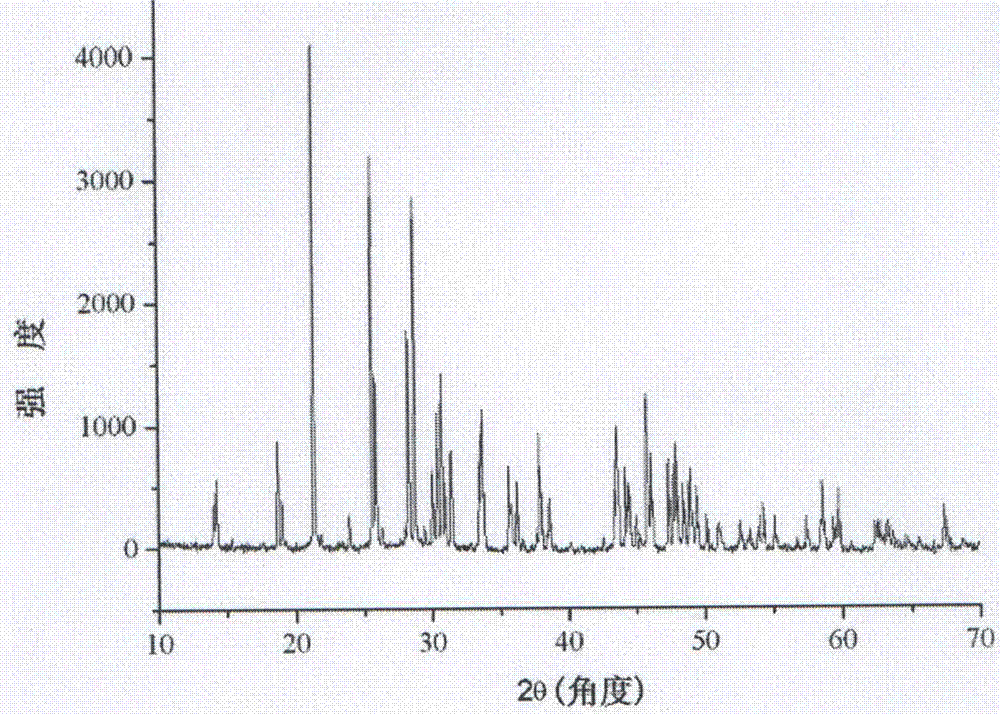

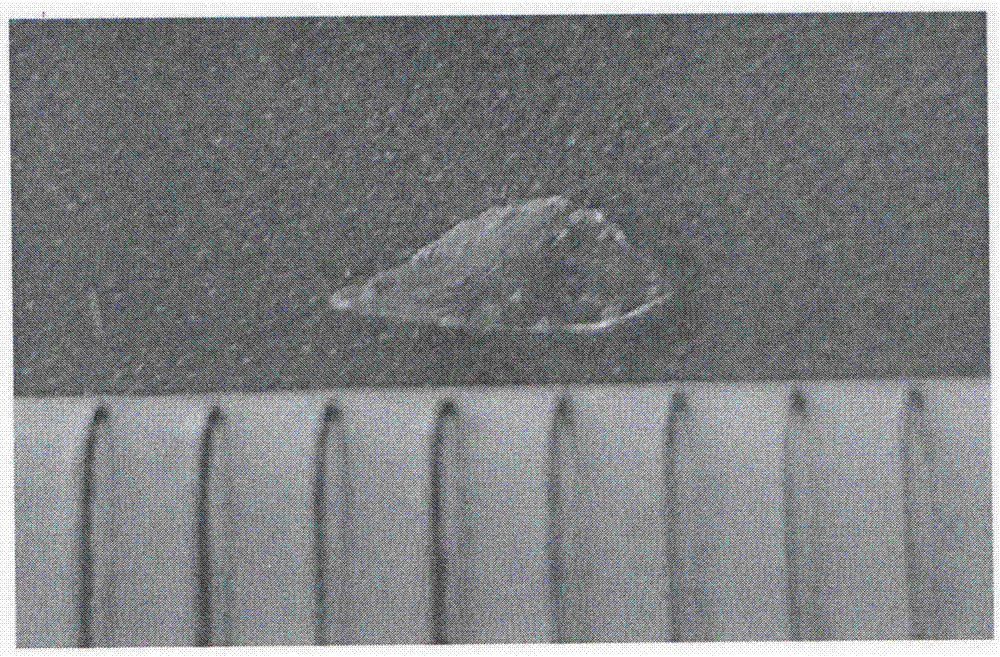

Method for preparing lead fluoroborate single crystal by microwave hydrothermal method

A lead fluoroborate and microwave hydrothermal technology, applied in the field of material science, can solve the problems of difficult control of the process, high price, and long experiment cycle, and achieve excellent nonlinear optical performance, low equipment cost, and short experiment cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. Analytical pure PbF 2 and H 3 BO 3 Mix at a molar ratio of 1:3, then dissolve in 0.2mol / L hydrofluoric acid, and keep stirring to make a suspension A with a Pb ion concentration of 0.1mol / L;

[0020] b. Add the mineralizer LiF into distilled water and keep stirring to prepare a transparent solution B with a Li ion concentration of 0.4mol / L;

[0021] c. Mix the suspension A obtained in step a with the transparent solution B obtained in step b in a molar ratio of Pb:Li=1:1 and stir evenly, then adjust the pH value of the solution to 9 with analytically pure LiOH, and fully Stir for 30min to obtain solution C;

[0022] d. Place the solution C obtained in step c in a hydrothermal reaction kettle, control the filling ratio to 40%, then put it into a temperature-pressure dual-control microwave hydrothermal reaction instrument, select the temperature control mode, and the temperature control temperature is 140°C. The reaction time is 1h, and the reaction is naturally co...

Embodiment 2

[0025] a. Analytical pure PbF 2 and H 3 BO 3 Mix at a molar ratio of 1:3, then dissolve in 0.1mol / L hydrofluoric acid, and keep stirring to make a suspension A with a Pb ion concentration of 0.5mol / L;

