Polysaccharide fragment of Dendrobium officinale and extraction method thereof

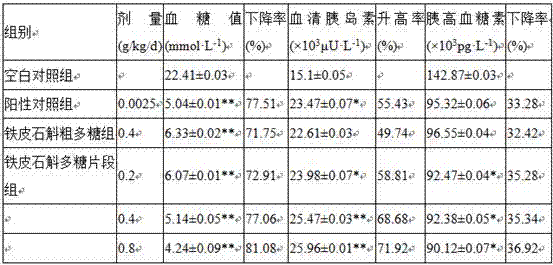

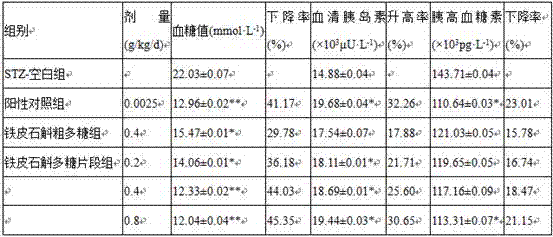

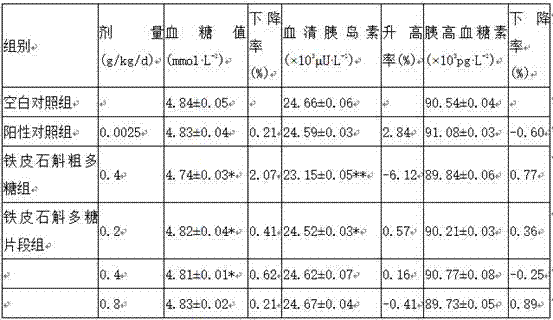

A technology for polysaccharides and extraction methods of Dendrobium officinale, which is applied in the production and fermentation of bulk chemicals, can solve the problems of low polysaccharide extraction rate, poor polysaccharide quality, and unclear polysaccharide components, and achieve high extraction rate and impurity removal rate. High blood sugar reduction rate is good, and the effect of hypoglycemic effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment extracts the described Dendrobium officinale polysaccharide fragments through the following steps:

[0051] (1) Water extraction: pulverize Dendrobium officinale to more than 60 meshes, extract by ultrasonic water leaching 3 times, the water used for each extraction is 25 times by weight of Dendrobium officinale, then get the filtrate and carry out decompression concentration to obtain the described Dendrobium officinale. Water extraction solution; the frequency of ultrasonic is 40kHz, and the time of each water extraction is 20min.

[0052] (2) Deproteinization: add 95% ethanol to the water extract of Dendrobium officinale so that the volume fraction of ethanol in the water extract of Dendrobium officinale is 90%, collect the precipitate, dissolve the precipitate in water, add Sevage reagent , shake the solution for 0.5h, then centrifuge at a speed of 1000r / min, and finally take the supernatant to obtain the crude extract, wherein the Sevage reag...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is:

[0058] In the water extraction of the step (1), the number of times of ultrasonic water immersion extraction is 1 time, and the water used for extraction is 20 times by weight of Dendrobium officinale; the frequency of ultrasonic is 30kHz, and the time of each water immersion extraction is 30min.

[0059] In the deproteinization of the step (2), the volume concentration of ethanol added to the water extract of Dendrobium officinale is 90%, so that the volume fraction of ethanol in the water extract of Dendrobium officinale is 80%, and the solution is shaken 0.3% after adding Sevage reagent. h, and then centrifuge at a speed of 900 r / min, and finally take the supernatant;

[0060] In the step (3) enzymatic hydrolysis modification, the enzymatic hydrolysis modification controls the enzymatic hydrolysis temperature to be 48°C, the enzymatic hydrolysis pH value is 4.5, and the enzymatic hydrolysis reaction time i...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is:

[0064] In the water extraction in the step (1), the number of times of ultrasonic water immersion extraction is 2 times, and the water used for extraction is 20 times by weight of Dendrobium officinale; the frequency of ultrasonic is 50kHz, and the time of each water immersion extraction is 10min.

[0065] In the deproteinization of the step (2), the volume concentration of ethanol added to the water extract of Dendrobium officinale is 92%, so that the volume fraction of ethanol in the water extract of Dendrobium officinale is 82%, and the solution is shaken 0.7% after adding Sevage reagent. h, then centrifuge at 1100r / min, and finally take the supernatant;

[0066] In the step (3) enzymatic hydrolysis modification, the enzymatic hydrolysis modification controls the enzymatic hydrolysis temperature to be 50°C, the enzymatic hydrolysis pH value is 5.2, the enzymatic hydrolysis reaction time is 110 min, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com