Photocatalyst and preparation method thereof

A technology of photocatalysts and nanowires, applied in the field of photocatalytic materials, to achieve wide application prospects, good photocatalysis and nonlinear optical properties, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

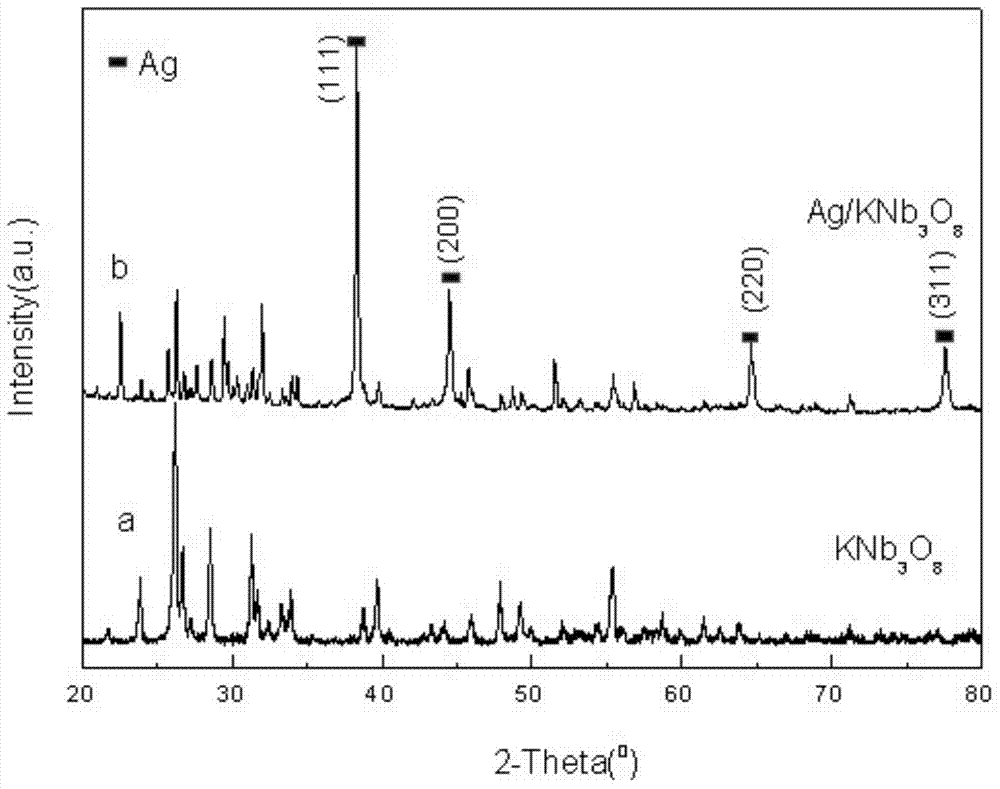

[0014] The preparation method of a kind of photocatalyst of the embodiment of the present invention comprises:

[0015] Step 1: Provide KNb 3 o 8 Nanowires;

[0016] Step 2: Add AgNO to ammonia solution 3 solution, stirred, adding the KNb 3 o 8 Nanowires, continue to stir, then add aldehyde-containing solution for silver mirror reaction, rinse after cooling, and obtain KNb coated with Ag nanoparticles 3 o 8 Nanowires.

[0017] Specifically, in step one, KNb 3 o 8 The preparation method of nanowires: at room temperature, weigh KCl and Nb according to a certain molar ratio 2 o 5 , ground in a mortar for 30 minutes, transferred to a crucible, calcined in a muffle furnace for 1 to 4 hours, cooled to room temperature, washed with water, filtered, and the filtrate was washed with distilled water until the pH value was equal to 7, then washed with ethanol Rinse and dry at 60-100°C for 5-12 hours to obtain KNb 3 o 8 Nanowires.

[0018] Specifically, in step two, KNb 3 o...

