A kind of carbon/calcium aluminate composite powder and preparation method thereof

A technology of calcium aluminate and composite powder, applied in the preparation of calcium aluminate, alkaline earth metal aluminate/alumina/aluminum hydroxide, carbon compounds, etc., can solve the problem of limiting the application of carbon-containing castables, affecting the service life of materials, Easy to be oxidized and other problems, to achieve the effect of reducing production cost, reducing energy consumption, improving dispersibility and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the carbon / calcium aluminate composite powder comprises taking organic acid calcium, calcium peroxide, aluminum powder and alumina as raw materials, and adopting a self-propagating high-temperature synthesis method to prepare the carbon / calcium aluminate composite powder. The calcium organic acid is one of calcium oxalate, calcium gluconate, calcium citrate and calcium stearate.

[0037] In terms of mass percentage, the calcium organic acid in the raw material is 1.6% to 16%, the calcium peroxide in the raw material is 30% to 38%, the aluminum powder in the raw material is 9% to 15%, and the alumina in the raw material is 42% to 50%. , the above-mentioned raw materials are integrated into 100%.

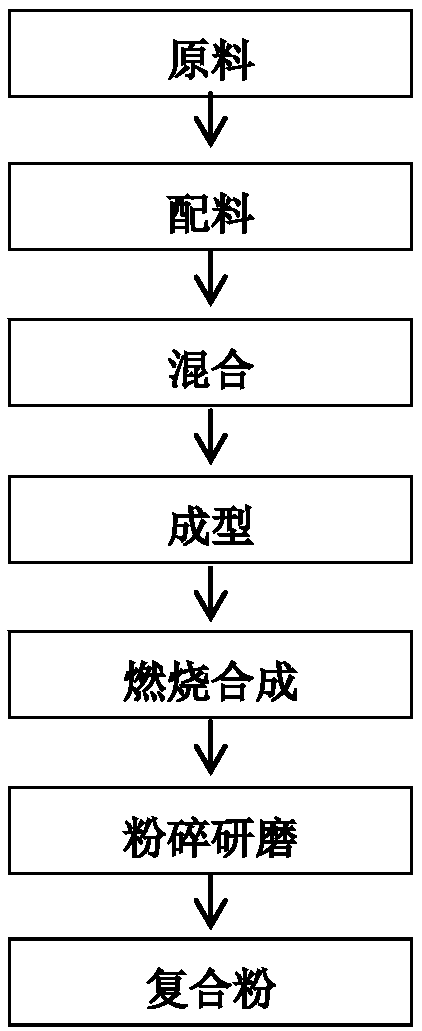

[0038] Specifically, combine figure 1 , the self-propagating high-temperature synthesis method of the present invention comprises organic acid calcium, calcium peroxide, aluminum powder and aluminum oxide by CaO-Al 2 o 3 The phase diagram is used fo...

Embodiment 1

[0044]This embodiment adopts calcium peroxide powder (purity ≥ 99.0%), calcium oxalate powder (purity ≥ 99.0%), aluminum powder (purity ≥ 99.0%) and alumina powder (purity ≥ 99.0%) as raw materials, calculated by mass percentage , calcium peroxide powder (purity ≥ 99.0%) is 30.59%, calcium oxalate powder (purity ≥ 99.0%) is 13.60%, aluminum powder (purity ≥ 99.8%) is 13.38%, alumina (purity ≥ 99.0%) is 42.43 %. Put the uniformly mixed raw materials into the crucible, and then lightly press them into shape. After the molding is completed, put the sample into the self-propagating high-temperature reaction furnace, place C-Ti igniter on the sample, and self-propagating high-temperature synthesis The reaction is initiated by the heat generated by the C-Ti reaction placed on the top of the sample, while the C and Ti reactions are initiated by a tungsten wire.

