Energy-storing and multi-functional coating and preparation method thereof

A multi-functional, coating technology, applied in the field of coatings, can solve the problems of poor temperature adjustment and temperature control effect of coatings, high phase change enthalpy of products, high bonding strength, etc. The effect of stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

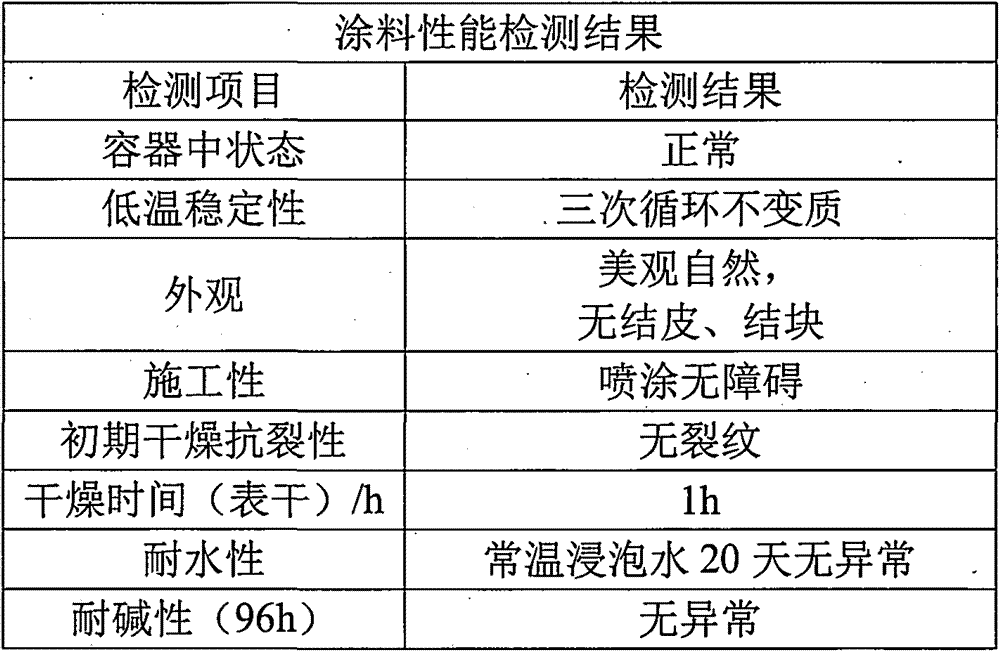

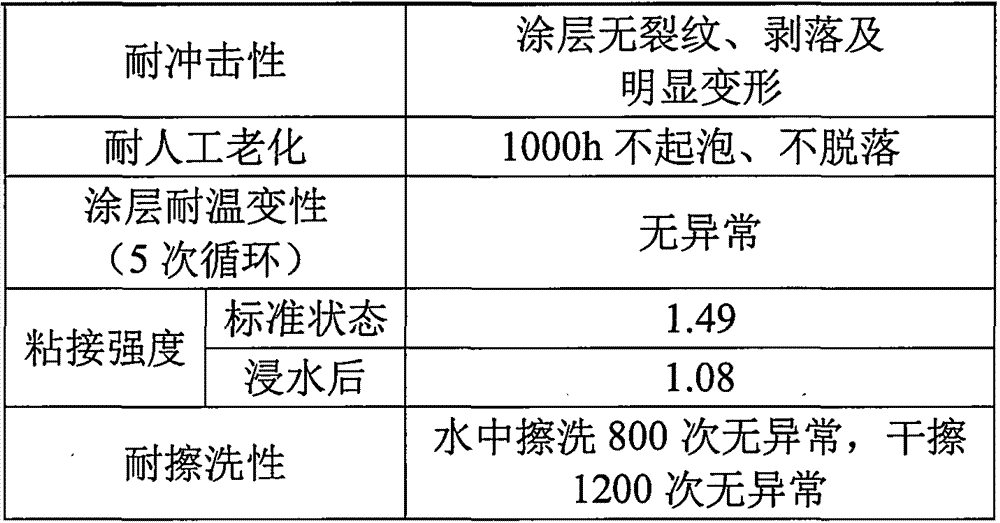

[0026] The raw material formula is shown in the following table:

[0027] serial number

parts by weight

1

15

2

Phase Change Microcapsule Suspension

75

3

Silica airgel

1

4

6

5

2

6

Modified sodium disilicate

0.1

7

Wetting and dispersing agent

0.1

8

0.3

9

water

10

[0028] The phase-change microcapsule suspension is prepared by the following preparation method: (1) mixing styrene-maleic anhydride random copolymer, sodium hydroxide and water, heating and stirring to dissolve, adjusting the pH value of the solution to 5 with citric acid, Then mix with paraffin, shear and emulsify to obtain paraffin wax emulsion; (2) mix melamine, formaldehyde aqueous solution and water, adjust the pH value to 9 with triethanolamine, heat up, and then add carboxymethyl cellulose to r...

