Strontium titanate/tin niobate composite nanometer material preparation method

A technology for composite nanomaterials and composite materials, applied in the field of preparation of strontium titanate/tin niobate composite nanomaterials, achieving the effects of simple preparation process, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

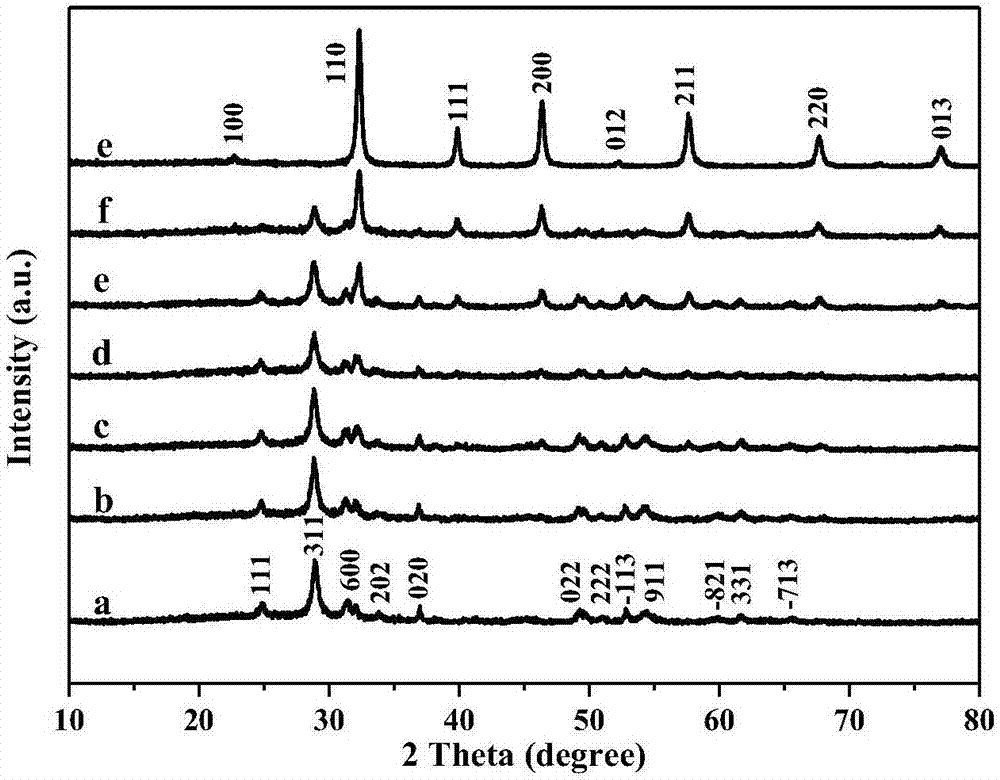

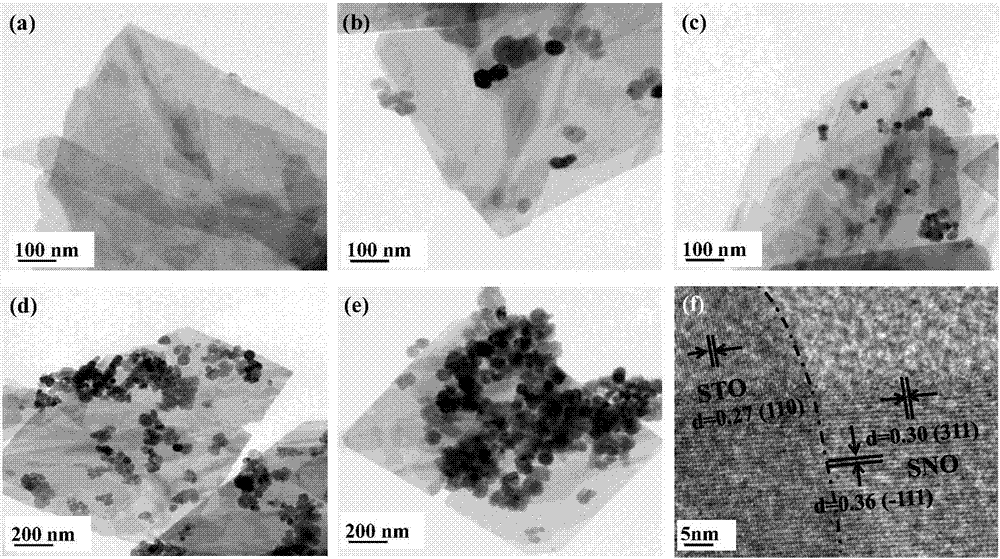

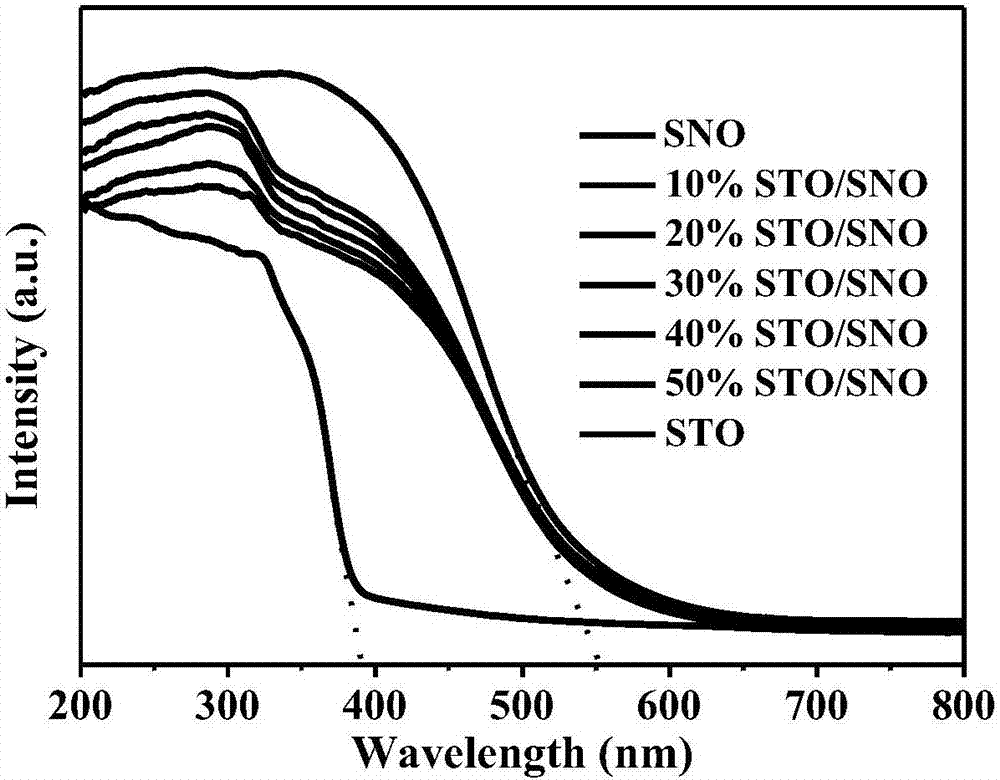

[0033] Example 1 SnNb 2 o 6 Preparation of nanosheets

[0034] SnNb 2 o 6 The preparation adopts the method of hydrothermal reaction: Weigh 0.5g of niobium pentoxide and 2.2443g of potassium hydroxide in a 50mL reactor lined with polytetrafluoroethylene, add 35mL of deionized water to it, and put the reactor Put it in an oven and react with water at 180°C for 48 hours. After naturally cooling to room temperature, a clear precursor solution is obtained. Transfer the solution to a 50mL beaker, adjust the pH of the solution to 8 with a concentration of 2mol / L dilute hydrochloric acid, and then add 0.4245g Stannous chloride dihydrate, stirred by magnetic force for 10min, adjusted the pH of the solution to 2 with dilute hydrochloric acid with a concentration of 2mol / L again, transferred the solution to a 100mL reaction kettle lined with polytetrafluoroethylene, put it into an oven, and heated it with water at 200℃. Thermally react for 48 hours, cool to room temperature, centrif...

Embodiment 2

[0035] Example 2 SrTiO 3 Preparation of nanoparticles

