Cobalt-based alloy and cladding layer prepared from the cobalt-based alloy

A technology of cobalt-based alloy and cladding layer, which is applied in metal material coating process, coating, melt spraying and other directions to achieve the effect of refining grain size, improving strength and preventing thermal crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A cobalt-based alloy, comprising cobalt Co, nickel Ni, chromium Cr, iron Fe, silicon Si, tungsten W and carbon C elements, the cobalt-based alloy also includes aluminum Al elements, the specific content of the cobalt-based alloy by weight The chemical composition is: Ni 19wt%, Cr 18wt%, Al8.5wt%, Fe 1.1wt%, Si 1.0wt%, W 4.4wt%, C 0.9wt%, the balance is Co and less than 0.1wt% unavoidable Impurities; the mass percentage of Ni and Co is about 0.40; the mass percentage of Ni and Al is about 2.24. The cobalt-based alloy is 80-150 μm powder.

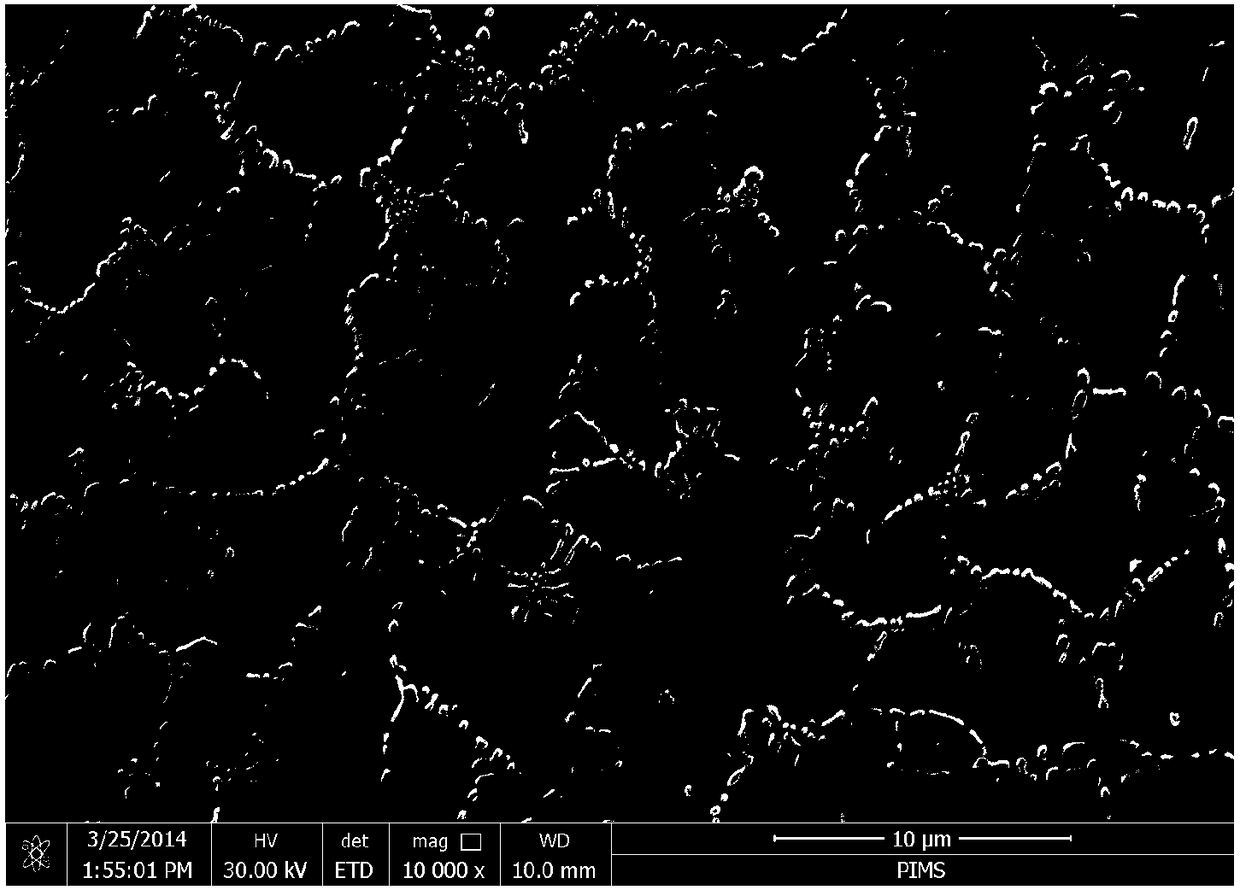

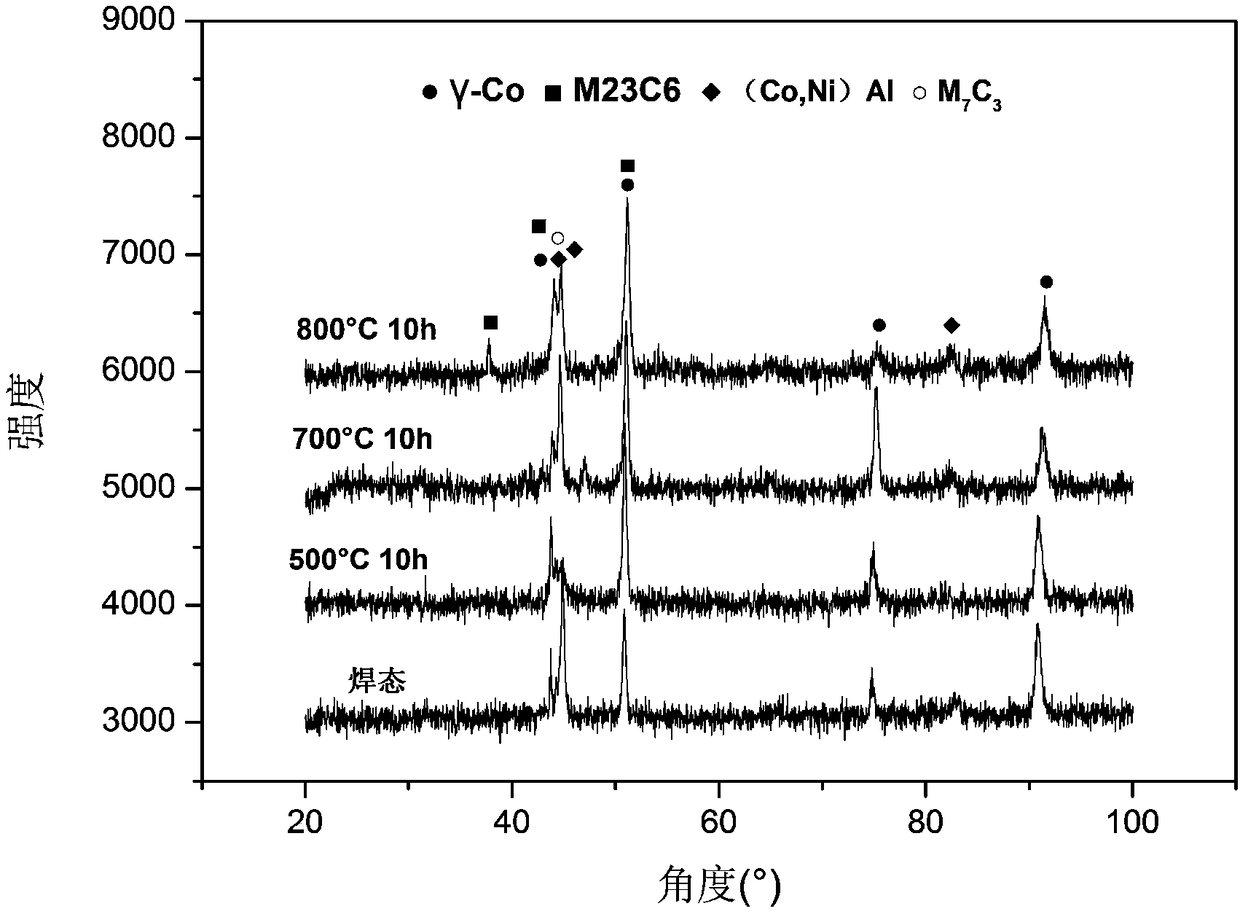

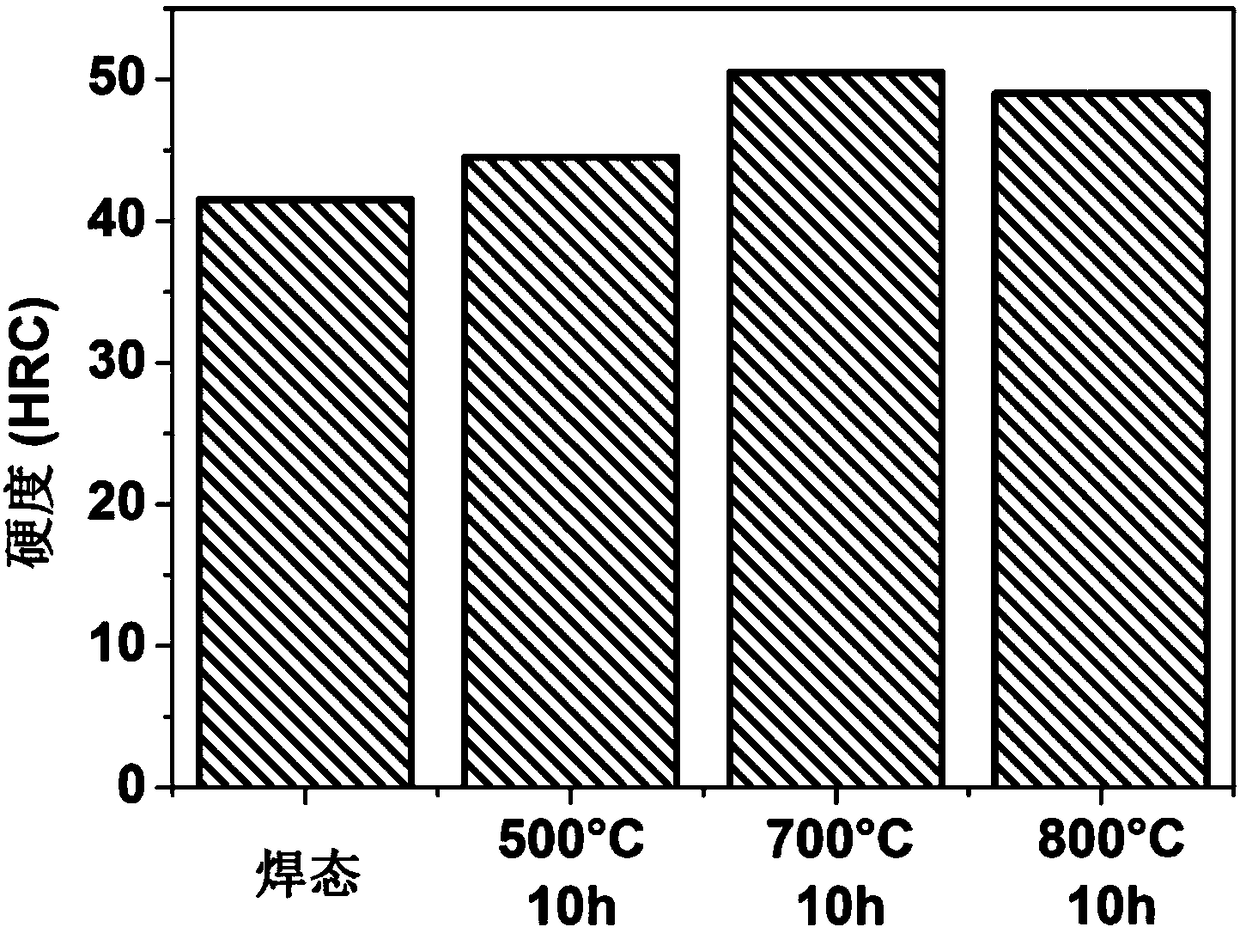

