Polysiloxane composition laminated board and metal foil-coated laminated board thereof

A technology of polysiloxane and composition, applied in the field of laminates, can solve the problems of poor adhesion between pure silicone composition and copper foil, and achieve excellent electrical insulation performance, high feasibility of preparation process, and high peel strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

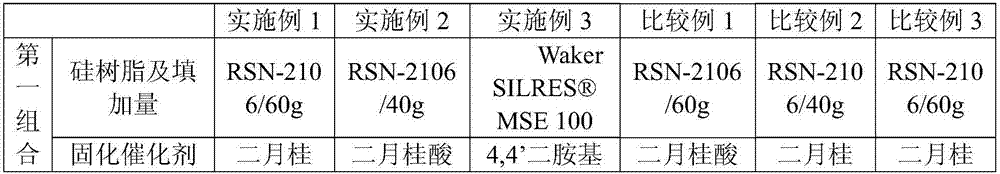

Embodiment 1

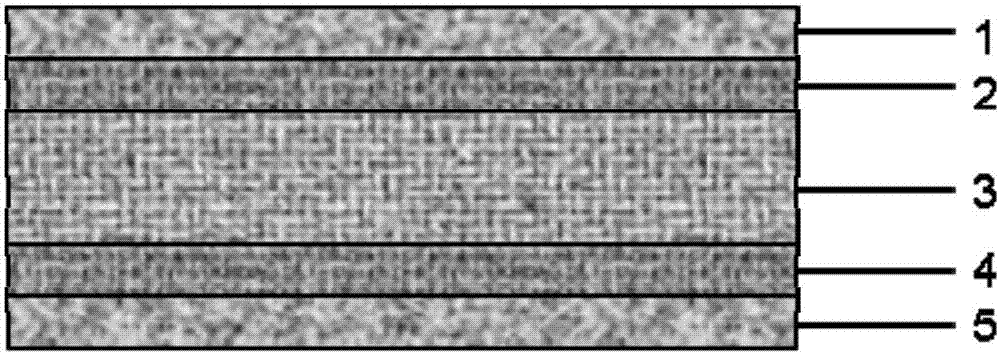

[0048] The first polysiloxane layer composition and the third polysiloxane layer composition are made into resin glue, which is directly bonded to the rough surface of the copper foil by coating, and then heated in the range of 120°C-180°C Internal heating for 3-15 minutes, so that the polysiloxane composition reaches a semi-cured state, ready for use; the second polysiloxane layer composition is impregnated on the glass fiber cloth, and baked in the range of 120°C-190°C for 3- 15 minutes, control the reaction progress of hydrosiloxanation at 30%-70%, record it as the second P sheet, and reserve it; Cover the copper foil coated with the first and third polysiloxane layer compositions, and vacuum press in the range of 190°C-220°C to obtain the polysiloxane-based coating with good peel strength. copper plate.

Embodiment 2

[0050] Immerse the first and third polysiloxane layer compositions on the glass fiber cloth, and then bake in the range of 120°C-180°C for 3-15min, so that the polysiloxane composition reaches half In the cured state, a prepreg is formed, recorded as the first P sheet, and reserved. The composition of the second polysiloxane layer is impregnated on the glass fiber cloth, baked in the range of 120°C-190°C for 3-15min, and the reaction progress of hydrosiloxanation is controlled at 30%-70%, recorded as the second Two P sheets, spare; according to the thickness requirements of the copper-clad laminate, stack several second P sheets, and stack one or two first P sheets on the upper and lower sides, and copper foil on the upper and lower sides. Vacuum pressing within the range of 190° C. to 220° C. to prepare the polysiloxane-based copper-clad laminate with better peel strength.

Embodiment 3

[0052] The first composition layer and the third composition layer use different condensation type silicone resins from Example 2, catalysts, fillers, and silane coupling agents, and the second composition layer uses different silicone resins and catalysts from Example 2. , addition polymerization inhibitor, preparation method and technology are all identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com