A magnetic field heat treatment furnace with stable performance

A heat treatment furnace and stable technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as magnetic instability of workpieces, and achieve the effects of convenient maintenance or maintenance, uniform heating, and stable magnetic properties of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

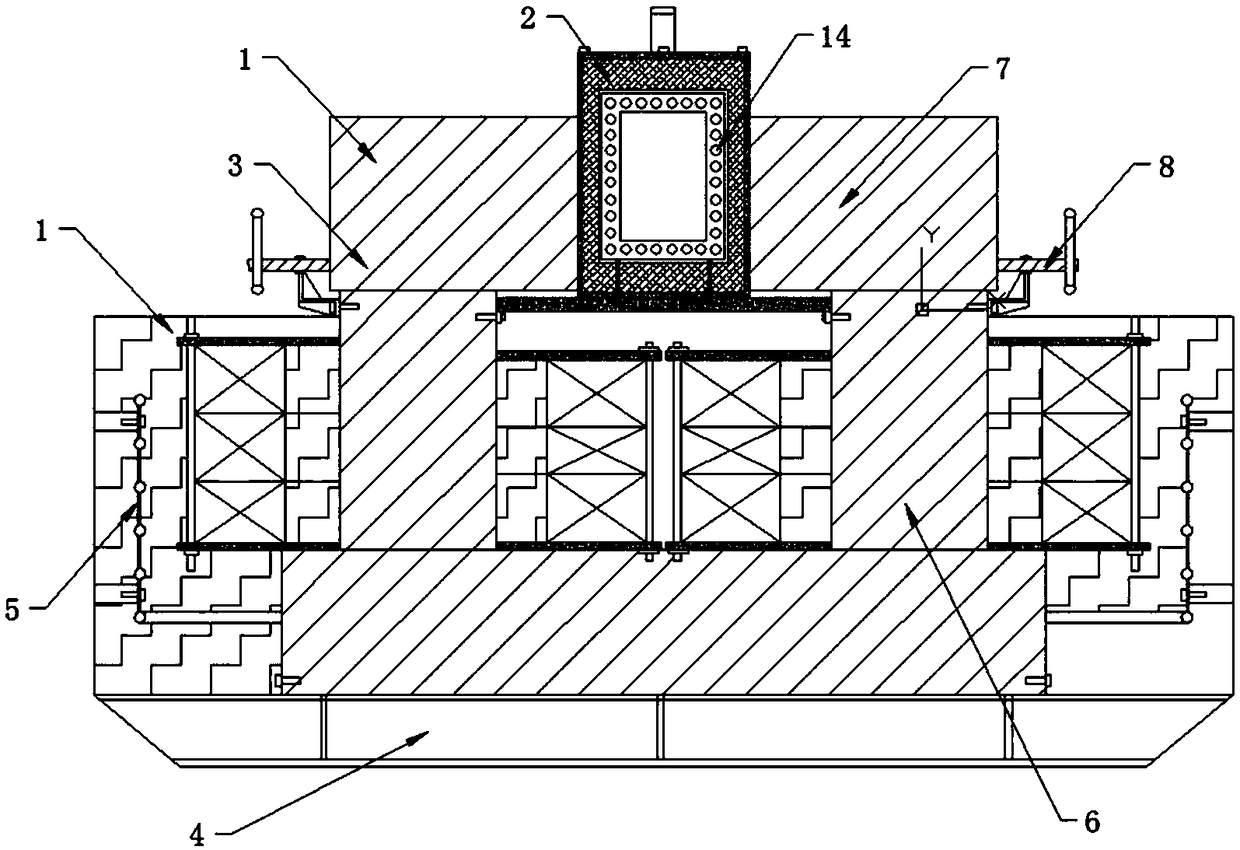

[0026] A magnetic field heat treatment furnace with stable performance is characterized in that it includes a furnace body 1, a heating furnace 2, an electromagnetic system 3, a cooling oil tank 4 and a water cooling circulation system 5; the electromagnetic system 3, the cooling oil tank 4 and the water cooling circulation system 5 are all It is arranged inside the furnace body 1; the cooling oil tank 4 is arranged inside the furnace body 1, and the water cooling circulation system 5 passes through the inside of the cooling oil tank 4 and is connected to the tap water pipe;

[0027] The electromagnetic system 3 includes a lower magnetic pole 6 arranged in the cooling oil tank 4 and two opposite upper magnetic poles 7 movably connected to the upper part of the furnace body 1; the heating furnace 2 is movably arranged between the two upper magnetic poles 7; The upper part of the furnace body 1 is located outside the ends of the two upper magnetic poles 7, and is respectively pro...

