Nanometer lipid emulsion

A fat emulsion and nanotechnology, applied in the field of medicine, can solve problems such as drug degradation, limitation of cleaning operation methods, improper preparation, etc., and achieve the effects of being conducive to safe consumption, observation and judgment, and excellent stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

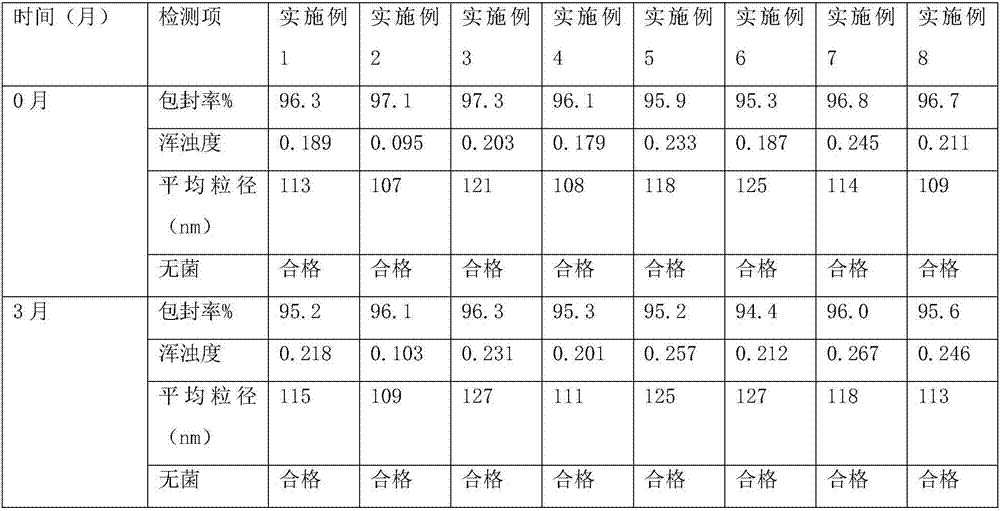

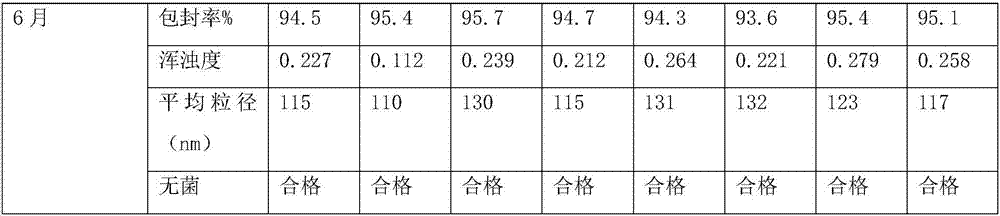

Examples

Embodiment 1

[0035] Embodiment 1: A kind of fat emulsion (injection) containing docetaxel, docetaxel 100mg, refined soybean oil 30mg, refined egg yolk lecithin 2.5g, oleic acid 310mg, propylene glycol 3.15g are fully stirred and mixed under the condition of 55 ℃ to form oily phase. Add 125mL of purified water gradually to the above oil phase, and then carry out primary emulsification at 12000rmp for 12 minutes. Then add purified water, add the volume of the liquid to 150mL, mix, and use a high-pressure homogenizer to set the emulsification pressure at 800kgf / cm 2 , and then circulate emulsification 20 times. After emulsification, add 0.1N pH regulator hydrochloric acid aqueous solution to adjust the pH to 6.0, put the nano fat emulsion into a glass ampoule, and perform high-pressure steam sterilization at 121°C for 12 minutes, that is, the fat of docetaxel emulsion.

Embodiment 2

[0036] Example 2: A fat emulsion (injection) containing docetaxel, 100 mg of docetaxel, 30 mg of refined soybean oil, 2.5 g of refined egg yolk lecithin, 310 mg of oleic acid, and 3.15 g of propylene glycol were fully stirred and mixed at 55° C. oily phase. The above oil phase was gradually added with 125 mL of purified water containing 12 g of inositol, and then the primary emulsification was carried out at a rotation speed of 12000 rpm for 12 minutes. Then add purified water, add the volume of the liquid to 150mL, mix, and use a high-pressure homogenizer to set the emulsification pressure at 800kgf / cm 2 , and then circulate emulsification 20 times. After emulsification, add 0.1N pH regulator hydrochloric acid aqueous solution to adjust the pH to 6.0, put the nano fat emulsion into a glass ampoule, and perform high-pressure steam sterilization at 121°C for 12 minutes, that is, the fat of docetaxel emulsion.

Embodiment 3

[0037] Example 3: A fat emulsion injection containing indomethacin, 80mg of indomethacin, 90mg of refined soybean oil, 2g of refined egg yolk lecithin, 250mg of oleic acid, and 3.15g of propylene glycol were fully stirred and mixed at 55°C to form an oil Mutually. Add 125mL of purified water gradually to the above oil phase, and then carry out primary emulsification at 12000rmp for 12 minutes. Then add purified water, add the volume of the liquid to 150mL, mix, and use a high-pressure homogenizer to set the emulsification pressure at 850kgf / cm 2 , and then circulate emulsification 20 times. After emulsification, add 0.1N pH regulator hydrochloric acid aqueous solution to adjust the pH to 6.0, put the nano-fat emulsion into a glass ampoule, and perform high-pressure steam sterilization at 121°C for 15 minutes to obtain indomethacin. fat emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com