High-pressure decorative door sheet comprising wood base materials and preparation method of door sheet

A wood-based, high-pressure technology, applied in lamination devices, wood layered products, chemical instruments and methods, etc., can solve problems such as high hardness, fire prevention, poor sound insulation effect, and easy edge chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation raw material ratio of the melamine-formaldehyde resin used in the preparation process of the impregnated surface paper for bonding is: the molar ratio of melamine and formaldehyde is 1:1.65, the quality of caprolactam is 13.5% of the quality of melamine, the quality of diethylene glycol 18% of the quality of melamine, the quality of sucrose is 1.5% of the quality of melamine, and the quality of thiourea is 2.2% of the quality of melamine; the preparation method of this melamine formaldehyde resin comprises the following steps: 1. adding metered formaldehyde in the reactor, Add water to adjust its mass concentration to 30%, then adjust the pH value of the solution to 9.2 to 9.5 with a 30% sodium hydroxide aqueous solution, start heating, and after the temperature is raised from room temperature to 40°C, add the measured Melamine, thiourea and sucrose, and the solution becomes clear when the temperature continues to rise to 70°C; ②After the solution becomes...

Embodiment 1

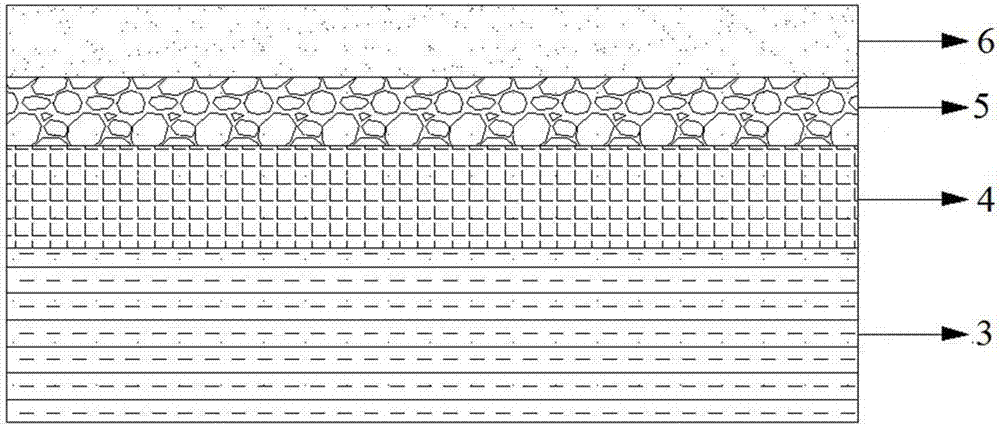

[0069] A kind of wooden substrate high-pressure decorative door panel according to the present invention, such as figure 2 As shown, the decorative door panel includes a substrate layer 3, a buffer layer 4 disposed on the substrate layer 3, a decorative layer 5 disposed on the buffer layer 4, and a wear-resistant protective layer 6 disposed on the decorative layer 5; A layer of impregnated surface paper layer for bonding is added between the substrate layer 3 and the buffer layer 4;

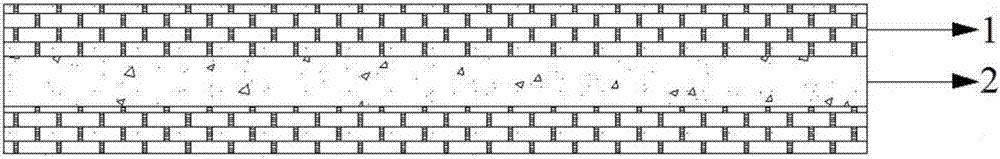

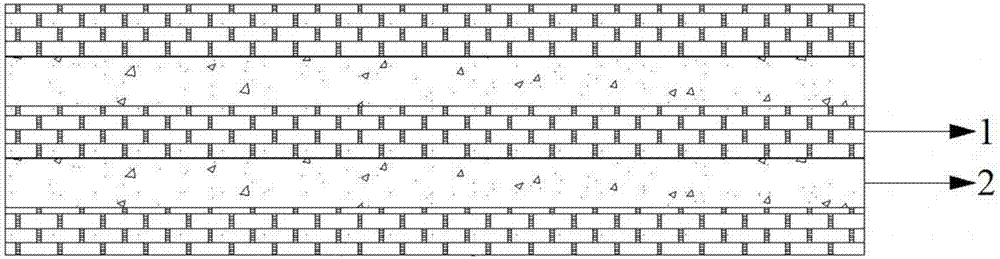

[0070] Such as figure 1 As shown, the substrate layer 3 includes at least two layers of wood substrate ply 1 (thickness of the wood substrate layer is 0.2-0.5mm) after flame retardant treatment, and the wood substrate layer 1 after flame retardant treatment An impregnated surface paper layer 2 for bonding is provided between the layers (that is, a layer of impregnated surface paper layer for bonding is provided between every two layers of wood substrate layers that have undergone flame-retardan...

Embodiment 2

[0079] The decorative layer of this embodiment is pressed with a hemp surface treatment and a louver-shaped mold.

[0080] A method for preparing a high-pressure decorative door panel with a wooden base material, comprising the following steps:

[0081] (1) Preparation of substrate layer

[0082] a.: Preparation of flame retardant liquid: uniformly mix ammonium polyphosphate, ammonium dihydrogen phosphate, and diammonium hydrogen phosphate according to the mass ratio of 1:1:1 to obtain a mixture, and then according to the mass ratio of the mixture to water as 1: 3, mixed evenly, heated to 40°C and stirred evenly, and the flame retardant liquid was prepared;

[0083] b. Flame retardant treatment of wood substrates: dry Chinese fir veneer in a wood drying room at 60-80°C until the moisture content is below 6%, then enter the pressure impregnation tank equipped with the fire retardant solution prepared in step a, add Pressurize to 0.4-0.48MPa, pressurize for 40 minutes and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com