Mechanism capable of controlling machining depth, radial drilling machine and machining method

A technology of processing depth and radial drilling machine, applied in the field of thread processing, can solve the problems that tile processing cannot meet the requirements of engineering applications, the qualified rate of finished parts of floating tiles is low, and the qualified rate of thread processing is low, etc., so as to achieve the realization of thread processing. Integrity, high-precision control, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

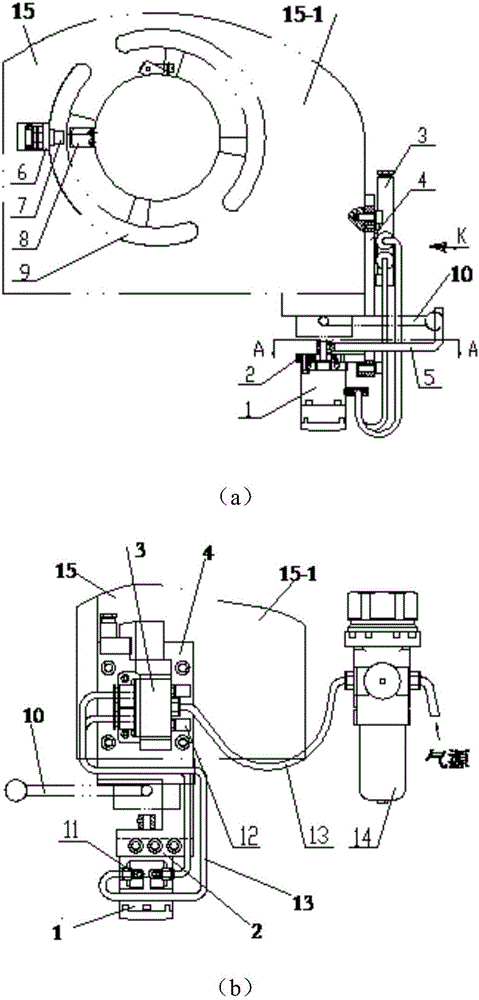

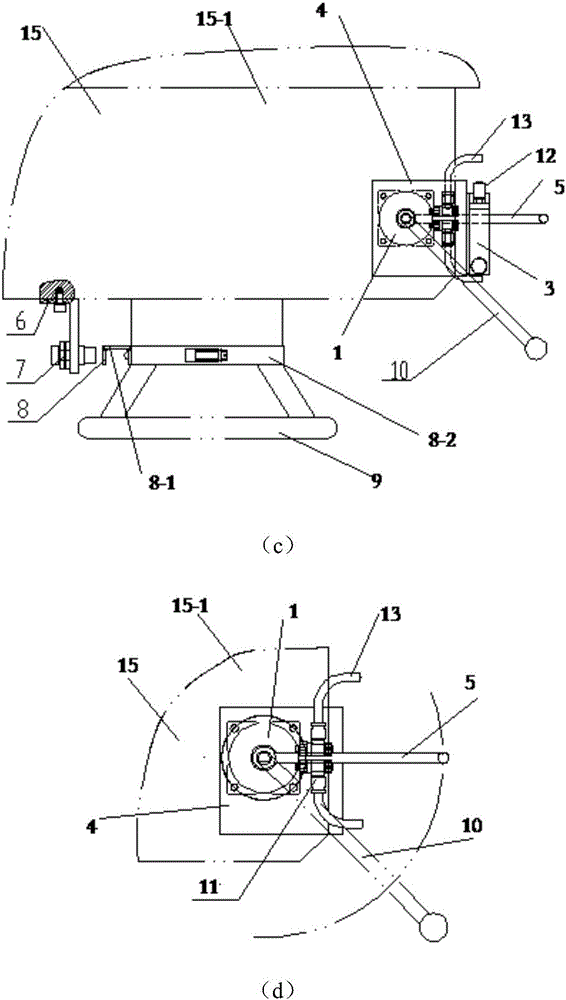

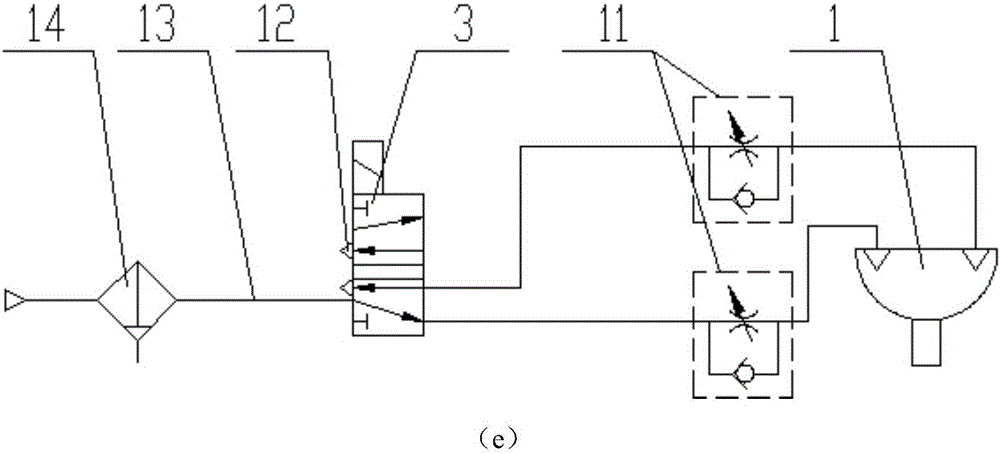

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] Such as Figure 1 to Figure 10 As shown, the mechanism of the controllable processing depth of the present invention includes a swing cylinder 1, the output shaft of the swing cylinder 1 is connected with a driving rod 5, and the driving rod 5 swings under the drive of the swing cylinder 1, and the gas circuit of the swing cylinder 1 is connected There is a solenoid valve 3, and the solenoid valve 3 is used to switch the air path of the swing cylinder 1 to change the rotation direction of the output shaft of the swing cylinder. The solenoid valve 3 is connected to a controller, and the controller is connected to a position detection device. The swing cylinder 1 A speed regulating valve 11 is respectively arranged on the gas path between the solenoid valve 3, a muffler 12 is installed on the solenoid valve 3, and a filter pressure reducing valve 14 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com