[0045] Under the conditions of vacuuming (vacuum degree is -0.092MP) and argon filling, the sample is ignited and ignited...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is: by mass percentage, calcium peroxide powder (purity ≥ 99.0%) is 35.40%, calcium oxalate powder (purity ≥ 99.0%) is 15.72%, aluminum powder (purity ≥ 99.8%) ) was 15.47%, and alumina (purity ≥ 99.0%) was 33.41%; finally, a carbon / calcium aluminate composite powder with a particle size ≥ 200 meshes was obtained.

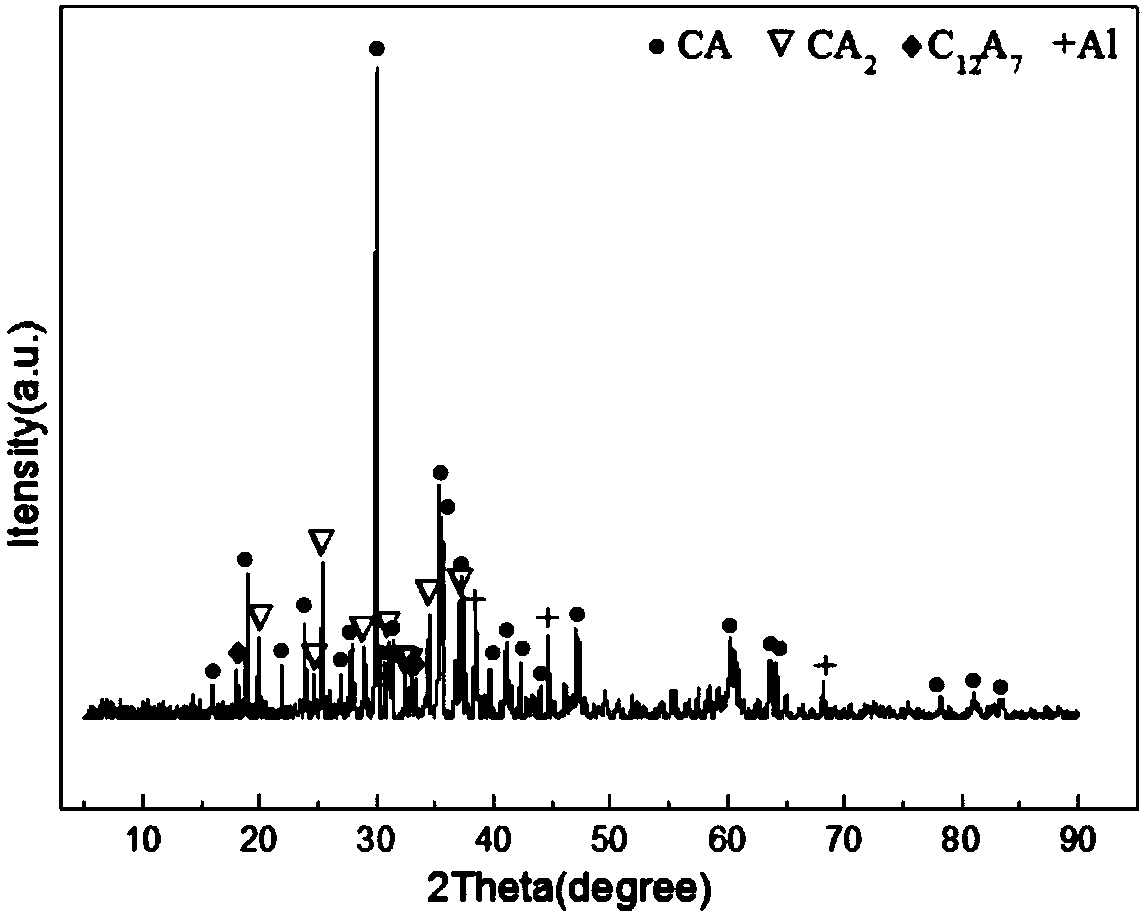

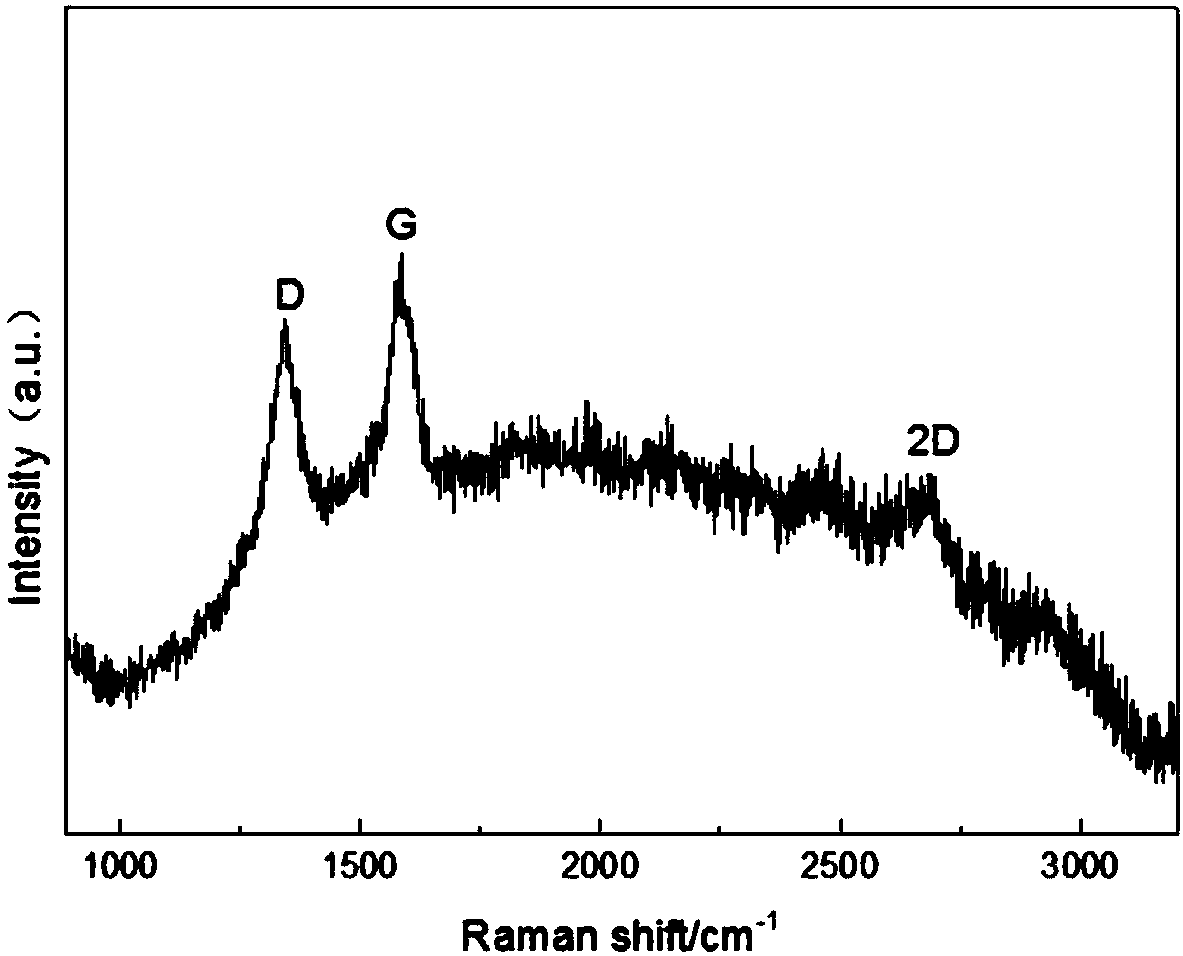

[0049] Carry out X-ray diffraction analysis and Raman spectrum analysis to the carbon / calcium aluminate composite powder prepared in embodiment 2, see Figure 4 and 5 . in Figure 5 Show 1353cm -1 D peak of disordered carbon structure appears, 1586cm -1 G peak of graphitized structure appears, 2707cm -1 2D peaks of multilayer graphene appear. Explain that the elemental carbon in the carbon / calcium aluminate composite powder prepared in Example 2 is a mixture of various structural forms containing carbon, and the actual carbon element content is 1.61% as measured by a high-frequency infrared carbon-su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com