[0051] A cobalt-based alloy cladding layer prepared from the above-mentioned cobalt-based alloy. The cobalt-based alloy cladding layer is prepared by melting the cobalt-based alloy at high temperature and depositing it on the surface of the substrate. In this example, the preparation method is laser cladding , the process parameters used are: laser power 1800W; spot diameter 4mm; laser spot defocus amount 30mm, positive defocus; powde...

Embodiment 2

[0056] A cobalt-based alloy, comprising cobalt Co, nickel Ni, chromium Cr, iron Fe, silicon Si, tungsten W and carbon C elements, the cobalt-based alloy also includes aluminum Al elements, the specific content of the cobalt-based alloy by weight The chemical composition is: Ni 22.5wt%, Cr 19.5wt%, Al10.5wt%, Fe 1.1wt%, Si 1.0wt%, W 4.4wt%, C 0.9wt%, the balance is Co and less than 0.1wt% Impurities to avoid; the mass percent of Ni to Co is about 0.56, and the mass percent of Ni to Al is about 2.14. The cobalt-based alloy is 80-150 μm powder.

[0057] A cobalt-based alloy cladding layer prepared from the above-mentioned cobalt-based alloy. The cobalt-based alloy cladding layer is prepared by melting the cobalt-based alloy at high temperature and depositing it on the surface of the substrate. In this example, the preparation method is laser cladding , the process parameters used are: laser power 1500W; spot diameter 4mm; laser spot defocus amount 30mm, positive defocus; powder ...

Embodiment 3

[0063] A cobalt-based alloy, comprising cobalt Co, nickel Ni, chromium Cr, iron Fe, silicon Si, tungsten W and carbon C elements, the cobalt-based alloy also includes aluminum Al elements, the specific content of the cobalt-based alloy by weight The chemical composition is: Ni 20wt%, Cr 19.5wt%, Al7.5wt%, Fe 1.1wt%, Si 1.0wt%, W 4.4wt%, C 0.9wt%, the balance is Co and less than 0.1wt% unavoidable impurities; the mass percentage of Ni and Co is about 0.44, and the mass percentage of Ni and Al is about 2.67. The cobalt-based alloy is 80-150 μm powder.

[0064] A cobalt-based alloy cladding layer prepared from the above-mentioned cobalt-based alloy. The cobalt-based alloy cladding layer is prepared by melting the cobalt-based alloy at high temperature and depositing it on the surface of the substrate. In this example, the preparation method is laser cladding , the process parameters used are: laser power 2200W; spot diameter 5mm; laser spot defocus amount 40mm, positive defocus;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com