Method for extracting arteannuin B from herba artemisiae annuae

A technology of artemisinin and artemisinin, which is applied in the field of preparation of natural medicinal chemistry, can solve problems such as difficulty in obtaining pure artemisinin, difficulty in industrial production, complex synthesis methods, etc., and achieves suitable for large-scale production and short separation cycle , High extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

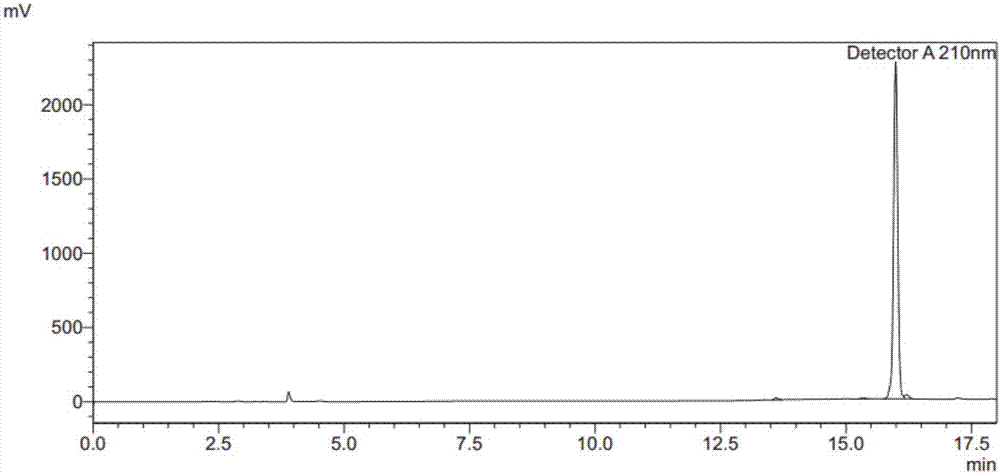

Image

Examples

Embodiment 1

[0029] 1) Take 10Kg of Artemisia annua medicinal material, crush it with a pulverizer, soak the crushed medicinal material with 20L of 100% methanol for 12 hours to obtain a soaking solution;

[0030] 2) Use the D-101 macroporous adsorption resin column to carry out rough separation of the soaking liquid in step 1), and the rough separation refers to eluting the macroporous adsorption resin with volume fractions of 70%, 80% methanol aqueous solution and 100% methanol successively Columns, the elution volumes are 2, 4 and 3 column volumes respectively, and the eluents with a combined volume fraction of 80% methanol aqueous solution are collected. The flow rate of each eluent is 2 column volumes / hour, and every 500ml is 1 elution fraction, and the target eluent is analyzed and collected by high-performance liquid chromatography (HPLC), and the obtained artemisinin enriched solution . Part of the methanol solvent was removed from the artemisinin-enriched solution by vacuum disti...

Embodiment 2

[0037] 1) Take 10Kg of Artemisia annua medicinal material, crush it with a pulverizer, soak the crushed medicinal material in 15L of 100% methanol for 12 hours to obtain soaking solution 1, then soak in 15L of 100% methanol for 12 hours to obtain soaking solution 2, and combine the soaking solutions 1, 2, to obtain the total soaking solution.

[0038] 2) Use the D-101 macroporous adsorption resin column to carry out rough separation of the soaking liquid in step 1), and the rough separation refers to eluting the macroporous adsorption resin with volume fractions of 70%, 90% methanol aqueous solution and 100% methanol successively Columns, the elution volumes are 2, 4 and 3 column volumes respectively, and the eluents with a combined volume fraction of 90% methanol aqueous solution are collected. The flow rate of each eluent is 2 column volumes / hour, and every 500ml is 1 elution fraction, and the target eluent is analyzed and collected by high-performance liquid chromatography ...

Embodiment 3

[0045] 1) Take 10Kg of Artemisia annua medicinal material, crush it with a pulverizer, soak the crushed medicinal material with 25L of 100% methanol for 24 hours to obtain a soaking solution.

[0046] 2) Use the D-101 macroporous adsorption resin column to carry out rough separation of the soaking liquid in step 1), and the rough separation refers to eluting the macroporous adsorption resin with volume fractions of 70%, 86% methanol aqueous solution and 100% methanol successively Columns, the elution volumes are 2, 4 and 3 column volumes respectively, and the eluents with a combined volume fraction of 86% methanol aqueous solution are collected. The flow rate of each eluent is 2 column volumes / hour, and every 500ml is 1 elution fraction, and the target eluent is analyzed and collected by high-performance liquid chromatography (HPLC), and the obtained artemisinin enriched solution . Dilute the artemisinin enriched solution with pure water (the volume ratio of pure water to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com