Stainless steel color precoated steel plates

A color-coated steel plate and stainless steel plate technology, which is applied in coatings, metal material coating processes, and devices for coating liquid on the surface, can solve the problems of insufficient corrosion resistance of color-coated steel plates and achieve excellent machining performance, Strong mechanical processing performance, colorful and colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

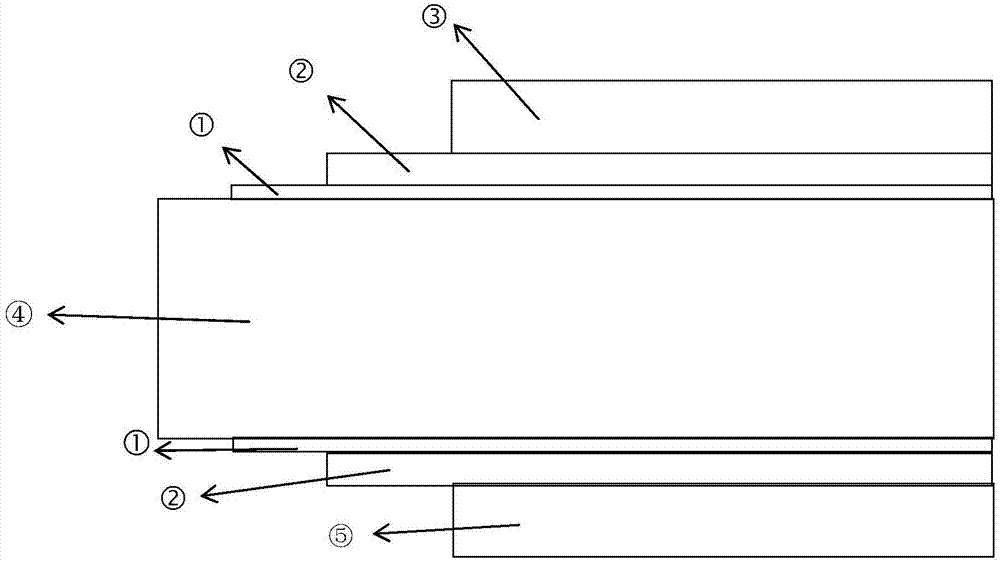

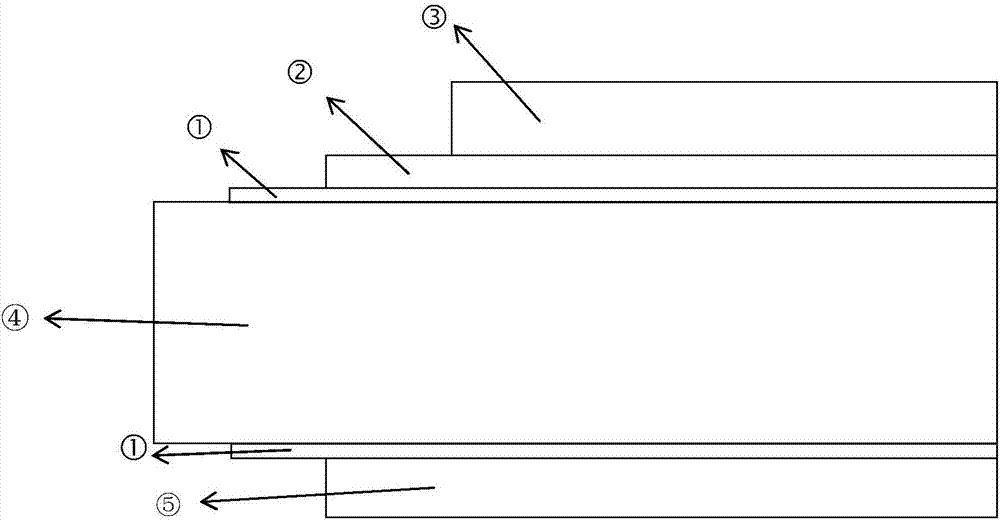

[0029] Such as figure 1 As shown, the first structure of the present invention is centered on the stainless steel substrate, and the passivation layer, the primer layer and the topcoat layer are all coated successively on the upper and lower surfaces thereof; wherein the topcoat layer on the upper surface of the stainless steel substrate is The front finish paint layer, the finish paint layer on the lower surface of the stainless steel substrate is the back finish paint layer.

