Synthetic method of decoquinate

A synthesis method and a decoquinate technology, applied in the field of pharmaceutical engineering, can solve the problems of high reaction risk, high production cost, heavy metal pollution, etc., and achieve the effects of good selectivity, low cost, and reduced equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

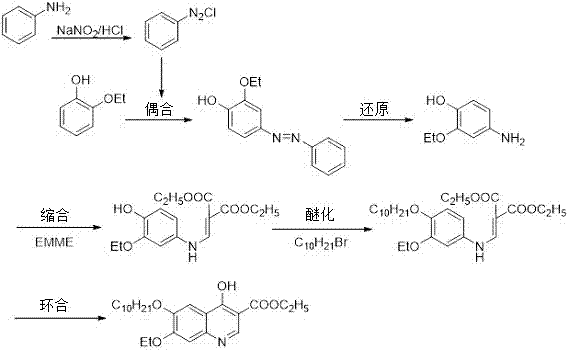

Method used

Image

Examples

Embodiment 1

[0029] Step A. Coupling process: Add 27.9 kg of aniline and 60 L of water into the first reaction kettle, pass through frozen brine to cool, the temperature of the ice bath is 0°C, add 72 L of concentrated hydrochloric acid, wait until the temperature drops below 2°C after adding, Add 83 kg of 25% sodium nitrite solution dropwise, keep the internal temperature at 5°C during the dropwise addition, and continue to stir and react for 1.5 hours after the dropwise addition to obtain aniline diazonium salt for later use.

[0030] Add 41.4 kg of o-hydroxyphenethyl ether and 220 L of ethanol to the second reaction kettle, and adjust the pH to about 7 with saturated sodium carbonate solution. After cooling, the aniline diazonium salt solution prepared in the first reaction kettle is added dropwise in the second reaction kettle, the temperature of the diazonium salt solution is kept below 5°C during the dropwise addition, and saturated sodium carbonate solution is added dropwise at the s...

Embodiment 2

[0036] Step A. Coupling process: Add 18.6 kg of aniline and 40 L of water into the first reaction kettle, pass in frozen brine to cool, the temperature of the ice bath is 0°C, add 48 L of concentrated hydrochloric acid, wait until the temperature drops to about 0°C after adding, Add 57 kg of 25% sodium nitrite solution dropwise, keep the internal temperature at 0°C during the dropwise addition, and continue to stir and react for 1 hour after the dropwise addition, to obtain aniline diazonium salt for later use.

[0037] Add 27.6 kg of o-hydroxyphenethyl ether and 150 L of ethanol to the second reaction kettle, adjust the pH to about 8 with saturated sodium carbonate solution, and cool down. Add the aniline diazonium salt solution prepared in the first reaction kettle dropwise to the second reaction kettle, keep the temperature of the diazonium salt solution at 4~5°C during the dropping process, and simultaneously add saturated sodium carbonate solution dropwise to maintain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com