Preparation method of waterborne polyurethane/graphene nano-composite emulsion

A water-based polyurethane and nano-composite technology, which is applied in the field of preparation of inorganic nano-material modified polyurethane, can solve the problems that limit the wide application of water-based polyurethane, and achieve the effect of enhanced interaction force, easy control of reaction and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

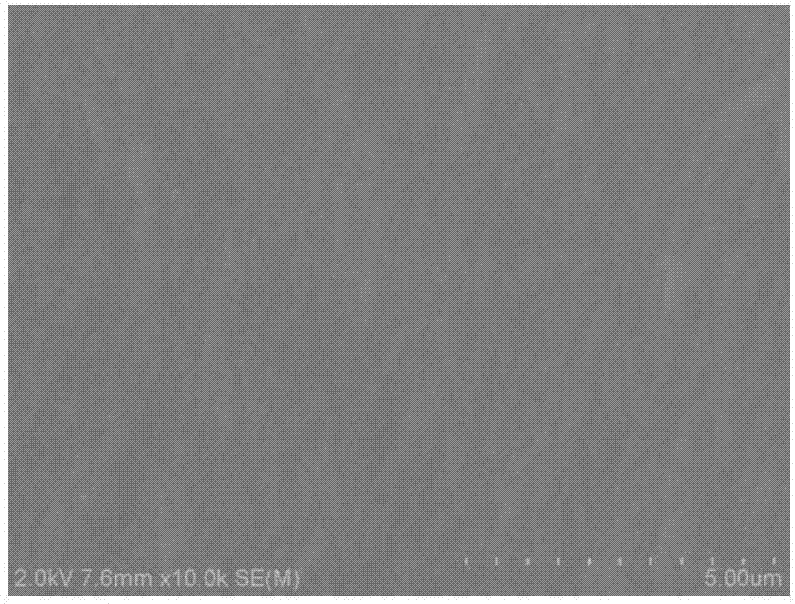

[0025] Preparation of aqueous polyurethane emulsion and film: Add 25.1g isophorone diisocyanate (IPDI) in a 1000mL four-necked flask equipped with a stirrer, thermometer and reflux condenser, and add 70.0 g of isophorone diisocyanate (IPDI) dropwise with a dropping funnel while stirring at room temperature. g polycarbonate multi-component (PCDL2000) and 0.15g catalyst dibutyltin dilaurate (DBTDL), the dropping rate is controlled within 1.5h, after the addition is completed, react at 50±5°C for 1-2h; then heat up to 60±5°C , add 4.96g dimethylolpropionic acid (DMPA), react for 5-6h, measure the degree of reaction by the toluene-di-n-butylamine back titration method, until the NCO group content reaches the theoretical value; then add 2.10g to the resin Potassium hydroxide, reacted for 1.5h; Add deionized water dropwise to the system to emulsify; Form a film, dry to obtain a water-based polyurethane film, and perform a tensile property test on the film (such as image 3 ) and SEM...

Embodiment 2

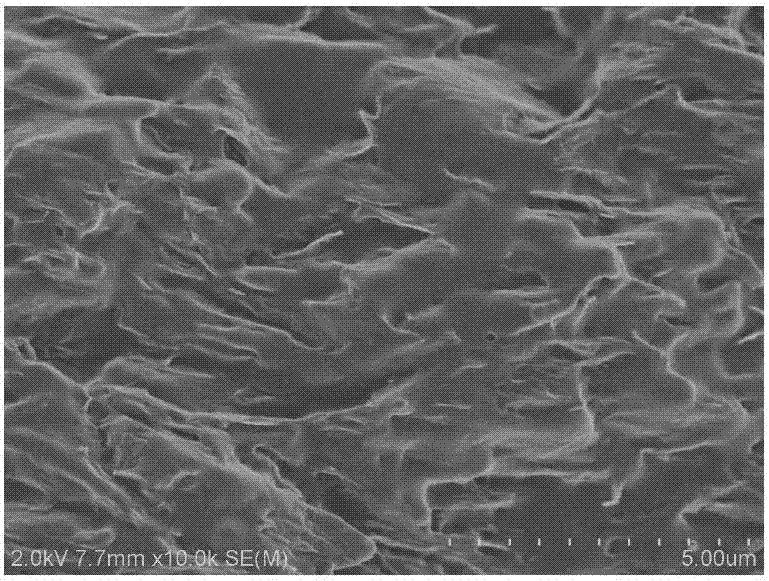

[0027] Preparation of water-based polyurethane graphene nanocomposite emulsion and composite film: add 25.1g isophorone diisocyanate (IPDI) in a 1000mL four-necked flask equipped with a stirrer, thermometer and reflux condensing tube, and use dropwise while stirring at room temperature Add 70.0g of polycarbonate polyol (PCD2000) and 0.15g of catalyst dibutyltin dilaurate (DBTDL) dropwise into the liquid funnel, and the dropping rate is controlled within 1.5h. After the dropping is completed, react at 50±5°C for 1-2h; then Raise the temperature to 60°C, add 4.96g dimethylol propionic acid (DMPA), react for 5-6h, measure the reaction degree by the toluene-di-n-butylamine back titration method, until the NCO group content reaches the theoretical value; then add to the resin Add 2.10g of potassium hydroxide to the solution, and react for 1.5h; properly adjust the viscosity, add it dropwise into 200mL of graphene oxide dispersion (mixture of water and DMF, 10mg / mL), and react with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com