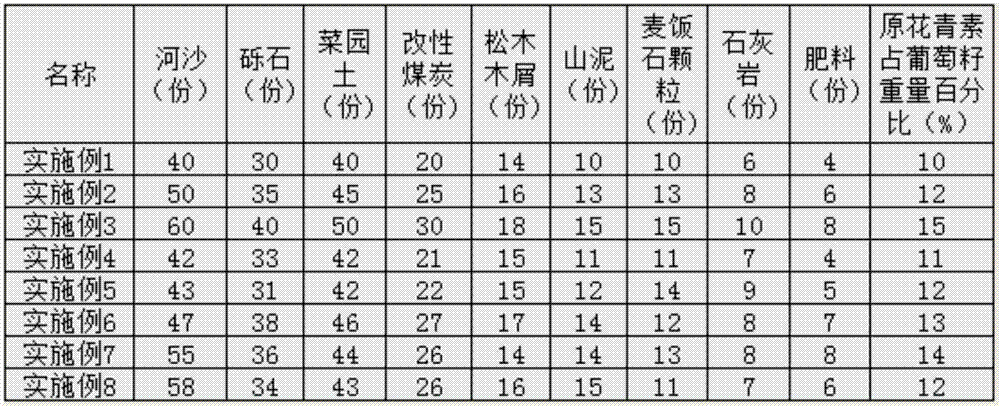

Embodiment 1

[0037] Weigh 40 parts of river sand, 30 parts of gravel, 40 parts of vegetable garden soil, 20 parts of modified cinder, 14 parts of pine sawdust, 10 parts of mountain mud, 10 parts of medical stone particles, 6 parts of limestone, and 4 parts of fertilizer ;

[0038] After weighing,

[0039] Crush the gravel, sieve it through a 50-80 mesh, and set aside;

[0040] Put the coal slag into the heating furnace for full combustion, the heating temperature is 900-1200°C, then take it out and cool it to room temperature; then wash it with water, and then dry it at a temperature of 160-180°C; then put it into a pulverizer for crushing, The size is 10-20 mesh, put the pulverized coal cinder into the circulating fluidized bed, carry out the combustion and desulfurization process, and cool to normal temperature after the end; then put the cooled coal cinder into the reaction kettle, add the concentration of 16% Sodium sulfite solution, uniformly stirred for 20-30 minutes, and then drie...

Embodiment 2

[0046] Weigh 50 parts of river sand, 35 parts of gravel, 45 parts of vegetable garden soil, 25 parts of modified cinder, 16 parts of pine sawdust, 13 parts of mountain mud, 13 parts of medical stone particles, 8 parts of limestone, and 6 parts of fertilizer ;

[0047] After weighing,

[0048] Crush the gravel, sieve it through a 50-80 mesh, and set aside;

[0049] Put the coal slag into the heating furnace for full combustion, the heating temperature is 900-1200°C, then take it out and cool it to room temperature; then wash it with water, and then dry it at a temperature of 160-180°C; then put it into a pulverizer for crushing, The size is 10-20 mesh, put the pulverized coal cinder into the circulating fluidized bed, carry out the combustion and desulfurization process, and cool to normal temperature after the end; then put the cooled coal cinder into the reaction kettle, add the concentration of 16% Sodium sulfite solution, uniformly stirred for 20-30 minutes, and then drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com