Embodiment 2

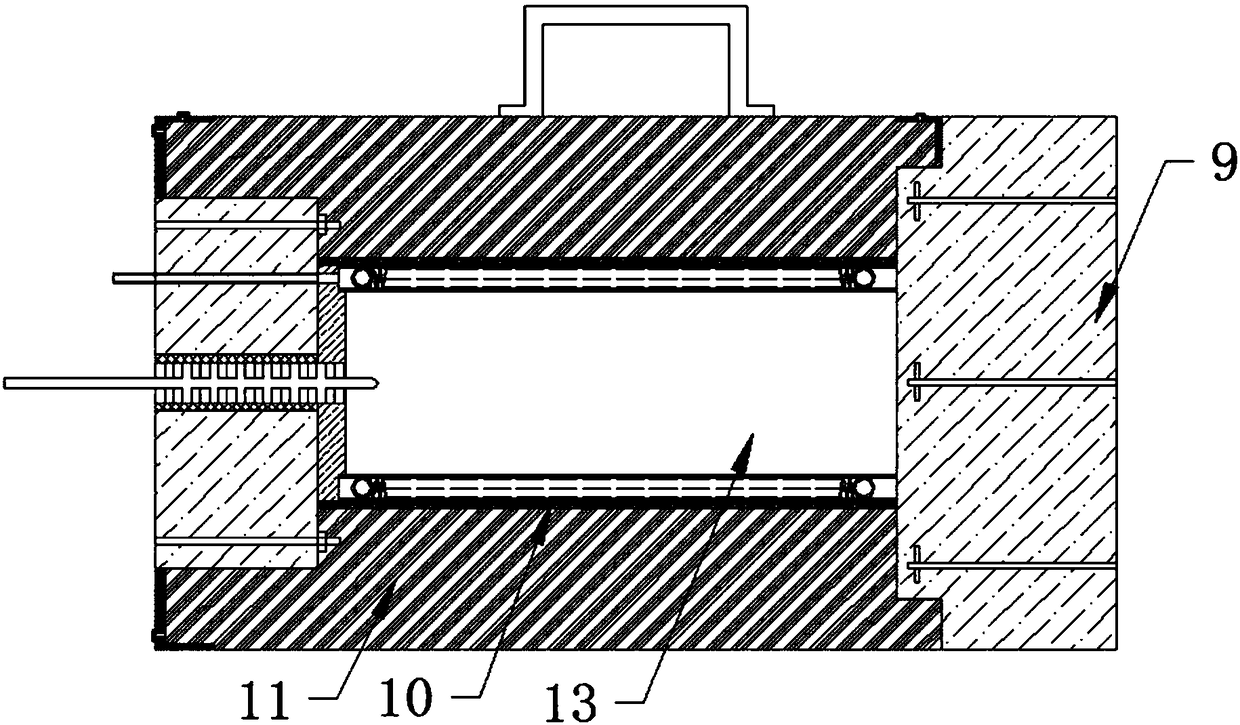

[0030] This embodiment is further optimized based on Embodiment 1. The heating element is a Φ2.0mm resistance wire drawn by high-temperature electrothermal material Cr20Ni80 and made into a spiral structure with a middle diameter of 11mm, a spiral pitch of 4.0mm, and a total number of turns of 2106.5 turns , the heating element can make the workpiece to be magnetized be heated more uniformly in the heating furnace, so that the magnetism of the processed workpiece is more stable.

Embodiment 3

[0032] This embodiment is further optimized based on Embodiment 1. Before the high-alumina aluminum silicate fibers of the furnace lining 11 are manufactured and assembled, they are cured to ensure that the furnace lining 11 does not shrink during use, increase the stability of the furnace lining 11, and increase the service life. , Reduce maintenance costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com