Embodiment 1

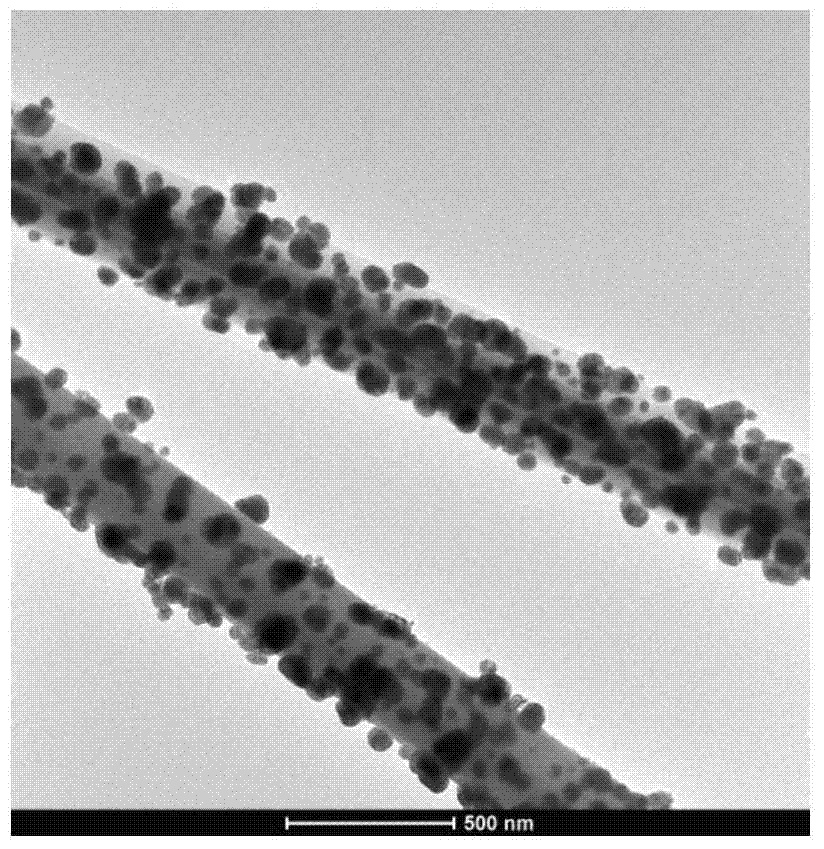

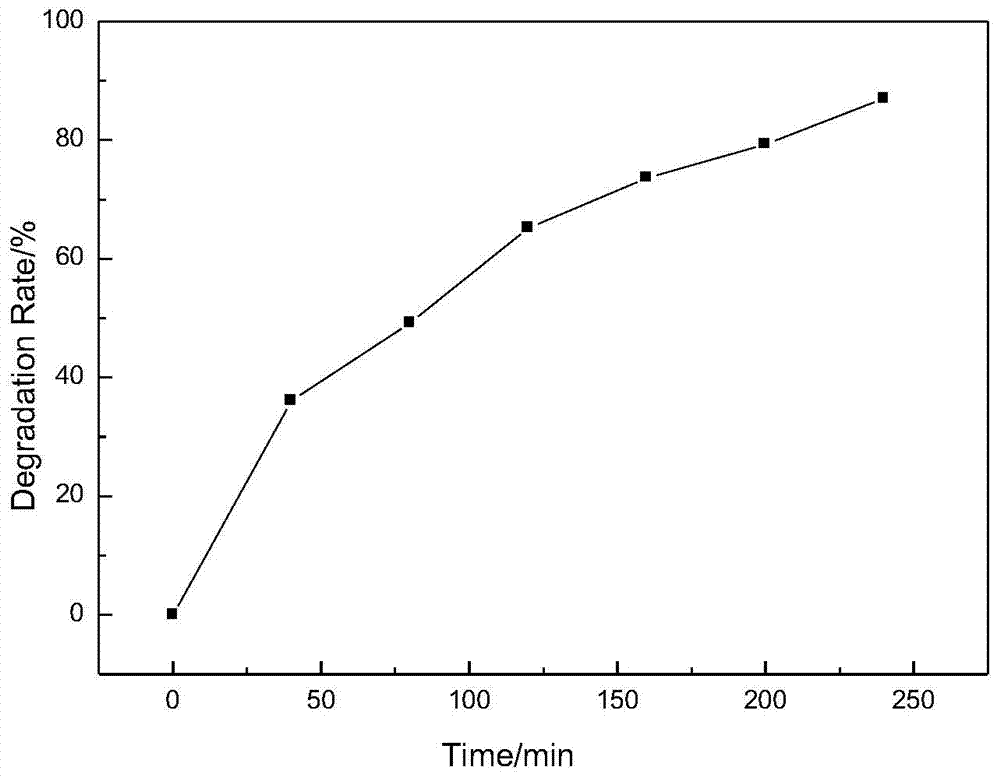

[0023] At room temperature (10-40°C), weigh 3.3048g of potassium chloride and 2.0086g of niobium pentoxide, and thoroughly grind and mix them in an agate mortar for 0.5 hours. Then move it into a ceramic crucible, put it into a muffle furnace and calcinate at a high temperature for 3 hours. The material was washed with distilled water until the pH value was equal to 7, and dried at 100 °C for 6 hours to obtain KNb 3 o 8 Nano stave. 1.5g AgNO 3 Add 50mL water and mix well, add 2.0wt% ammonia solution dropwise to the above AgNO 3 In the solution, stir with a magnetic stirrer until the solution is colorless, then add 0.2g KNb 3 o 8 Nanowires, continue magnetic stirring, then add 8.0mol / L formaldehyde solution at 60°C, react for 40min, cool to room temperature, wash with distilled water, then filter with a filter membrane with a filter hole diameter of 0.6μm, and filter the filtrate with distilled water After washing until the pH value is equal to 7, dry at 80 °C for 10 hour...

Embodiment 2

[0027] At room temperature (10-40°C), weigh 3.3048g of potassium chloride and 2.0086g of niobium pentoxide, and thoroughly grind and mix them in an agate mortar for 0.5 hours. Then move it into a ceramic crucible, put it into a muffle furnace and calcinate at a high temperature for 3 hours. The material was washed with distilled water until the pH value was equal to 7, and dried at 100 °C for 6 hours to obtain KNb 3 o 8 Nano stave. 2.0g AgNO 3 Add 50mL water and mix evenly, add 2.0% ammonia solution dropwise to the above AgNO 3 In the solution, stir with a magnetic stirrer until the solution is colorless, then add 0.2g KNb 3 o 8 Nanowires, continue magnetic stirring, then add 7.0mol / L formaldehyde solution at 60°C, react for 40min, cool to room temperature, wash with distilled water, then filter with a filter membrane with a filter hole diameter of 0.6μm, and filter the filtrate with distilled water After washing until the pH value is equal to 7, dry at 80°C for 10 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com