Method for whole-cell catalysis production of pentanediamine through self-control of pH by virtue of byproduct carbon dioxide

A whole-cell, pentamethylenediamine technology, applied in the biological field, can solve problems such as increasing the dosage of pH regulators, increasing equipment investment, and reducing product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 HPLC method detects lysine and 1,5-pentanediamine

[0067] Take 1mL of the whole cell catalytic solution, centrifuge at 8000g for 5min, collect the supernatant to detect the lysine content; take 10μL of the supernatant in a 2mL centrifuge tube, add 200μL of 0.5M NaHCO 3 Aqueous solution and 100 μL of 1% (volume ratio) 2,4-dinitrofluorobenzene acetonitrile solution were heated in the dark at 60°C in a water bath for 60 minutes at a constant temperature, then cooled to room temperature, and 700 μL of 0.04mol / L KH was added 2 PO 4 Dilute the aqueous solution (pH=7.2±0.05, adjust the pH with 40g / L KOH aqueous solution) and shake well, let it stand for 15min and filter before injecting, the injection volume is 15μL;

[0068] The chromatographic column used is a C18 column (ZORBAX Eclipse XDB-C18, 4.6*150mm, Agilent, USA); column temperature: 40°C; UV detection wavelength: 360nm; mobile phase A is 0.04mol / L KH 2 PO 4 Aqueous solution (pH=7.2±0.05, adjust pH wi...

Embodiment 2

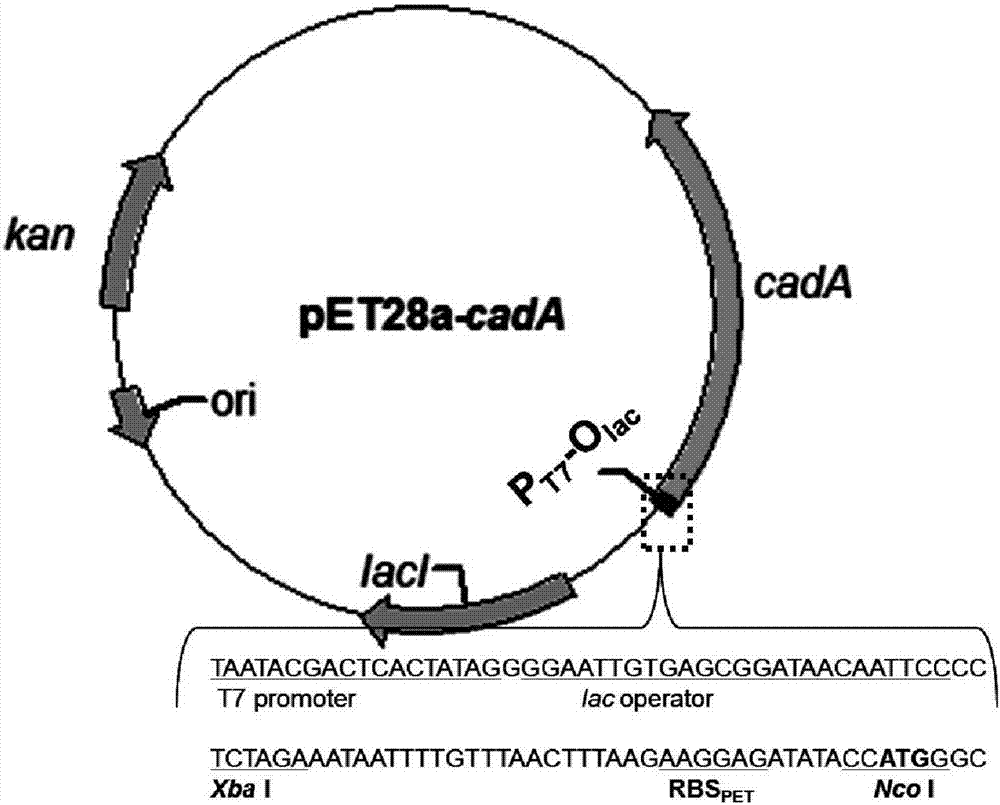

[0074] Example 2 Construction of Whole Cell Catalytic Production of Pentadiamine Engineering Bacteria

[0075] (1) Construction of lysine decarboxylase gene cadA overexpression plasmid

[0076] The ORF of the optimized lysine decarboxylase gene cadA was inserted behind the T7 promoter and RBS of the pET28a(+) expression vector. Primers were designed with optimally designed sequences, using the genomic DNA of wild-type Escherichia coli K12 W3110 strain as a template, using the high-fidelity polymerase KAPAHiFi TM HotStar uses P1 and P2 as primers to amplify the cadA gene by PCR. The nucleotide sequence of the gene is shown in SEQ ID NO.1. The PCR program is: denaturation at 98°C for 30 seconds, annealing at 65°C for 15 seconds, extension at 72°C for 150 seconds, and 26 cycles. The mutation site is introduced by primer P1, thereby obtaining a fragment of the modified lysine decarboxylase gene cadA*.

[0077] P1: 5'-CATG CCATGG CAGTTATTGCAATATTGAATCATATGGGAGT-3' (SEQ ID NO. 5...

