Method for treating landfill leachate until it meets the standard and is directly discharged

A landfill leachate and direct discharge technology, which is applied in the direction of contaminated groundwater/leachate treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high concentration of refractory organic matter and paralysis of the treatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

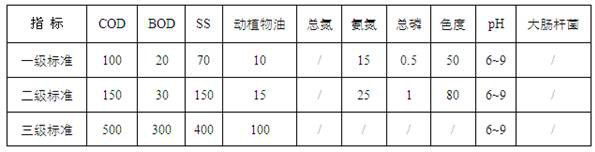

[0095] The leachate produced during the waste stacking process of a waste incineration plant: After testing, the COD in the leachate is 13600mg / L, the ammonia nitrogen is 1800mg / L, the nitrate is 210mg / L, and the total nitrogen is 2500mg / L.

[0096] Adopt processing method provided by the invention to process:

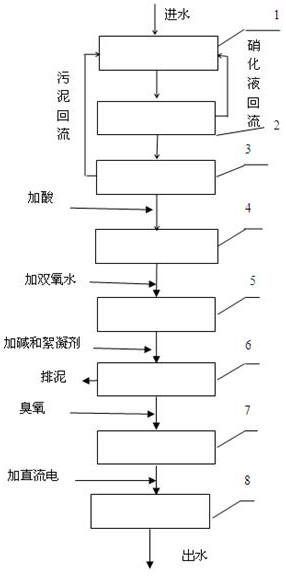

[0097]The leachate to be treated first enters the anoxic biological pool 1, and the sludge concentration in the anoxic biological pool 1 is kept at 9000mg / L, the dissolved oxygen is at 0.2mg / L, and the pH value is 6. The residence time is 50 hours, and the effluent from the anoxic biological pool 1 enters the aerobic biological filter 2;

[0098] In the aerobic biofilter 2, a semi-soft biological filler is suspended, and the filling volume ratio of the biological filler is 40%; the suspended sludge concentration in the aerobic biological filter 2 is kept at 5000 mg / L, and the dissolved oxygen is at 6.0 mg / L. The pH value is 9, and the hydraulic retention time is 50 ho...

Embodiment 2

[0107] The leachate produced by a garbage treatment plant: COD is 4500mg / L, ammonia nitrogen is 1200mg / L, nitrate is 110mg / L, and total nitrogen is 1500mg / L.

[0108] Adopt the processing method provided by the present invention to process: the leachate to be treated first enters the anoxic biological pool 1, and maintains that the sludge concentration in the anoxic biological pool 1 is 5000 mg / L, dissolved oxygen is 0.3 mg / L, and the pH value is 7. The mud-water mixing method adopts submerged mechanical stirring, and the hydraulic retention time is 25 hours. The effluent from the anoxic biological pool 1 enters the aerobic biological filter 2;

[0109] Keep the suspended sludge concentration in the aerobic biofilter 2 at 3000mg / L, the dissolved oxygen at 4.0mg / L, the pH value at 8, and the hydraulic retention time at 25 hours. Part of the organic matter and ammonia nitrogen in the water are produced by the aerobic microorganisms attached to the carrier decomposed into CO 2 、...

Embodiment 3

[0118] The leachate produced by a landfill: COD is 3000mg / L, ammonia nitrogen is 630mg / L, nitrate is 58mg / L, and total nitrogen is 740mg / L.

[0119] Adopt the treatment method provided by the present invention to process: the leachate to be treated first enters the anoxic biological pool 1, maintains that the sludge concentration in the anoxic biological pool is 3000mg / L, dissolved oxygen is at 0.4mg / L, and the pH value is 9, muddy water The mixing method adopts submerged mechanical stirring, the hydraulic retention time is 10 hours, and the effluent from the anoxic biological pool 1 enters the aerobic filter tank 2;

[0120] Keep the suspended sludge concentration in the aerobic filter 2 at 1000mg / L, the dissolved oxygen at 2.0mg / L, the pH value at 8, and the hydraulic retention time at 10 hours. Part of the organic matter and ammonia nitrogen in the water are decomposed by the aerobic microorganisms attached to the carrier for CO 2 、H 2 O, NO 3 2- , the effluent part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com