Treatment method of high-alcohol wastewater

A treatment method and technology for waste water, applied in water/sewage treatment, heating water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of difficult to achieve effluent, strict discharge index requirements, high treatment costs, and reduce treatment costs. The effect of high cost and operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

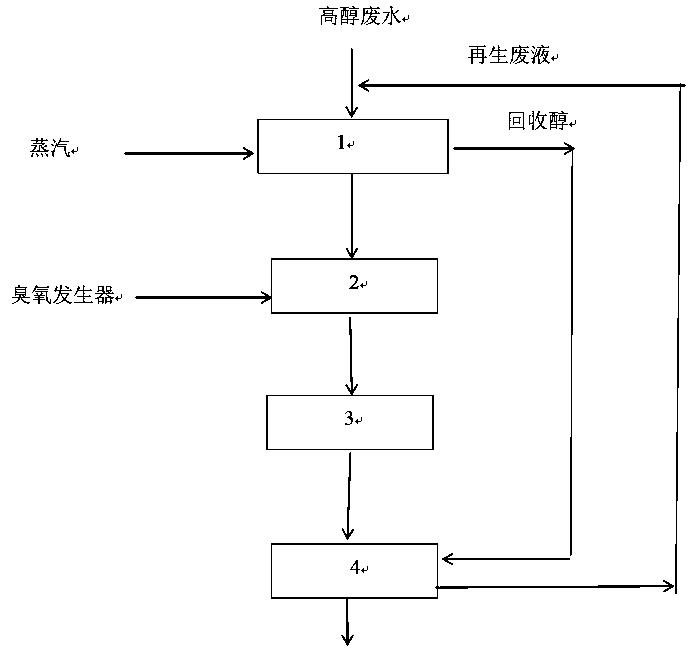

Image

Examples

Embodiment 1

[0044] A certain pigment production wastewater contains methanol and other organic substances: COD is 26000mg / L, ammonia nitrogen is 110mg / L, and methanol content is 5000mg / L.

[0045] The treatment method provided by the invention is used for treatment: the wastewater to be treated first passes through the rectification system 1, and at the same time, the temperature of the wastewater is raised to 75° C. by introducing steam, and most of the alcohols in the wastewater are removed by utilizing the low boiling point of alcohols. Enter the ozone catalytic oxidation system 2 to oxidize the alcohols, the ozone dosage is 500mg / L, the oxidation time is 120 minutes, the ozone catalytic effluent enters the biochemical system 3, the anoxic tank sludge concentration is 6000mg / L, the aerobic tank The sludge concentration is 5000mg / L; the dissolved oxygen in the anoxic tank is 0.2mg / L, and the dissolved oxygen in the aerobic tank is 6.0mg / L; the hydraulic retention time in the anoxic tank ...

Embodiment 2

[0048] An alcoholic fermentation wastewater contains ethanol and other organic substances: COD is 11000mg / L, ammonia nitrogen is 50mg / L, and ethanol content is 2100mg / L.

[0049] The treatment method provided by the invention is used for treatment: the wastewater to be treated first passes through the rectification system 1, and at the same time, the temperature of the wastewater is raised to 65° C. by introducing steam, and most of the alcohols in the wastewater are removed by utilizing the low boiling point of alcohols. Enter the ozone catalytic oxidation system 2 to oxidize the alcohols, the ozone dosage is 200mg / L, the oxidation time is 30 minutes, the ozone catalytic effluent enters the biochemical system 3, the anoxic tank sludge concentration is 4000mg / L, the aerobic tank The sludge concentration is 3000mg / L; the dissolved oxygen in the anoxic tank is 0.5mg / L, and the dissolved oxygen in the aerobic tank is 2.0mg / L; the hydraulic retention time of the anoxic tank is 20 h...

Embodiment 3

[0052] A pharmaceutical wastewater contains methanol and other organics: COD is 16500mg / L, ammonia nitrogen is 880mg / L, and methanol content is 3200mg / L.

[0053] The treatment method provided by the invention is used for treatment: the wastewater to be treated first passes through the rectification system 1, and at the same time, the temperature of the wastewater is raised to 70° C. by introducing steam, and most of the alcohols in the wastewater are removed by utilizing the low boiling point of alcohols. Enter the ozone catalytic oxidation system 2 to oxidize the alcohols, the ozone dosage is 280mg / L, the oxidation time is 600 minutes, the ozone catalytic effluent enters the biochemical system 3, the anoxic tank sludge concentration is 5000mg / L, the aerobic tank The sludge concentration is 5000mg / L; the dissolved oxygen in the anoxic tank is 0.3mg / L, and the dissolved oxygen in the aerobic tank is 4.0mg / L; the hydraulic retention time of the anoxic tank is 30 hours, and the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com