A method for advanced treatment of oil refining alkali slag

A technology for refining alkali residue and advanced treatment, which is applied in the fields of natural water treatment, chemical instruments and methods, and multi-stage water/sewage treatment. The effect of easy equipment manufacturing industrialization and easy stereotyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

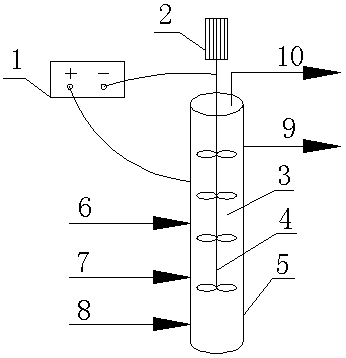

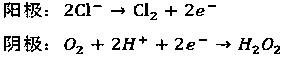

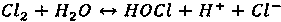

Embodiment 1

[0037] Catalytic gasoline alkali slag in a refinery, where COD is 3.21×10 5 mg / L, sulfide is 1.76×10 4 mg / L, volatile phenol 1.07×10 5 mg / L. The method of the present invention is used for treatment. Firstly, hydrochloric acid is introduced for acidification, and a certain amount of air is introduced for blowing off. At the same time, the stirrer is turned on. When the pH value of the alkali residue in the reactor drops to 7, the addition of hydrochloric acid is stopped. When the acidification process is completed, the motor and the blowing of inert gas are turned off, the acidified alkali residue is allowed to stand, and the oil phase on the liquid surface is cut out to the outside of the reactor. The negative pole of the DC power supply is connected to the stirrer, and the positive pole of the power supply is connected to the Ti-PbO of the reactor 2 The electrodes are connected. Of which Ti-PbO 2 The electrode adopts the method of electrodeposition, and a layer of PbO is depo...

Embodiment 2

[0040] Liquid hydrocarbon alkali residue of a refinery, in which COD is 7.97×10 4 mg / L, sulfide is 4×10 3 mg / L, volatile phenol 1.4×10 4 mg / L. The method of the present invention is used for treatment. Firstly, hydrochloric acid is introduced for acidification, and a certain amount of air is introduced for blowing off. At the same time, the stirrer is turned on. When the pH value of the alkali residue in the reactor drops to 7, the addition of hydrochloric acid is stopped. When the acidification process is completed, the motor and the blowing of inert gas are turned off, the acidified alkali residue is allowed to stand, and the oil phase on the liquid surface is cut out to the outside of the reactor. The negative pole of the DC power supply is connected to the stirrer, and the positive pole of the power supply is connected to the Ti-PbO of the reactor 2 The electrodes are connected. Of which Ti-PbO 2 The electrode adopts the method of electrodeposition, and a layer of PbO is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com