a diaphragm

An integrated, arc-shaped technology, applied in the direction of non-planar diaphragm/paper cone, diaphragm structure, transducer diaphragm, etc., can solve the problem of easy adsorption of air impurities and dust, low thermal stability, and elastic diaphragm Problems such as poor resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

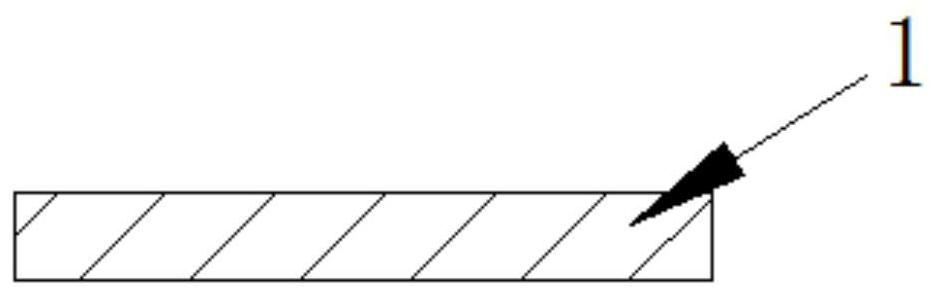

[0035] Such as figure 1 As shown, this embodiment discloses a diaphragm, which includes a single-layer thermoplastic vulcanized silica gel (hereinafter referred to as TPSiV) material layer 1, and the single-layer TPSiV material layer 1 can be doped with polymer materials, elastomer materials, silica gel One or more of the materials, among which polymer materials include PEEK (polyetheretherketone), PAR (polyarylate), PEI (polyetherimide), PEN (polyethylene naphthalate), etc. , Elastomer materials include TPE (thermoplastic elastomer), TPU (thermoplastic polyurethane elastomer), TPC (thermoplastic-based composite material), etc.; the diaphragm of TPSiV material can be thermocompressed or injection molded. Compared with silicone materials, injection molding is generally used. Molding, the manufacturing process is simpler.

[0036]As a specific application, the diaphragm can be applied to loudspeaker products. The speaker can be round, square or track-shaped, and the above-menti...

Embodiment 2

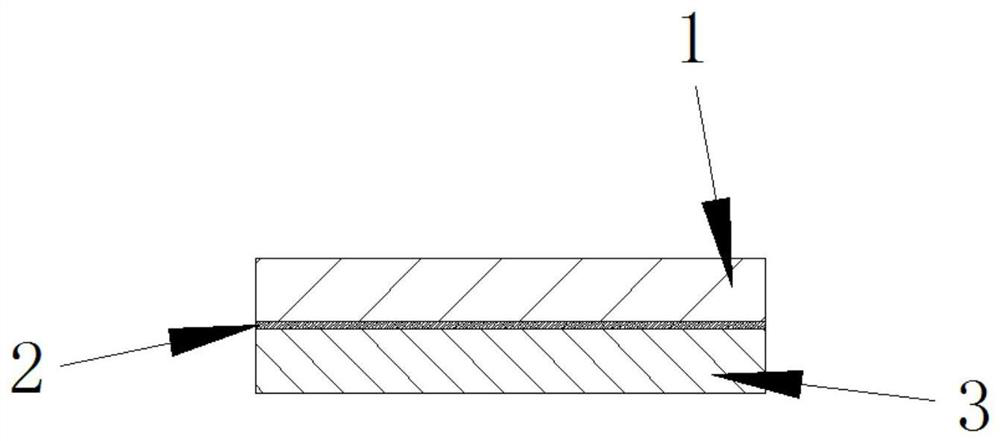

[0038] Such as figure 2 As shown, in this embodiment, the diaphragm includes a layer of TPSiV material layer 1 and a layer of PEEK material layer 3, wherein a glue layer 2 may be arranged between the TPSiV material layer and the PEEK material layer, and of course, glue may not be provided. The setting of the layer 2 and the glue layer 2 can increase the damping characteristics of the material, and the presence or absence of the glue layer 2 does not affect the protection range of the diaphragm of the present invention.

[0039] In this embodiment, the TPSiV material layer 1 and the PEEK material layer 3 are combined, and the PEEK material layer 3 is only a preferred embodiment. The PEEK material here can be replaced with a TPSiV material, or a polymer such as a PAR material or a PEI material. materials, or replaced by elastic materials such as TPU materials, TPE materials, TPC materials, or replaced by silica gel materials, do not affect the protection scope of the present in...

Embodiment 3

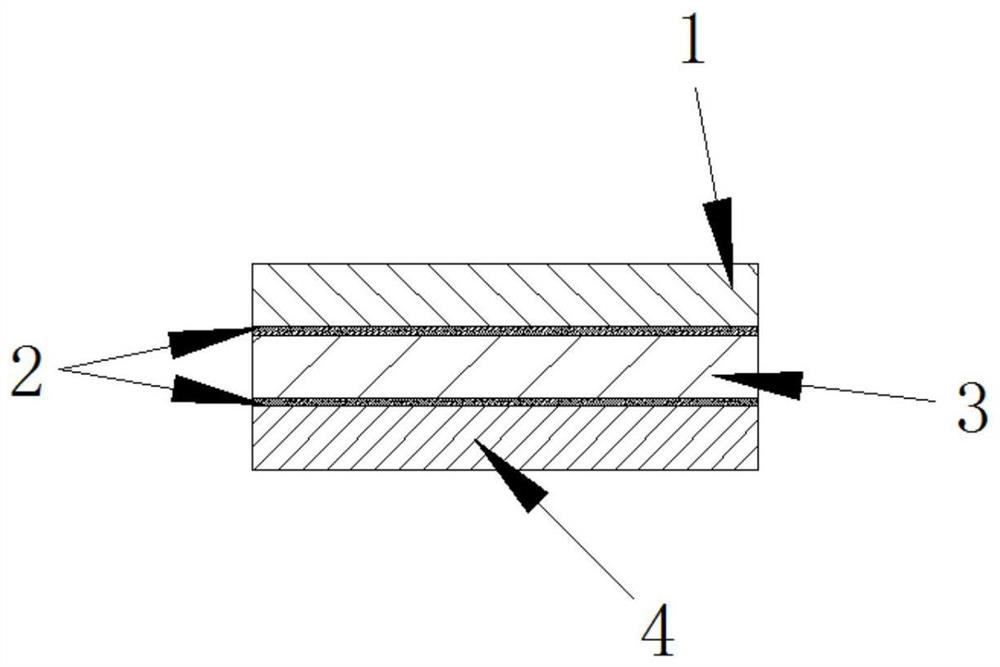

[0042] Such as image 3 As shown, the diaphragm in this embodiment is basically the same as that in Embodiment 2, except that the novel diaphragm disclosed in this embodiment is composed of TPSiV material layer 1, PEEK material layer 3 and TPU material layer 4, wherein the material The layers are bonded through the adhesive layer 2. Similarly, different material layers can also be bonded by injection molding or thermocompression. Similar to Embodiment 2, the TPSiV material layer or a multilayer material containing TPSiV can be used as an embedded material and Silicone material injection molding.

[0043] In this embodiment, the PEEK material layer 3 and the TPU material layer 4 are only a preferred implementation mode. The diaphragm composed of three layers of materials in this embodiment is not limited to the combination of these three materials, nor is it limited to the combination of TPSiV material and The composite of polymer material and elastomer material may also be th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com