Method for synthesizing super-long solid carbon fiber by self-catalyzed chemical vapor deposition

A chemical vapor deposition and self-catalysis technology, which is applied in gaseous chemical plating, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of system sealing, increase process operation steps, loss of catalytic effect, etc., and achieve low cost, The synthesis process is simple and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Put the high-purity graphite paper with a thickness of 0.5 mm as the substrate into the central heating zone of the tube furnace; use a vacuum pump to exhaust the air in the tube, and then inject hydrogen into the tube, and under the hydrogen flow atmosphere, the temperature is 5 °C / min heating tube furnace to 1200°C;

[0036] (2) Set the flow rates of methane gas, hydrogen gas and argon gas to 72 sccm, 202 sccm and 281 sccm respectively, feed methane gas, hydrogen gas and argon gas into the tube furnace at the same time, and keep the furnace temperature at 1200°C for 2 h;

[0037] (3) After the heat preservation is over, stop feeding methane and hydrogen, and only let argon continue to flow into the tube furnace at a flow rate of 84 sccm, so that the temperature of the tube furnace naturally drops to room temperature, and a super Long solid carbon fiber.

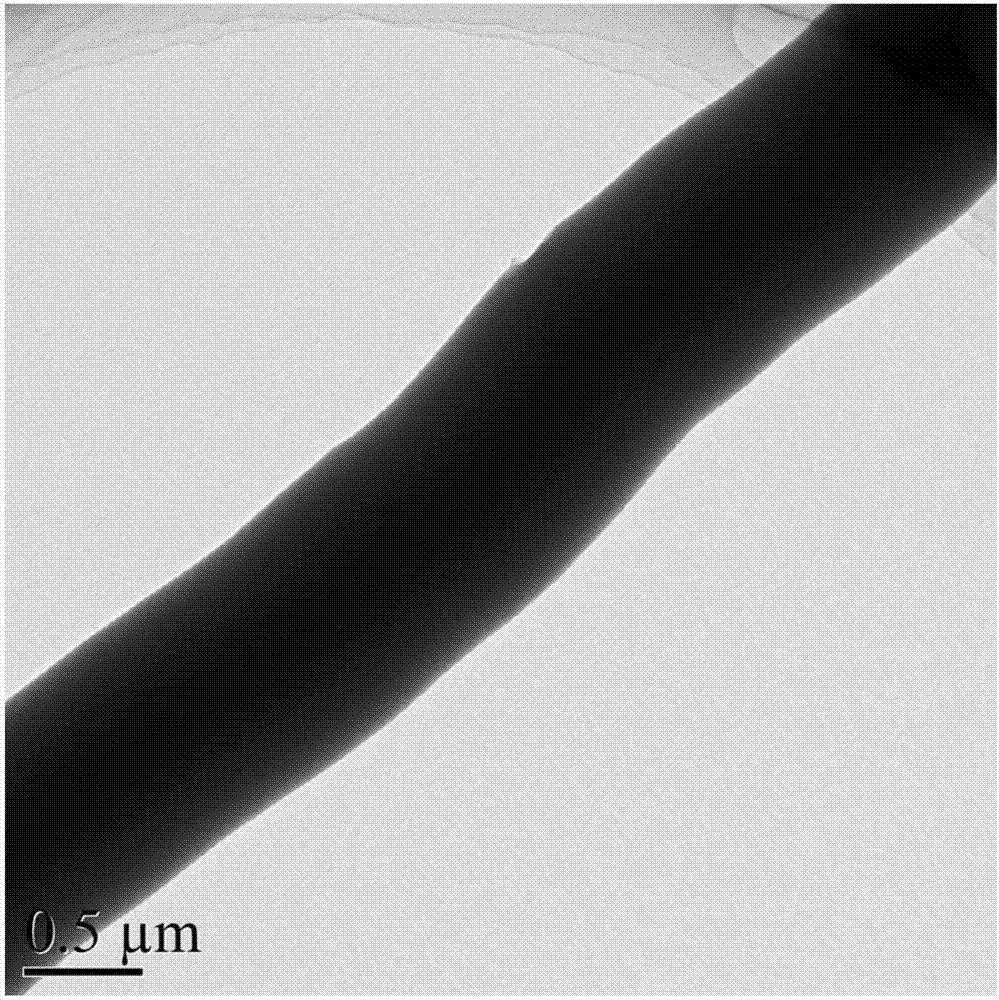

[0038] The synthetic ultra-long solid carbon fiber was observed by transmission electron microscope and its...

Embodiment 2

[0040] (1) Put the glazed porcelain ark as the substrate in the central heating zone of the tube furnace; use a vacuum pump to exhaust the air inside, then inject hydrogen into the tube, and heat the tube at 5°C / min under the hydrogen flow atmosphere type furnace to 1100°C;

[0041] (2) Set the flow rates of methane gas, hydrogen gas and argon gas to 60 sccm, 220 sccm and 260 sccm respectively, feed methane gas, hydrogen gas and argon gas into the tube furnace at the same time, and keep the furnace temperature at 1100°C for 30 min;

[0042] (3) After the heat preservation is over, stop feeding methane and hydrogen, and only let argon continue to flow into the tube furnace at a flow rate of 60 sccm, so that the temperature of the tube furnace naturally drops to room temperature, and grow super Long solid carbon fiber.

