Lead-gallium-germanium-sulfur crystal and preparing method and application thereof

A crystal and lead source technology, applied in the field of inorganic nonlinear optical materials, can solve the problem that the laser damage threshold needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh in air, take 0.45mmol lead chloride (0.125g), 0.05mmol lead sulfide (0.012g), 0.3mmol digallium trisulfide (0.071g) and 0.3mmol germanium disulfide (0.041g) fully Grinding and mixing;

[0045] (2) Put the above samples into a quartz tube with one end closed, and connect it to a vacuum line to evacuate and seal the tube with a vacuum degree of 0.01-10Pa;

[0046] (3) Heat the above vacuum-sealed quartz tube in a resistance furnace, keep it at 550°C for 100h, and then cool it down to room temperature at a rate of 5°C / h. When the tube is opened, it can be seen that there are light yellow transparent block crystals attached to the tube wall or at the bottom, which are lead gallium germanium sulfur crystals.

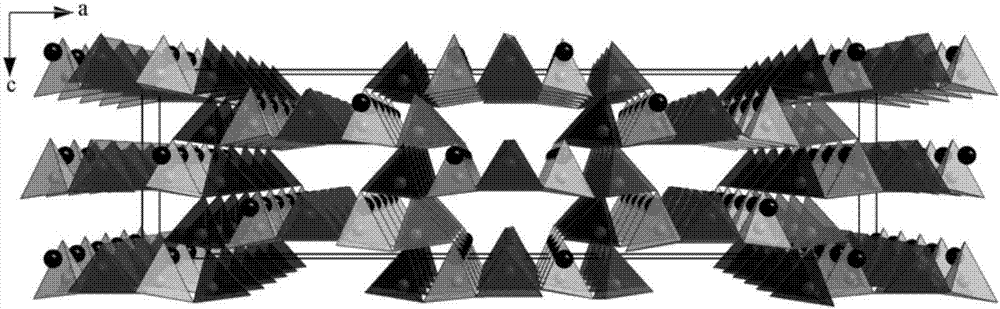

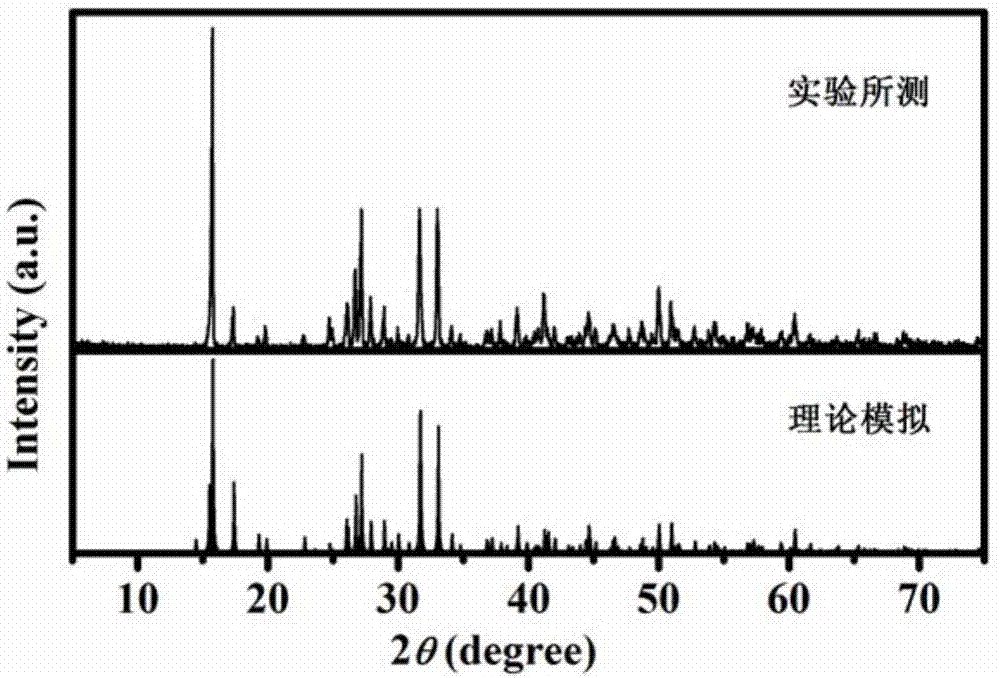

[0047] The prepared lead gallium germanium sulfur crystal is tested by a single crystal diffractometer, the crystal is orthorhombic, the space group is Fdd2, and the unit cell parameters are: α=90°, β=90°, γ=90°, Z=16.

[0048] The prepared lead galli...

Embodiment 2

[0050] (1) Weigh in air, get 0.5mmol lead chloride, 0.3mmol gallium trisulfide and 0.3mmol germanium disulfide and fully grind and mix;

[0051] (2) Put the above samples into a quartz tube with one end closed, and connect it to a vacuum line to evacuate and seal the tube with a vacuum degree of 0.01-10Pa;

[0052] (3) Heat the above vacuum-sealed quartz tube in a resistance furnace, keep it at 500° C. for 24 hours, and then cool it down to room temperature at a rate of 0.1° C. / h. When the tube is opened, it can be seen that there are light yellow transparent block crystals attached to the tube wall or at the bottom, which are lead gallium germanium sulfur crystals.

[0053] The crystal structure identification data are the same as in Example 1.

Embodiment 3

[0055] (1) Weigh in air, get 0.45mmol lead chloride, 0.05mmol lead sulfide, 0.3mmol gallium trisulfide and 0.3mmol germanium disulfide and fully grind and mix;

[0056] (2) Put the above samples into a quartz tube with one end closed, and connect it to a vacuum line to evacuate and seal the tube with a vacuum degree of 0.01-10Pa;

[0057] (3) Heat the above vacuum-sealed quartz tube in a resistance furnace, keep it at 650° C. for 60 hours, and then cool it down to room temperature at a rate of 10° C. / h. When the tube is opened, it can be seen that there are light yellow transparent block crystals attached to the tube wall or at the bottom, which are lead gallium germanium sulfur crystals.

[0058] The crystal structure identification data are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative strength | aaaaa | aaaaa |

| Relative strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com