Embodiment 3

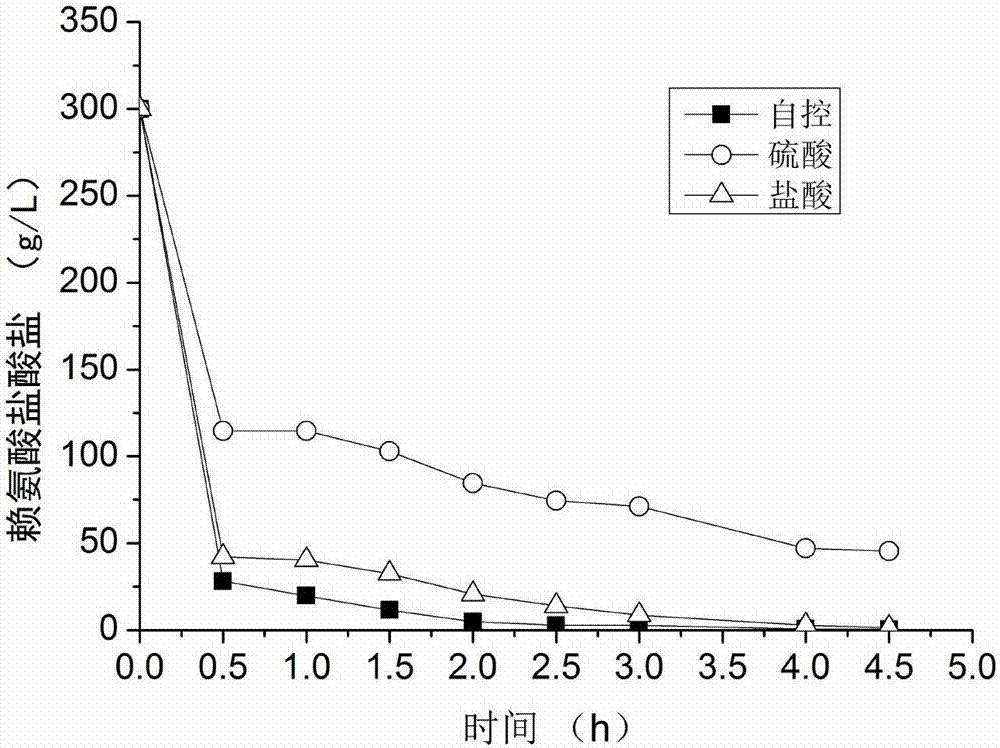

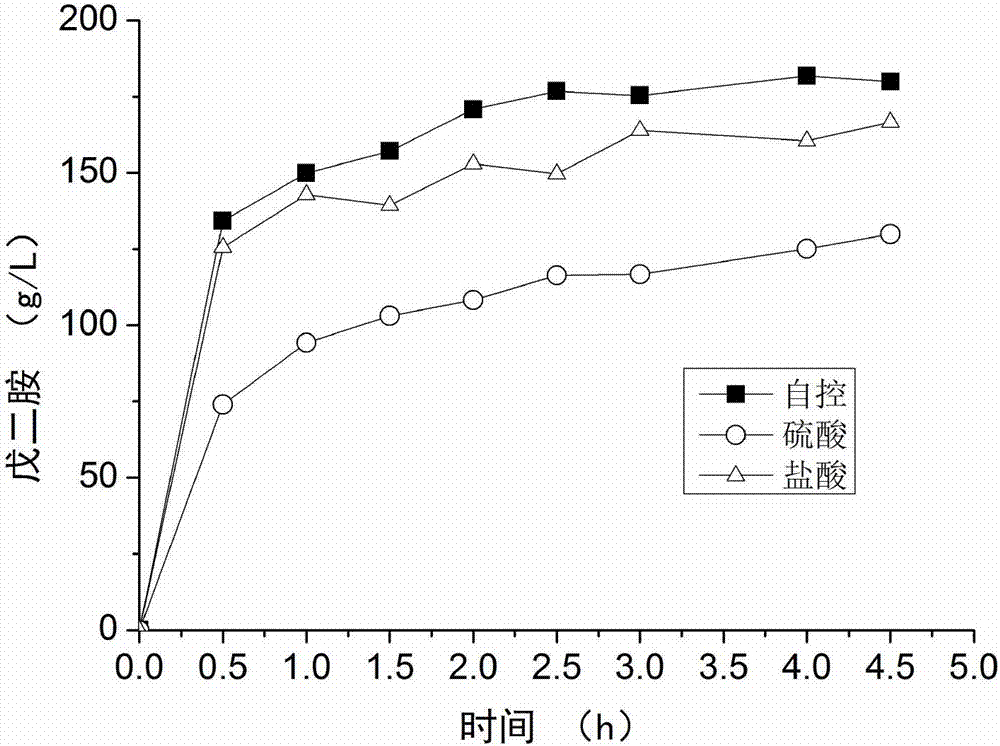

[0096] Example 3 Bacterial Culture and Production Technology Catalyzed by 1,5-Pentanediamine

[0097] Scraping Engineering Bacteria E.coli BL21(DE3)P cadB ::P T7 / pET28a-cadA * The bacterial lawn was inserted into a 500mL Erlenmeyer flask containing 50mL LB (50mg / L kanamycin (5-200mg / L is acceptable) medium), and cultured in a shaker at 37°C and 220rpm for 4h to obtain a seed solution, OD 600 4-5; the seed solution obtained by cultivation is inserted into a 10L fermenter containing 2L inorganic salt medium according to the inoculation amount of 2%, the cultivation temperature is 37°C, the DO is controlled above 30%, and the tank pressure is controlled at 0.02-0.10 MPa. The concentration of glucose in the culture medium was maintained below 5 g / L by feeding the feed solution. When the cell OD in the culture medium 600 When it reaches 30-40, add 0.1mM inducer IPTG, and after 2h, the OD of the bacterial culture solution 600 When the temperature reaches about 80, the wet cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com