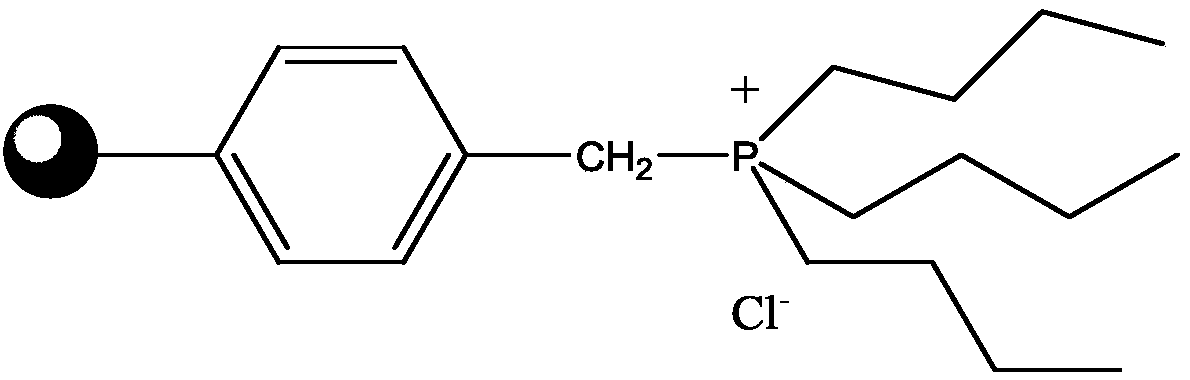

Method for separating platinum and rhodium from alkaline cyanide solution by using polystyrene-tributyl quaternary phosphonium resin

A technology of tributyl quaternary phosphine and polystyrene, which is applied in the field of separating platinum and rhodium, can solve the problems of no industrial-scale application, small adsorption capacity, and long equilibrium time, and achieve easy control of adsorption and separation conditions and high adsorption capacity Large and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Immobilization of Rh(CN) under different pH conditions at room temperature 6 3- The concentration of Rh(III) in the solution is 2.5g / L, the amount of PS-BQP in the stationary phase is 1.0g, the solid-liquid ratio is 1:100 (g / mL), shake for 30min, and filter out the loaded PS-BQP; measure Rh( III) Adsorption amount, pH value on PS-BQP adsorption of Rh(CN) 6 3- The impact is shown in Table 1.

[0026] Table 1. Effect of pH value on adsorption of Rh(CN) by PS-BQP 6 3- Impact

[0027]

[0028]

Embodiment 2

[0030] Immobilization of Pt(CN) under different pH conditions at room temperature 4 2- The concentration of Pt(II) in the solution is 3.0g / L, the amount of PS-BQP in the stationary phase is 1.0g, the solid-liquid ratio is 1:100 (g / mL), shaken for 30min, and the loaded PS-BQP is filtered out; Determination of Pt( II) Adsorption capacity, pH value on PS-BQP adsorption of Pt(CN) 4 2- The impact is shown in Table 2.

[0031] Table 2. Effect of pH value on adsorption of Pt(CN) by PS-BQP 4 2- Impact

[0032] pH value

[0033] It can be seen from Table 1 and Table 2 that the PS-BQP adsorbent has a wide range of pH in the range of 9.0 to 11.0 for Pt(CN) 4 2- and Rh(CN) 6 3- All have better adsorption effect.

Embodiment 3

[0035]At room temperature, weigh 1.0g resin as stationary phase, add to pH=10.5, 100mL Rh(CN) 6 3- In the solution, the concentration of Rh(III) was 2.5g / L, shaken for 30min, and the loaded PS-BQP was filtered out; the adsorption amount of Rh(III) was measured, and the filtered resin loaded with Rh(III) was added to 50mL at 1.0mol / In the L KCI solution, shake for 15min, filter out the PS-BQP in the desorption solution, wash the PS-BQP twice with distilled water, and absorb the same Rh(CN) again 6 3- solution, the measurement results of static adsorption capacity for 6 cycles are shown in Table 3.

[0036] Table 3. Determination of Cyclic Static Adsorption Capacity of Rh(III)

[0037] Cycles

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com