A method for preparing an anode porous copper current collector used for a lithium metal battery

A lithium metal battery and porous copper technology, applied in battery electrodes, lithium batteries, electrode carriers/collectors, etc., can solve the problems of inconvenient operation and high preparation cost, achieve convenient operation, low cost, and improve comprehensive electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

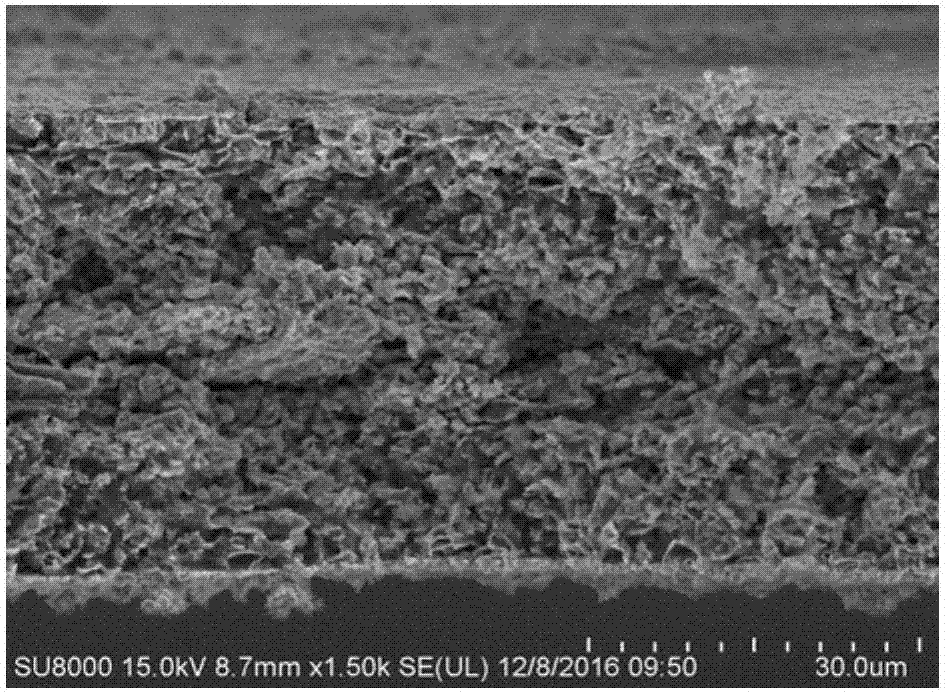

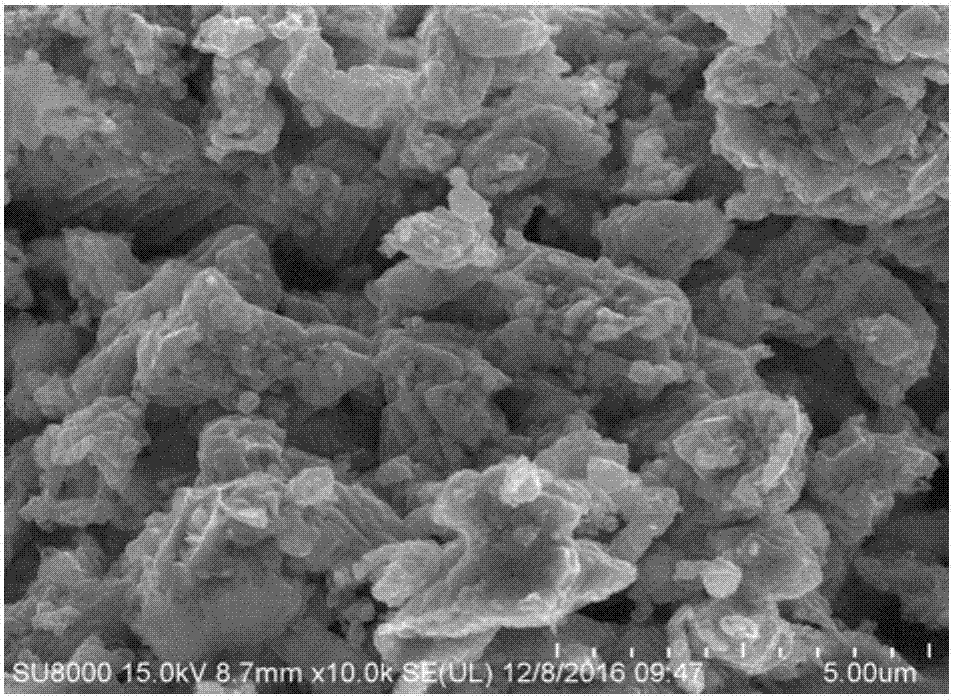

[0033] This embodiment provides a method for preparing a negative electrode porous copper current collector for a lithium metal battery, which at least includes the following steps:

[0034] In the first step, the surface of the Cu-Zn alloy sheet is cleaned with ethanol to remove impurities (such as esters) on the surface of the Cu-Zn alloy sheet. In the Cu-Zn alloy sheet, the atomic mass ratio of Cu is 60%;

[0035] Second step, preparation concentration is the hydrochloric acid solution of 0.5mol / L;

[0036] The third step is to use a three-electrode system on the electrochemical workstation, use platinum as the counter electrode, a saturated calomel electrode as the reference electrode, a Cu-Zn alloy sheet as the working electrode, and use the hydrochloric acid solution obtained in the second step as the electrolyte , using linear scan cyclic voltammetry from -1V to 0.5V cut-off voltage, scan 30 circles, the scan speed is 1mV / s, based on the quality of Cu-Zn alloy sheet, th...

Embodiment 2

[0039] This embodiment provides a method for preparing a negative electrode porous copper current collector for a lithium metal battery, which at least includes the following steps:

[0040] In the first step, the surface of the Cu-Mn alloy sheet is cleaned with methanol to remove impurities (such as esters) on the surface of the Cu-Mn alloy sheet. In the Cu-Mn alloy sheet, the atomic mass ratio of Cu is 70%;

[0041] The second step, preparation concentration is the sulfuric acid solution of 0.3mol / L;

[0042]The third step is to use a three-electrode system on the electrochemical workstation, using nickel as the counter electrode, saturated calomel electrode as the reference electrode, Cu-Mn alloy sheet as the working electrode, and the sulfuric acid solution obtained in the second step as the electrolyte , using linear sweep cyclic voltammetry from -1V to 0.7V cut-off voltage, scanning 40 circles, taking the quality of the Cu-Mn alloy sheet as the benchmark, and the precipi...

Embodiment 3

[0044] This embodiment provides a method for preparing a negative electrode porous copper current collector for a lithium metal battery, which at least includes the following steps:

[0045] In the first step, the surface of the Cu-Al alloy sheet is cleaned with acetone to remove impurities (such as esters) on the surface of the Cu-Al alloy sheet. In the Cu-Al alloy sheet, the atomic mass ratio of Cu is 50%;

[0046] Second step, preparation concentration is the hydrochloric acid solution of 0.7mol / L;

[0047] The third step is to use a three-electrode system on the electrochemical workstation, use platinum as the counter electrode, a saturated calomel electrode as the reference electrode, a Cu-Al alloy sheet as the working electrode, and use the hydrochloric acid solution obtained in the second step as the electrolyte , using linear sweep cyclic voltammetry from -1V to -0.2V cut-off voltage, scanning 20 circles, taking the quality of the Cu-Al alloy sheet as the benchmark, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com