Preparation method of high-capacity lithium titanate material

A lithium titanate, high-capacity technology, applied in titanate, alkali metal titanate, chemical instruments and methods, etc., can solve the problems of low battery energy density, limited application of lithium titanate, complicated process, etc. Cost control, easy industrial production application, effect of shortening growth time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

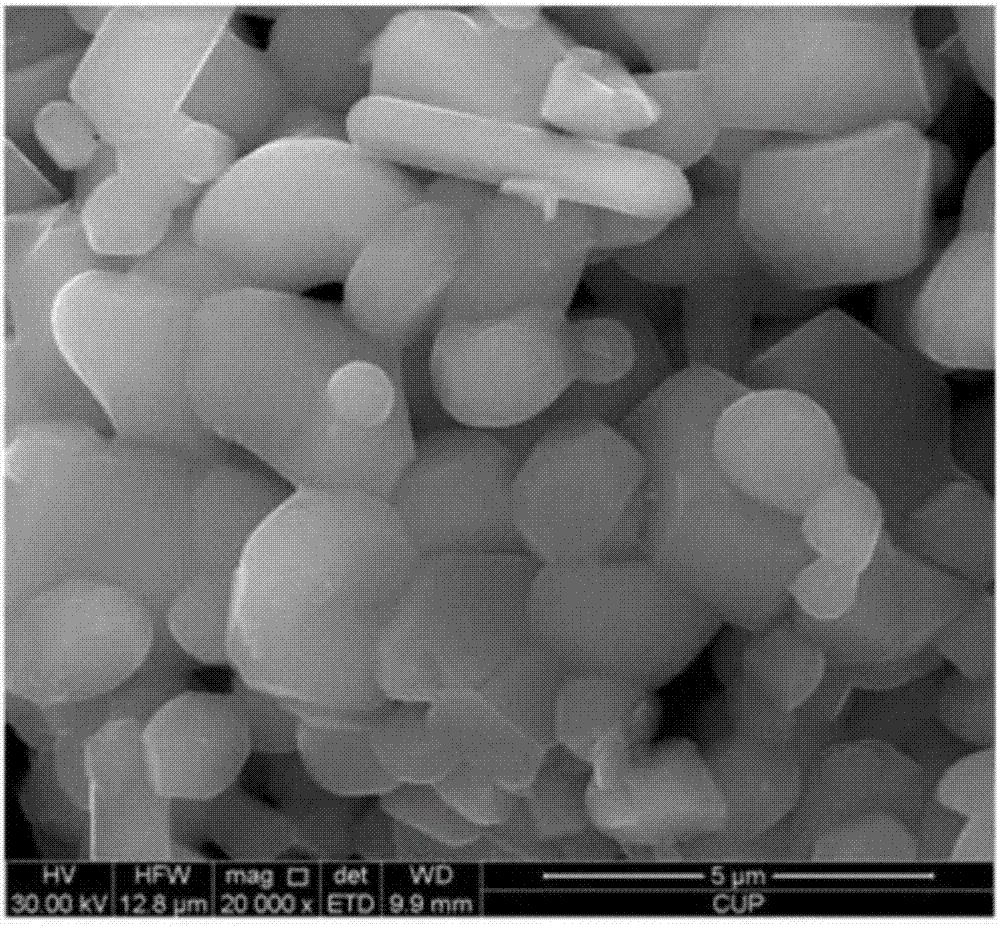

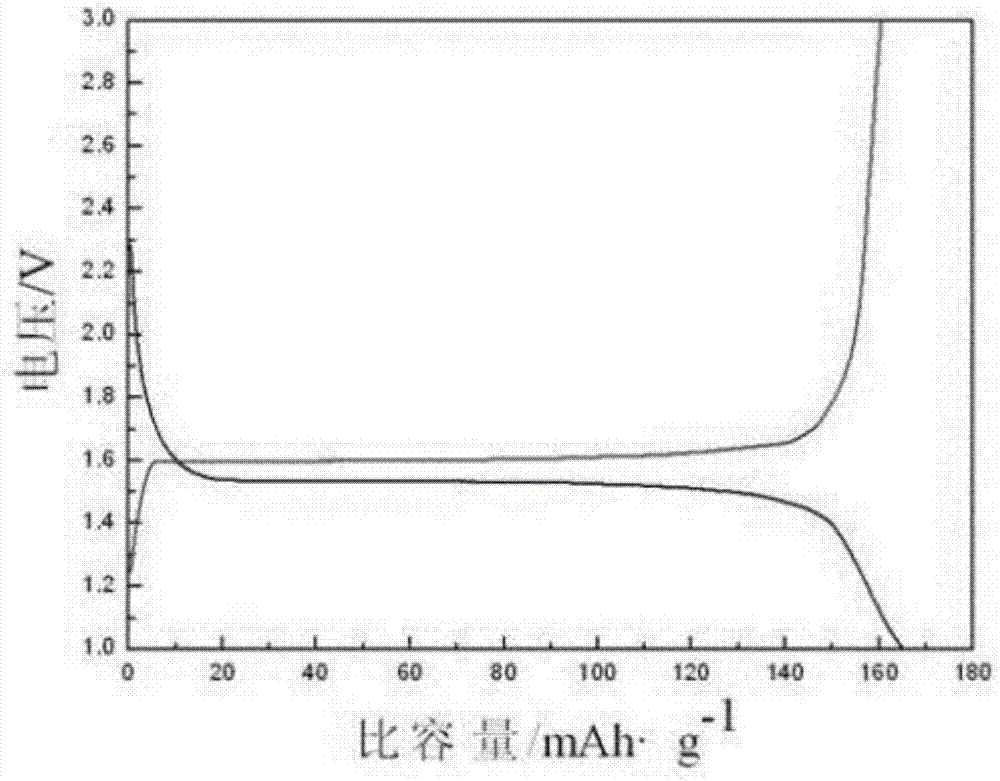

[0021] Lithium carbonate and anatase titanium dioxide are selected as raw materials, lithium fluoride is used as a flux, the ratio of Li / Ti (mol%) is 0.80:1, the content of lithium fluoride is 1wt% of the mass of TiO2, and ethanol is used as a dispersant , ethanol: solid powder (wt%) = 0.7:1, after ball milling on a ball mill for 6 hours, dry in an oven with 21.6% oxygen gas at 40°C to obtain a precursor. Treat the precursor at 500°C for 2 hours in an atmosphere with an oxygen content of 10%, then heat it up to 800°C after cooling, keep it in an atmosphere with an oxygen content of 21.6% for 8 hours, and finally lower it to room temperature to obtain Li4Ti5O12 sample. The particle size of the obtained material is uniform, and the tap density is 1.20g / cm3. Compared with the tap density (0.78g / cm3) of lithium titanate prepared under the same conditions without adding flux, the density is significantly improved. A button battery was prepared with a lithium metal sheet as the cou...

Embodiment 2

