Ultrafine glass fiber reinforced HDPE double-wall corrugated pipe

A technology of double-wall corrugated pipe and glass fiber cotton, which is applied in the field of building materials, can solve the problems of poor external pressure resistance, low strength, and low rigidity of pipe rings, etc., and achieve small dimensional shrinkage, high elastic modulus, and smooth surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

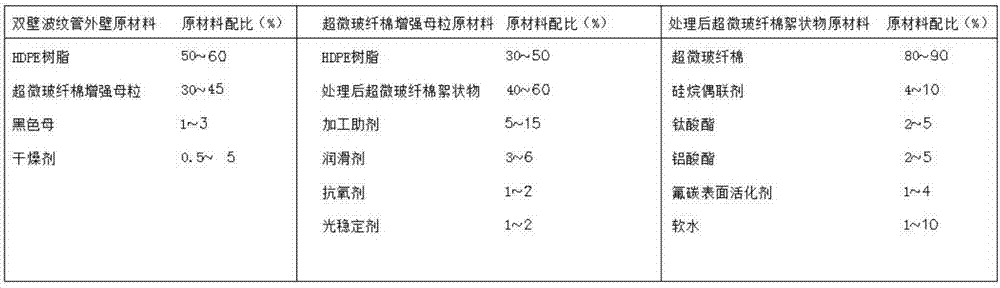

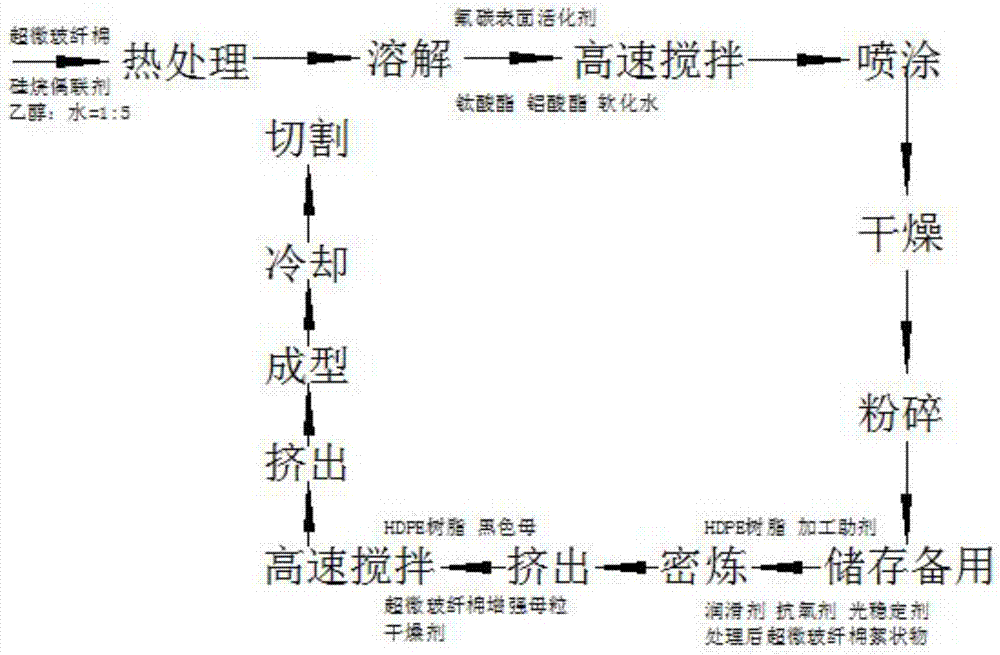

[0025] The outer wall material ratio of HDPE double-wall corrugated pipe: HDPE resin 57%, ultra-fine glass fiber cotton reinforced masterbatch 40%, black masterbatch 1.5% and desiccant 1.5%; the raw material ratio of ultra-fine glass fiber cotton reinforced masterbatch is HDPE 35% of resin, 50% of treated ultrafine glass fiber cotton, 8% of processing aid, 3% of lubricant, 2% of antioxidant and 2% of light stabilizer; treated ultrafine glass fiber cotton includes ultrafine 80% glass fiber cotton, 8% silane coupling agent, 2% titanate, 2% aluminate, 2% fluorocarbon surfactant, 2% soft water.

[0026] Among them, the silane coupling agent is vinyltriethoxysilane; the processing aid is methyl methacrylate polymer; the lubricant is stearic acid or its esters; the antioxidant is hindered phenolic antioxidant; The stabilizer is a benzotriazole ultraviolet absorber.

Embodiment 2

[0028] The outer wall material ratio of HDPE double-wall corrugated pipe: HDPE resin 52%, ultra-fine glass fiber cotton reinforced masterbatch 45%, black masterbatch 2% and desiccant 1%; the raw material ratio of ultra-fine glass fiber cotton reinforced masterbatch is HDPE 40% of resin, 42% of processed ultrafine glass fiber cotton, 9% of processing aid, 5% of lubricant, 2% of antioxidant and 2% of light stabilizer; treated ultrafine glass fiber cotton includes ultrafine Glass fiber cotton 85%, silane coupling agent 5%, titanate 2%, aluminate 2%, fluorocarbon surfactant 1%, soft water 2%.

[0029] Among them, the silane coupling agent is γ-aminopropyltriethylaminosilane; the processing aids are POE, PE-g-MAH and EVA in a ratio of 1:1:1; the lubricants are PE wax, OPE wax and fee The wax, the ratio is 1:1:1; the antioxidant is hindered amine antioxidant; the light stabilizer is benzotriazole ultraviolet absorber.

Embodiment 3

[0031] The outer wall material ratio of HDPE double-wall corrugated pipe: HDPE resin 60%, ultra-fine glass fiber cotton reinforced masterbatch 36.5%, black masterbatch 2% and desiccant 1.5%; the raw material ratio of ultra-fine glass fiber cotton reinforced masterbatch is HDPE 30% of resin, 55% of treated ultrafine glass fiber cotton, 8% of processing aid, 5% of lubricant, 1% of antioxidant and 1% of light stabilizer; treated ultrafine glass fiber cotton includes ultrafine Glass fiber cotton 85%, silane coupling agent 4%, titanate 2%, aluminate 2%, fluorocarbon surfactant 1%, soft water 3%.

[0032] Among them, the silane coupling agent is γ-(ethylenediamino)propyltrimethoxysilane; the processing aid is LLDPE, LDPE and methyl methacrylate polymer in a ratio of 1:1:2; the lubricant is metal soap compound; the antioxidant is a phosphite antioxidant; the light stabilizer is a benzotriazole ultraviolet absorber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com