Mechanical arm used for machining installing face of aluminum alloy ship spray pump

An installation surface and robotic arm technology, applied in the field of robotic arms, can solve the problems of high cost, low processing accuracy and efficiency, and achieve the effects of shortening construction period, improving processing efficiency, and reducing technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the concept, specific structure and technical effects of the present invention will be clearly and completely described in conjunction with the embodiments and drawings to fully understand the purpose, features and effects of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all of the embodiments. Other embodiments obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention.

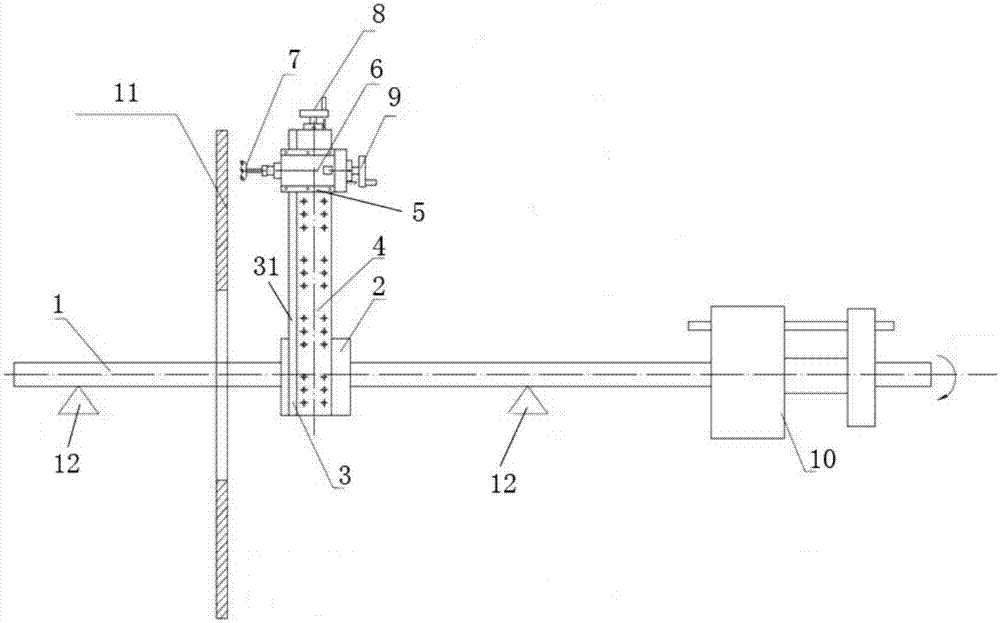

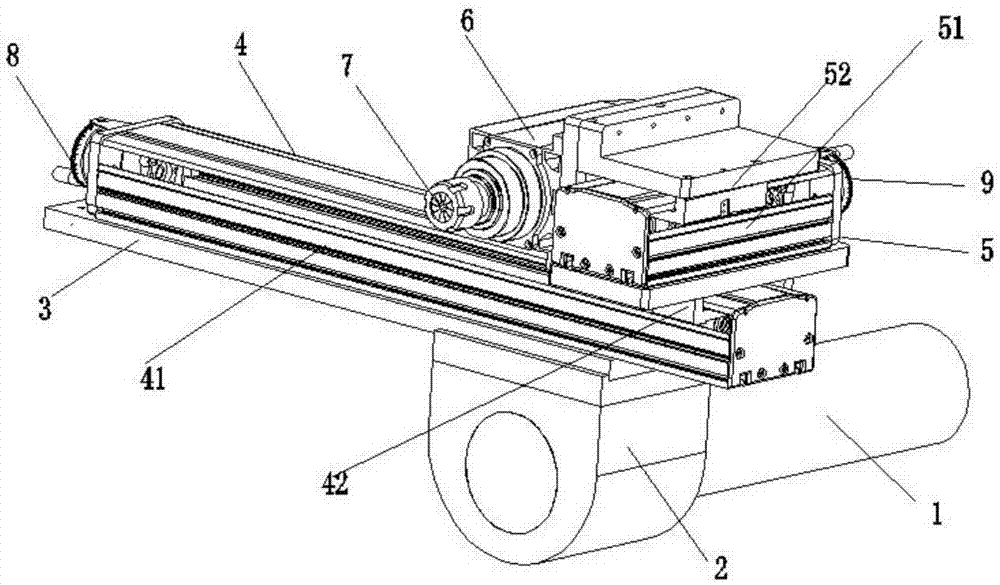

[0019] Reference figure 1 with figure 2 , A mechanical arm for processing the mounting surface of aluminum alloy ship jet pump. The processing object is the mounting surface 11 of aluminum alloy ship jet pump, including boring bar shaft 1, fixed sleeve 2, guide rail seat 3, X-axis guide rail assembly 4 , Y-axis guide rail assembly 5, spindle motor 6 and milling cutter disk 7 installed on the drive shaft of spindle motor 6; among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com