[0023] Lithium nitrate and rutile titanium dioxide are selected as raw materials, boric acid is used as a flux, and the ratio of Li / Ti (mol%) is 0.82:1, and the content of boric acid is 0.5wt% of the mass of TiO2. Ethanol is used as a dispersant, ethanol: solid Powder (wt%)=0.8:1 After ball milling on a ball mill for 6 hours, the precursor was dried at 60° C. by passing a gas containing 0.1% oxygen in an oven. Treat the precursor at 500°C for 2 hours in an atmosphere with an oxygen content of 0.01%, then heat it up to 800°C for 8 hours in an atmosphere with an oxygen content of 99% after cooling, and finally get a Li4Ti5O12 sample after cooling down to room temperature . The obtained material particles are smooth and uniform in size, and the tap density is 1.36g / cm3, which is significantly higher than the tap density (0.80g / cm3) of lithium titanate prepared under the same conditions without adding flux. A button battery was prepared with metal lithium sheet as the counter ele...

Embodiment 3

[0025] Lithium hydroxide and anatase titanium dioxide are selected as raw materials, lithium tetraborate is used as a flux, and the ratio of Li / Ti (mol%) is 0.84: the content of lithium tetraborate is 0.5wt% of the mass of TiO2 for batching, and methanol is used as a dispersant , Methanol: solid powder (wt%) = 1: 1. After ball milling on a ball mill for 6 hours, the precursor was dried in an oven with 21.6% oxygen-containing gas at 50°C. Treat the precursor at 500°C for 2 hours in an atmosphere with an oxygen content of 21.6%, then heat it up to 800°C for 8 hours in an atmosphere with an oxygen content of 0.1% after cooling, and finally lower it to room temperature to obtain Li4Ti5O12 sample. The obtained material particles are smooth and uniform in size, and the tap density is 1.48g / cm3, which is significantly higher than the tap density (0.82g / cm3) of lithium titanate prepared under the same conditions without adding flux. A button battery was prepared with a metal lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com