[0026] b. Add the mineralizer LiF into distilled water, and keep stirring to prepare a transparent solution B with a Li ion concentration of 0.1mol / L;

[0027] c. Mix and stir the suspension A obtained in step a and the transparent solution B obtained in step b in a molar ratio of Pb:Li=1:2, then use analytically pure LiOH to adjust the pH value of the solution to 10, and stir again for 60 minutes Obtain solution C;

[0028] d. Place the solution C obtained in step c in a hydrothermal reaction kettle, control the filling ratio to 40%, and then put it into a temperature-pressure dual-control microwave hydrothermal reactor, select the temperature control mode, and the temperature control temperature is 160°C. The reaction time is 2h, and the reaction is naturally cooled to ro...

Embodiment 3

[0031] a. Analytical pure PbF 2 and H 3 BO 3 Mix at a molar ratio of 1:3, then dissolve in 0.6mol / L hydrofluoric acid, and keep stirring to make a suspension A with a Pb ion concentration of 1mol / L;

[0032] b. Add the mineralizer LiF into distilled water, and keep stirring to prepare a transparent solution B with a Li ion concentration of 0.5mol / L;

[0033]c. Mix and stir the suspension A obtained in step a and the transparent solution B obtained in step b in a molar ratio of Pb:Li=1:3, then use analytically pure LiOH to adjust the pH value of the solution to 11, and stir again for 90 minutes Obtain solution C;

[0034] d. Place the solution C obtained in step c in a hydrothermal reactor, control the filling ratio to 50%, and then put it into a temperature-pressure dual-control microwave hydrothermal reactor, select the temperature control mode, and the temperature control temperature is 170 ° C. The time is 3h, naturally cool to room temperature after the reaction finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com