Environmental stain-resistant emulsion paint for exterior walls

A latex paint and stain-resistant technology, applied in the field of exterior wall latex paint, can solve the problems of low volume solid content, poor water and weather resistance, weak adhesion, etc., and achieve the effect of good surface tension, low surface energy and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

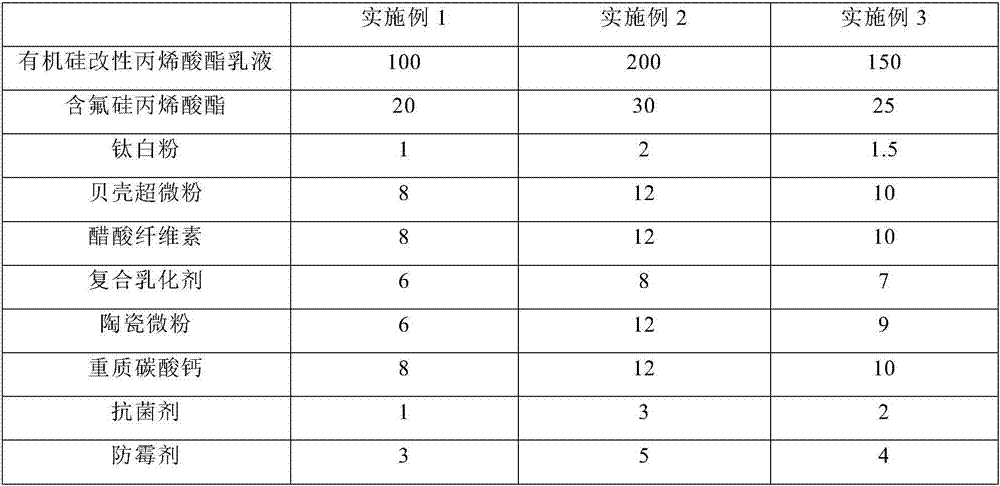

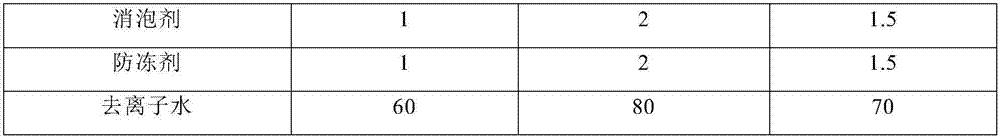

Examples

Embodiment 1

[0028] The preparation method of the silicone-modified acrylate emulsion is to add ammonium persulfate into an initiator tank equipped with deionized water, and stir evenly to obtain an initiator solution with a concentration of 2%; methyl acrylate, ethyl acrylate Ester, glycidyl methacrylate, octamethylcyclotetrasiloxane (D4) were mixed uniformly in the premixing tank to obtain a mixed phase of polymerized monomers; sodium dodecyl allyl succinate and deionized water were added Into the four-neck flask, heated to 60°C, slowly dropwise mixed homogeneous polymerized monomer mixed phase and 80% initiator solution for 1 hour, during the reaction process, the temperature was maintained at 60°C, and the rotation speed was maintained at 200r / min; After dropping and keeping warm for 1 hour, the temperature is 60°C, then add the remaining 20% initiator solution dropwise, and when the system is cooled to 40°C, add sodium bicarbonate to adjust the pH value to 6.

[0029] The titanium d...

Embodiment 2

[0038] The preparation method of the silicone-modified acrylate emulsion is to add ammonium persulfate into an initiator tank equipped with deionized water, stir evenly to obtain an initiator solution with a concentration of 3%; mix methyl acrylate, ethyl acrylate Ester, glycidyl methacrylate, octamethylcyclotetrasiloxane (D4) were mixed uniformly in the premixing tank to obtain a mixed phase of polymerized monomers; sodium dodecyl allyl succinate and deionized water were added Into a four-neck flask, heated to 80°C, slowly dropwise mixed homogeneous polymerized monomer mixed phase and 80% initiator solution for 2 hours, during the reaction process, the temperature was maintained at 80°C, and the rotation speed was maintained at 300r / min; After dropping and keeping warm for 2 hours, the temperature is 80°C, then add the remaining 20% initiator solution dropwise, and when the system is cooled to 40°C, add sodium bicarbonate to adjust the pH value to 8.

[0039] The titanium d...

Embodiment 3

[0048] The preparation method of the silicone-modified acrylate emulsion is to add ammonium persulfate into an initiator tank equipped with deionized water, stir evenly to obtain an initiator solution with a concentration of 2.5%; mix methyl acrylate, ethyl acrylate Ester, glycidyl methacrylate, octamethylcyclotetrasiloxane (D4) were mixed uniformly in the premixing tank to obtain a mixed phase of polymerized monomers; sodium dodecyl allyl succinate and deionized water were added Into the four-necked flask, heated to 70°C, slowly added dropwise the homogeneously mixed polymerized monomer mixed phase and 80% initiator solution for 1.5 hours, the temperature during the reaction was maintained at 70°C, and the rotation speed was maintained at 250r / min After dropping and keeping warm for 1.5h, the temperature is 70°C, then dropwise add the remaining 20% initiator solution, and when the system is cooled to 40°C, add sodium bicarbonate to adjust the pH value to 6-8.

[0049] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com