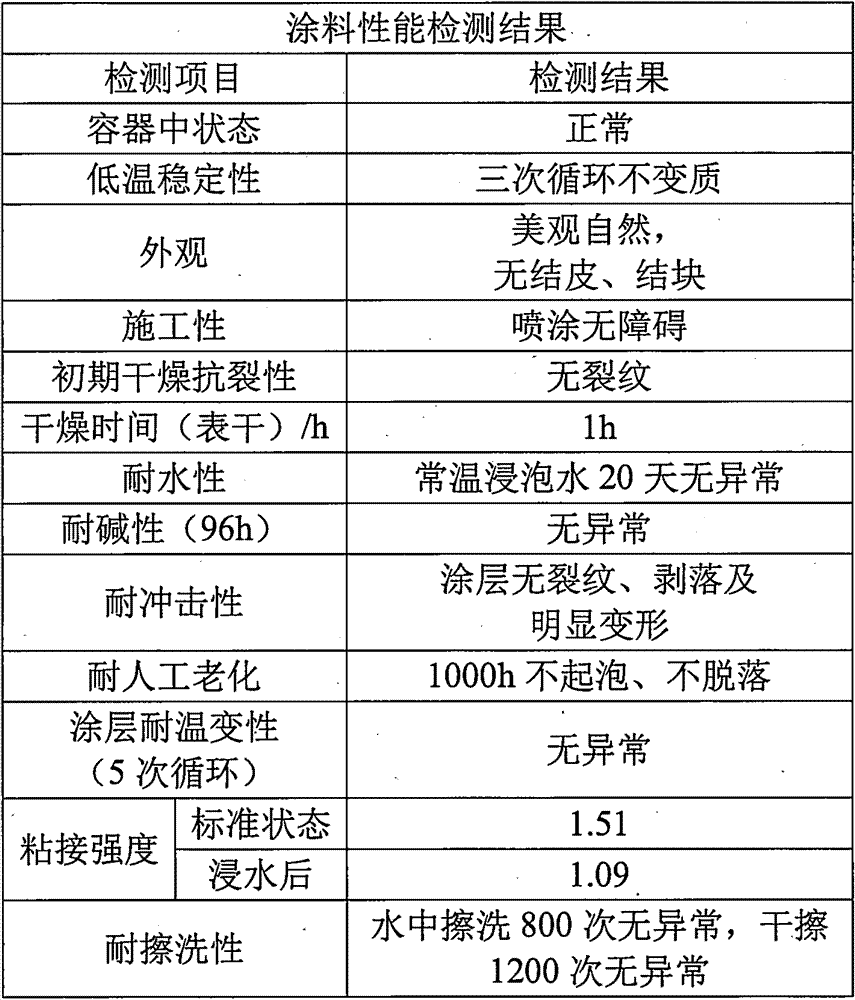

Embodiment 2

[0036] The raw material formula is shown in the following table:

[0037] serial number

parts by weight

1

polymer emulsion

17

2

Phase Change Microcapsule Suspension

90

3

Silica airgel

2

4

8

5

3

6

Modified sodium disilicate

0.2

7

Wetting and dispersing agent

0.2

8

0.4

9

water

8

[0038] The phase-change microcapsule suspension is prepared by the following preparation method: (1) mixing styrene-maleic anhydride random copolymer, sodium hydroxide and water, heating and stirring to dissolve, adjusting the pH value of the solution to 6 with citric acid, Then mix with paraffin, shear and emulsify to obtain paraffin wax emulsion; (2) mix melamine, formaldehyde aqueous solution and water, adjust the pH value to 10 with triethanolamine, heat up, and then add carboxymethyl cellulose to r...

Embodiment 3

[0045] The raw material formula is shown in the following table:

[0046] serial number

parts by weight

1

20

2

Phase Change Microcapsule Suspension

85

3

Silica airgel

2

4

polyvinyl alcohol

7

5

5

6

Modified sodium disilicate

0.1

7

Wetting and dispersing agent

0.3

8

0.3

9

water

6

[0047] The phase-change microcapsule suspension is prepared by the following preparation method: (1) mixing styrene-maleic anhydride random copolymer, sodium hydroxide and water, heating and stirring to dissolve, adjusting the pH value of the solution to 5 with citric acid, Then mix with paraffin, shear and emulsify to obtain paraffin wax emulsion; (2) mix melamine, formaldehyde aqueous solution and water, adjust the pH value to 9 with triethanolamine, heat up, and then add carboxymethyl cellulose to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com