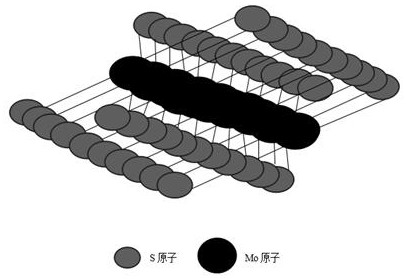

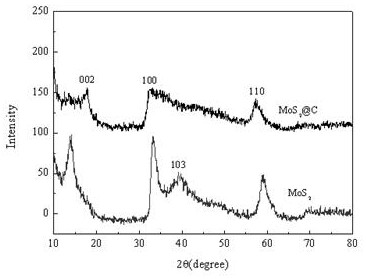

MoS2@C composite anode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of volume expansion structure collapse, poor electrochemical performance, poor electrical conductivity, etc., to achieve good retention, good electricity Chemical properties, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

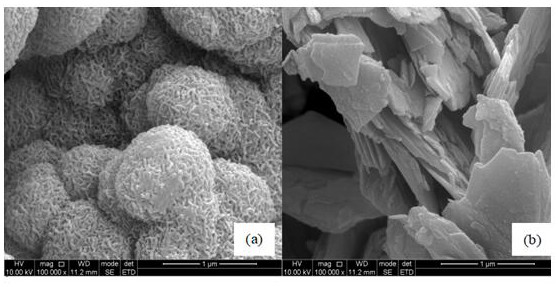

Embodiment 1

[0032] 1) Accurately weigh 0.8g of glucose and dissolve it in 30mL of deionized water, then add 10mL of 0.5% surfactant (hexadecyltrimethylammonium bromide), and ultrasonically disperse for 30min to obtain a uniform solution.

[0033]2) Weigh 0.726g of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 1.198g thiourea (NH 2 CSNH 2 ), sequentially added to the homogeneous solution in step 1), stirred vigorously for 3 hours, then transferred the supernatant liquid to a 50mL stainless steel reactor with polytetrafluoroethylene liner, and placed it in an oven at 180°C for hydrothermal reaction for 10 hours , cooled to room temperature, after the reaction, the hydrothermal reaction product was centrifuged at 10,000 rad / min for 10 min to obtain a black product.

[0034] 3) After the black product obtained in step 2) was washed alternately with deionized water and absolute ethanol for 3 times, it was dried in a vacuum oven at 80°C for 12 hours, and then transferred to a tube furn...

Embodiment 2

[0036] 1) Accurately weigh 0.5g of glucose and dissolve it in 30mL of deionized water, then add 10mL of 0.5% surfactant (hexadecyltrimethylammonium bromide), and ultrasonically disperse for 30min to obtain a uniform solution.

[0037] 2) Weigh 0.484g of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 0.456g thiourea (NH 2 CSNH 2 ), sequentially added to the homogeneous solution in step 1), stirred vigorously for 3 hours, then transferred the supernatant liquid to a 50mL stainless steel reactor with polytetrafluoroethylene liner, and placed it in an oven at 200°C for hydrothermal reaction for 15 hours , cooled to room temperature, after the reaction, the hydrothermal reaction product was centrifuged at 8000 rad / min for 15 min to obtain a black product.

[0038] 3) After the black product obtained in step 2) was washed alternately with deionized water and absolute ethanol for 3 times, it was dried in a vacuum oven at 60°C for 8 hours, and then transferred to a tube furnac...

Embodiment 3

[0040] 1) Accurately weigh 0.5g of glucose and dissolve it in 30mL of deionized water, then add 10mL of 0.8% surfactant (sodium dodecylsulfonate), and ultrasonically disperse for 30min to obtain a uniform solution.

[0041] 2) Weigh 0.242g of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and 0.76g thiourea (NH 2 CSNH 2 ), sequentially added to the homogeneous solution in step 1), stirred vigorously for 3 hours, then transferred the supernatant liquid to a 50mL stainless steel reactor with polytetrafluoroethylene liner, and placed it in an oven at 220°C for hydrothermal reaction for 20 hours , cooled to room temperature, after the reaction, the hydrothermal reaction product was centrifuged at 9000 rad / min for 12.5 min to obtain a black product.

[0042] 3) After the black product obtained in step 2) was washed alternately with deionized water and absolute ethanol for 3 times, it was dried in a vacuum oven at 70°C for 10 hours, and then transferred to a tube furnace at 600°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com