[0030] Wherein, the base material is 304 type stainless steel; the raw material composition mass percent of passive film is: halide 8%; Potassium sodium tartrate 2%; Sodium nitrate 10%; Chromium nitrate 18%; Sulfuric acid 12%; Nitric acid 5%; 1.5% cobalt; 0.5% hydrochloric acid; 2% sodium alkyl sulfate; the rest is pure water.

[0031] The front primer is an epoxy primer, which has stronger adhesion and better water boiling resistance than ordinary paint. Thickness: 5 microns; the front topcoat is po...

Embodiment 2

[0035] Such as figure 1 As shown, the first structure of the present invention is centered on the stainless steel substrate, and the passivation layer, the primer layer and the topcoat layer are all coated successively on the upper and lower surfaces thereof; wherein the topcoat layer on the upper surface of the stainless steel substrate is The front finish paint layer, the finish paint layer on the lower surface of the stainless steel substrate is the back finish paint layer.

[0036] Wherein, the base material is 430 type stainless steel; the raw material composition mass percent of passive film is: halide 8%; Potassium sodium tartrate 2%; Sodium nitrate 10%; Chromium nitrate 18%; Sulfuric acid 12%; Nitric acid 5%; 1.5% cobalt; 0.5% hydrochloric acid; 2% sodium alkyl sulfate; the rest is pure water.

[0037] The front primer is an epoxy primer, which has stronger adhesion and better water boiling resistance than ordinary paint. Thickness: 5 microns; the front topcoat is po...

Embodiment 3

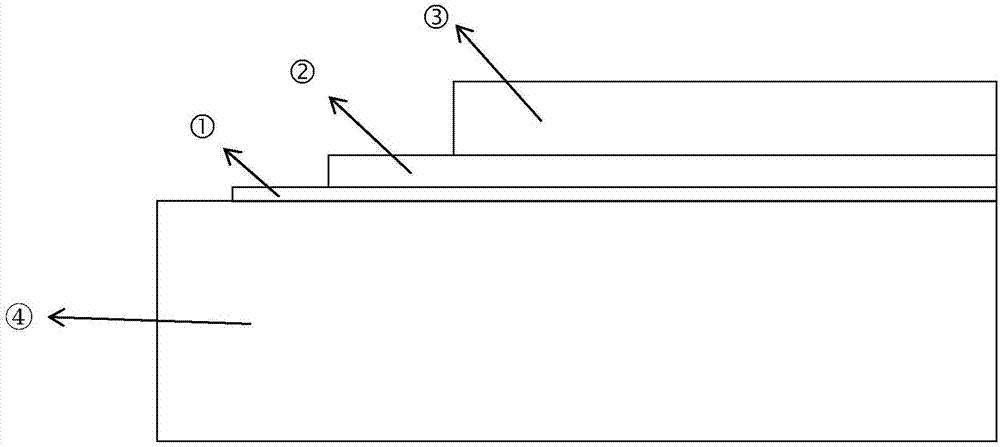

[0041] Such as figure 2 As shown, the second structure of the present invention is to sequentially coat a front passivation layer, a front primer layer and a front finish paint layer on the upper surface of the stainless steel substrate. The lower surface of the stainless steel substrate is not primed and backpainted.

[0042] Wherein, the base material is stainless steel of 201 type; The raw material composition mass percent of passivation film is: Halide 9%; Potassium sodium tartrate 4%; Sodium nitrate 15%; Chromium nitrate 12%; Sulfuric acid 8%; 1.5% cobalt; 1% hydrochloric acid; 3% sodium alkyl sulfate; the rest is pure water.

[0043] The primer is a fluorocarbon primer, which has stronger adhesion and better water boiling resistance than ordinary fluorocarbon paints. Thickness: 10 microns; the front surface paint is fluorocarbon topcoat, which has better compatibility with primer than ordinary fluorocarbon paint, high hardness and good processing performance. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com