A kind of composite thermal spraying method

A technology of thermal spraying and powder spraying, applied in the direction of coating, molten spraying, metal material coating process, etc., can solve the problems of difficult to spray and easily oxidized materials, difficult to spray and easy to oxidize, fiber or whisker addition, etc. Achieve the effects of shortening the time of heating or oxidation, low heating temperature, and preventing melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The wear-resistant coating was prepared by spraying diamond powder with composite thermal spraying technology based on atmospheric plasma spraying.

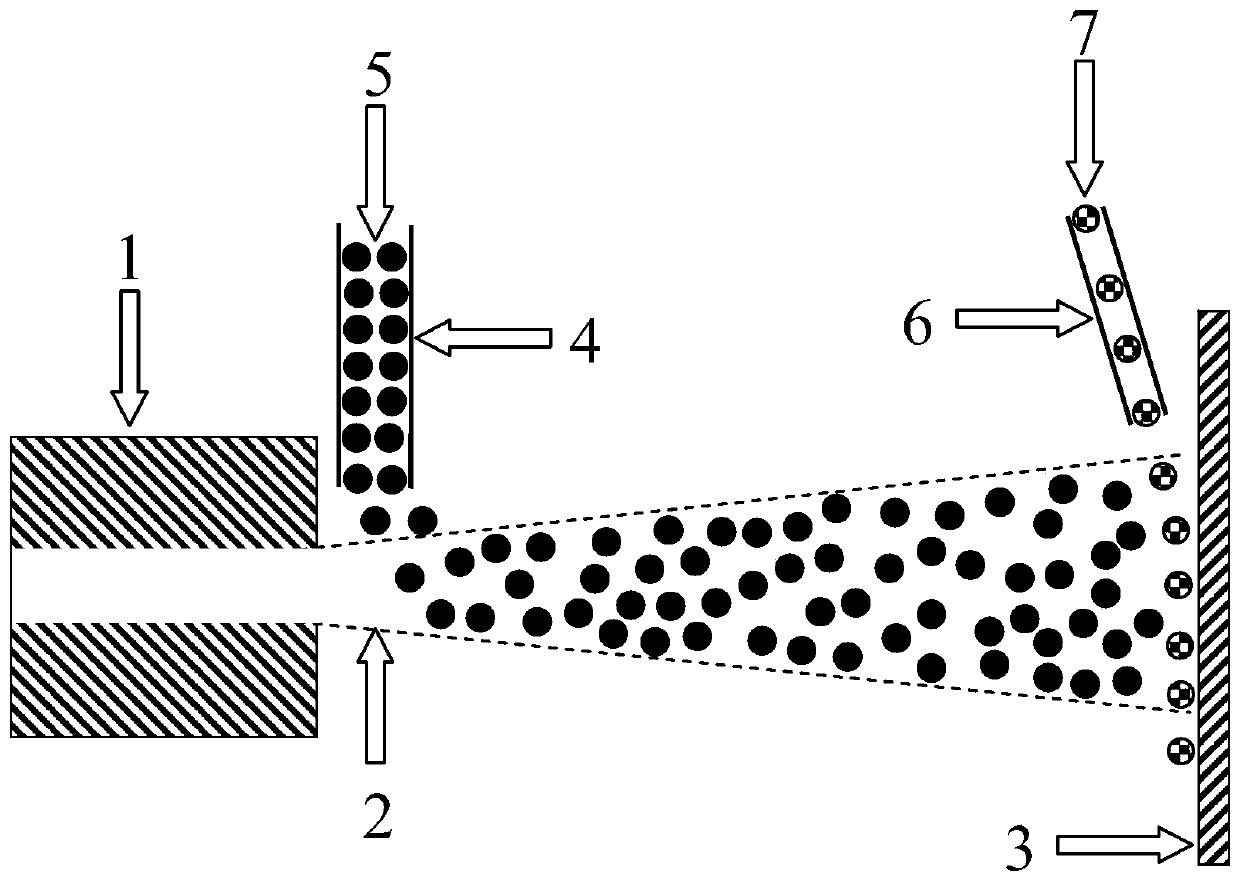

[0028] First, add a powder feeding tube to the spray gun, such as figure 1 As shown, the powder feeding pipe adopts an alumina ceramic tube with an inner diameter of 2.5 mm, and the length is about 15 cm. The powder feeding port is about 2 cm above the flame, and the included angle with the flame is about 70°. The powder feed port is connected to the top of the diamond powder feeder.

[0029] Next, the stainless steel substrate is cleaned and sandblasted. Atmospheric plasma spraying is then performed. The spraying current is 380A, the voltage is 150V, the flow rate of the main gas argon is 90L / min, the flow rate of hydrogen is 15L / min, and the distance between the spray gun and the substrate is 100mm. Metal powder is fed into the original powder feeding port; diamond powder is fed into the newly added powder feeding por...

Embodiment 2

[0031] The composite thermal spraying technology based on atmospheric plasma spraying was used to spray the zirconia whisker toughened thermal barrier coating.

[0032] First, add a powder feeding tube to the spray gun, such as figure 1 As shown, the powder feeding pipe adopts an alumina ceramic tube with an inner diameter of 2.5 mm, and the length is about 15 cm. The powder feeding port is about 2 cm above the flame, and the included angle with the flame is about 70°. The powder feed port is connected to the zirconia whisker powder feeder.

[0033] Secondly, the superalloy substrate is cleaned and sandblasted. The metal bond coat was then prepared using atmospheric plasma spraying. The spraying current is 380A, the voltage is 150V, the flow rate of the main gas argon is 90L / min, the flow rate of hydrogen is 15L / min, and the distance between the spray gun and the substrate is 100mm. The powder feeding amount of the metal powder NiCoCrAlY is 20g / min, and the flow rate of the...

Embodiment 3

[0036] The composite thermal spraying technology based on atmospheric plasma spraying is used to spray graphite powder to adjust the porosity of thermal barrier coating.

[0037] First, add a powder feeding tube to the spray gun, such as figure 1 As shown, the powder feeding pipe adopts an alumina ceramic tube with an inner diameter of 2.5 mm, and the length is about 15 cm. The powder feeding port is about 2 cm above the flame, and the included angle with the flame is about 70°. The powder feeding port is connected to the graphite powder feeder.

[0038] Secondly, the superalloy substrate is cleaned and sandblasted. The metal bond coat was then prepared using atmospheric plasma spraying. The spraying current is 380A, the voltage is 150V, the flow rate of the main gas argon is 90L / min, the flow rate of hydrogen is 15L / min, and the distance between the spray gun and the substrate is 100mm. The powder feeding amount of the metal powder NiCoCrAlY is 20g / min, and the flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com