[0036] SrTiO 3 The preparation adopts the method of hydrothermal reaction: Measure 10mmol of tetrabutyl titanate and dissolve it in 20ml of ethylene glycol, stir it magnetically for 10min to form a clear solution, then add 20ml of 0.5M strontium nitrate solution and 10ml of 5M sodium hydroxide solution, magnetic Stir for 30 minutes, transfer the solution to a 100mL reaction kettle lined with polytetrafluoroethylene, put it in an oven, conduct a hydrothermal reaction at 200°C for 24 hours, cool to room temperature, centrifuge to obtain white particles, wash with water and alcohol until neutral, and centrifuge. Dry in an oven at 60°C for 12h.

Embodiment 3

[0037] Example 3 10%-SrTiO 3 / SnNb 2 o 6 Preparation of composite materials

[0038] SrTiO 3 / SnNb 2 o 6 The preparation of the composite material adopts a two-step wet chemical method: weigh 50mg SnNb 2 o 6 Dissolve in 60ml absolute ethanol, 5.6mg SrTiO 3 The powder was dissolved in 20ml of absolute ethanol, and then ultrasonicated in an ultrasonic machine with a power of 250W for 30min, and then the SrTiO 3 The solution was added dropwise to SnNb 2 o 6 The solution was magnetically stirred for 4 hours, and the solution was transferred to a 100mL reaction kettle lined with polytetrafluoroethylene, placed in an oven, and subjected to a hydrothermal reaction at 160°C for 12 hours. After cooling to room temperature naturally, the yellow particles were centrifuged, washed with water and After washing with alcohol three times, centrifuge and dry in an oven at 60°C for 12 hours to obtain the 10%-SrTiO 3 / SnNb 2 o 6 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com