Copper oxide pillared layered manganese oxide catalyst as well as preparation method and application thereof

A technology of layered manganese oxide and copper oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve catalyst chlorine poisoning, high price, resource Shortage and other problems, to achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) 140g potassium hydroxide is dissolved in 300ml distilled water; (2) 40g manganese acetate tetrahydrate and 3g copper chloride are dissolved in 300ml distilled water; (3) the solution of step (2) is added to step (1) solution, accompanied by stirring; (4) 9.5g potassium permanganate was dissolved in 1L distilled water and added to the suspension obtained in step (3) with stirring; (5) step (4) obtained The suspension was stirred at room temperature for 72 hours; (6) the suspension in step (5) was filtered, washed with 1mol / L hydrochloric acid and distilled water several times, and then dried in a 65°C oven for 16 hours; (7) The sample prepared in step (6) was calcined at 300° C. in an air atmosphere for 5 hours, and the heating rate during the heating process was 5° C. / min.

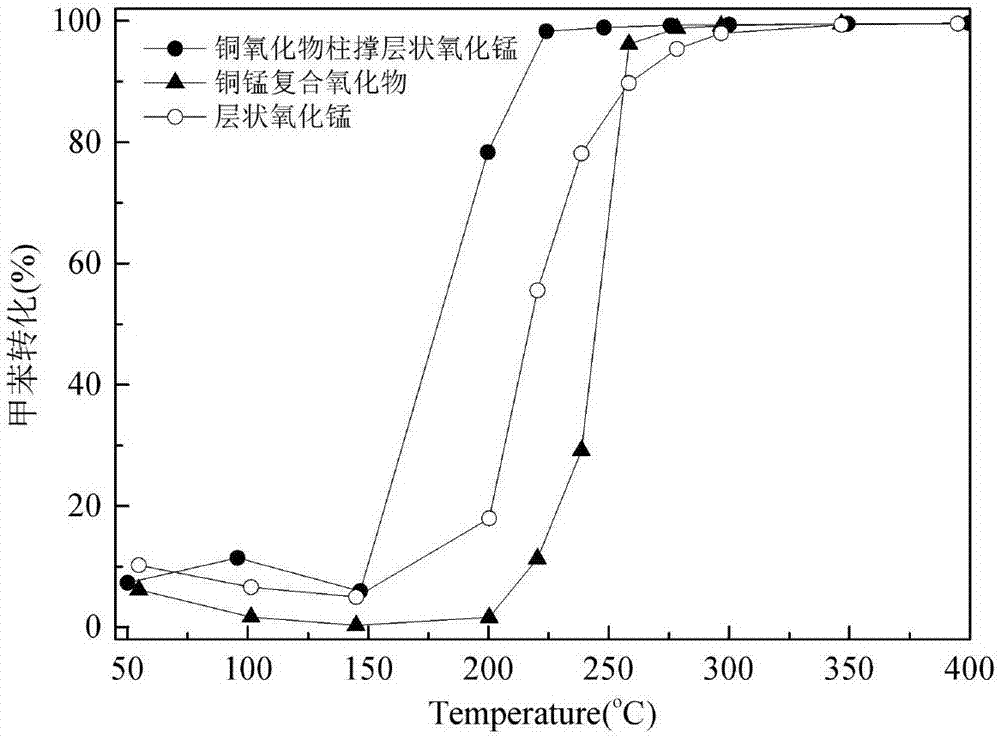

[0035] The present embodiment shows by calculation that the mol ratio of Cu:Mn is 1:9, and the toluene conversion performance test is as follows figure 1 Shown, the light-off temperature of its...

Embodiment 2

[0043] In this example, copper oxide pillared layered manganese oxide catalysts with different copper contents were prepared by changing the amount of copper nitrate added.

[0044] (1) 140g potassium hydroxide is dissolved in 300ml distilled water; (2) 39.2g manganese acetate tetrahydrate and a certain amount of copper nitrate are dissolved in 300ml distilled water, wherein the molar ratio of Cu / Cu+Mn is 0.05-0.5; (3) Add the solution of step (2) to the solution obtained in step (1) with stirring; (4) dissolve 9.5g of potassium permanganate in 1L of distilled water and add it to the suspension obtained in step (3). (5) Place the suspension obtained in step (4) at 60°C with stirring for 72h; (6) Filter the suspension in step (5), and use 1M hydrochloric acid and Rinse with distilled water several times and then dry in an oven at 65°C for 16h; (7) The solid material obtained in step (6) was roasted in air at 300°C for 5h, and the heating rate during the heating process was 5°C / ...

Embodiment 3

[0046] In this example, copper oxide pillared layered manganese oxide catalysts at different calcination temperatures were obtained by changing the calcination temperature.

[0047] (1) 140g potassium hydroxide is dissolved in 300ml distilled water, is placed in ice bath after being cooled to room temperature; (2) 39.2g manganese acetate tetrahydrate and 3g cupric chloride are dissolved in 300ml distilled water; (3) step The solution of (2) is added in the solution that step (1) obtains, and with stirring; (4) after 9.5g potassium permanganate is dissolved in 1L distilled water, join in the suspension that step (3) obtains and with with stirring; (5) place the suspension obtained in step (4) at 40°C with stirring for 72 hours; (6) filter the suspension in step (5), wash it several times with 1M hydrochloric acid and distilled water and then Dry in an oven at 65°C for 16 hours; (7) The solid material obtained in step (6) is roasted in air at 65-500°C for 5 hours, and the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com