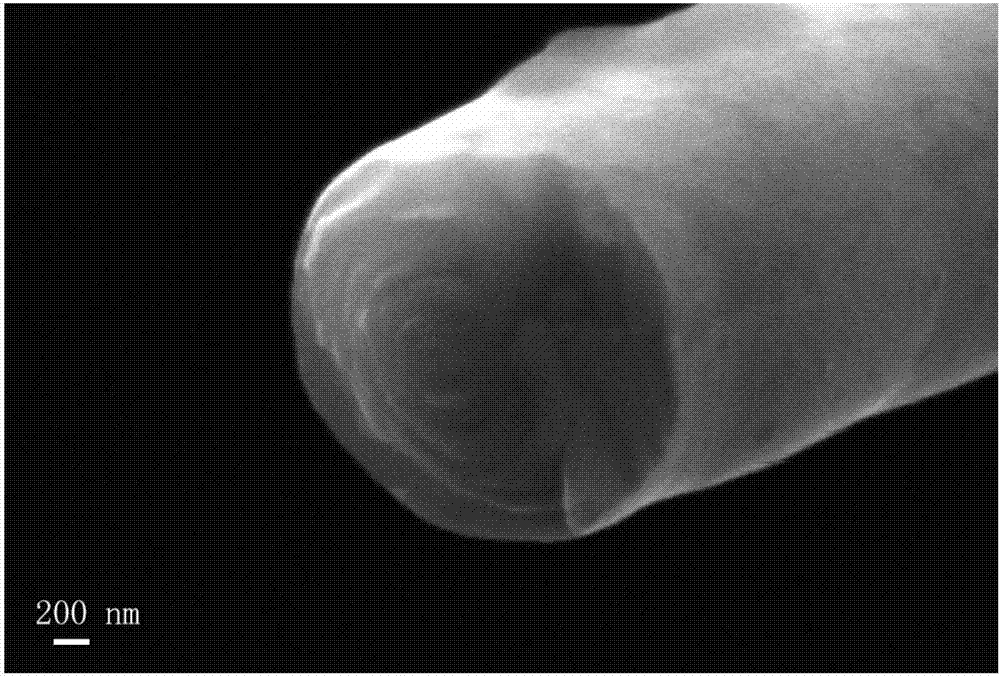

[0043] The morphology and tip of the synthesized ultra-long solid carbon fiber were observed with a scanning electron microscope, and the elemental analysis w...

Embodiment 3

[0045] (1) Put the high-purity graphite paper with a thickness of 0.5 mm as the substrate into the central heating zone of the tube furnace; use a vacuum pump to exhaust the air in the tube, and then pass hydrogen into the tube, and under the hydrogen flow atmosphere, the temperature is 5 ° C / min heating tube furnace to 1250°C;

[0046] (2) Set the flow rates of methane gas, hydrogen gas and argon gas to 55 sccm, 210 sccm and 300 sccm respectively, feed methane gas, hydrogen gas and argon gas into the tube furnace at the same time and keep the furnace temperature at 1250 °C for 3 h ;

[0047] (3) After the heat preservation is over, stop feeding methane and hydrogen, and only let argon continue to flow into the tube furnace at a flow rate of 100 sccm, so that the temperature of the tube furnace naturally drops to room temperature, and grow super Long solid carbon fiber.

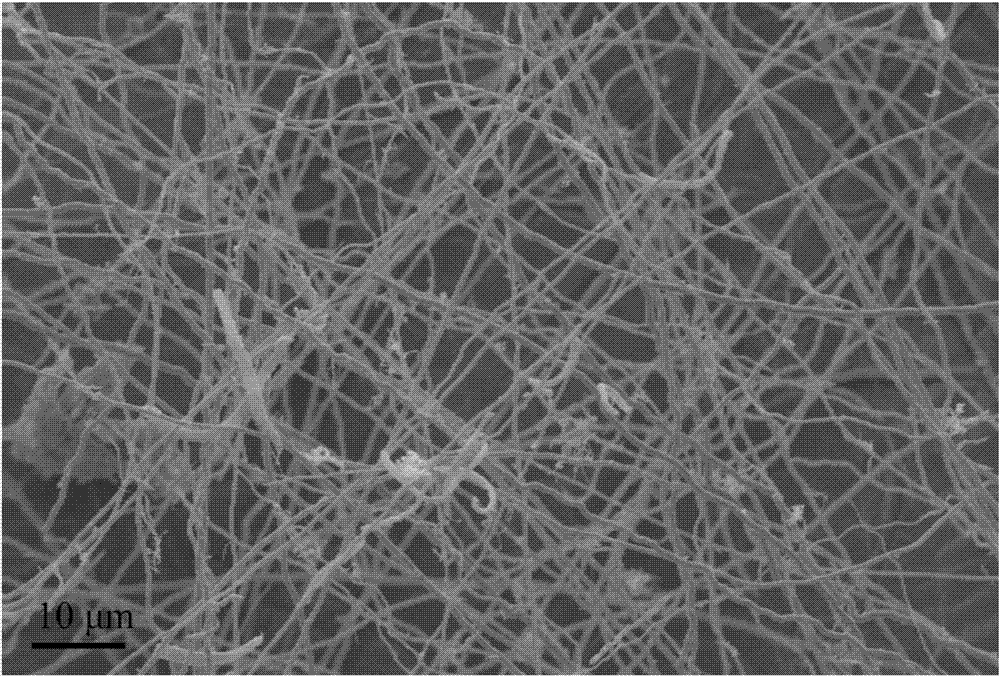

[0048] The morphology of the synthesized ultra-long solid carbon fibers was observed by scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com