High-sulfate wastewater treatment method

A treatment method, high sulfate technology, applied in the field of wastewater treatment and purification, can solve the problems of high treatment cost, high cost, high cost, etc., and achieve the effect of reducing treatment cost and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

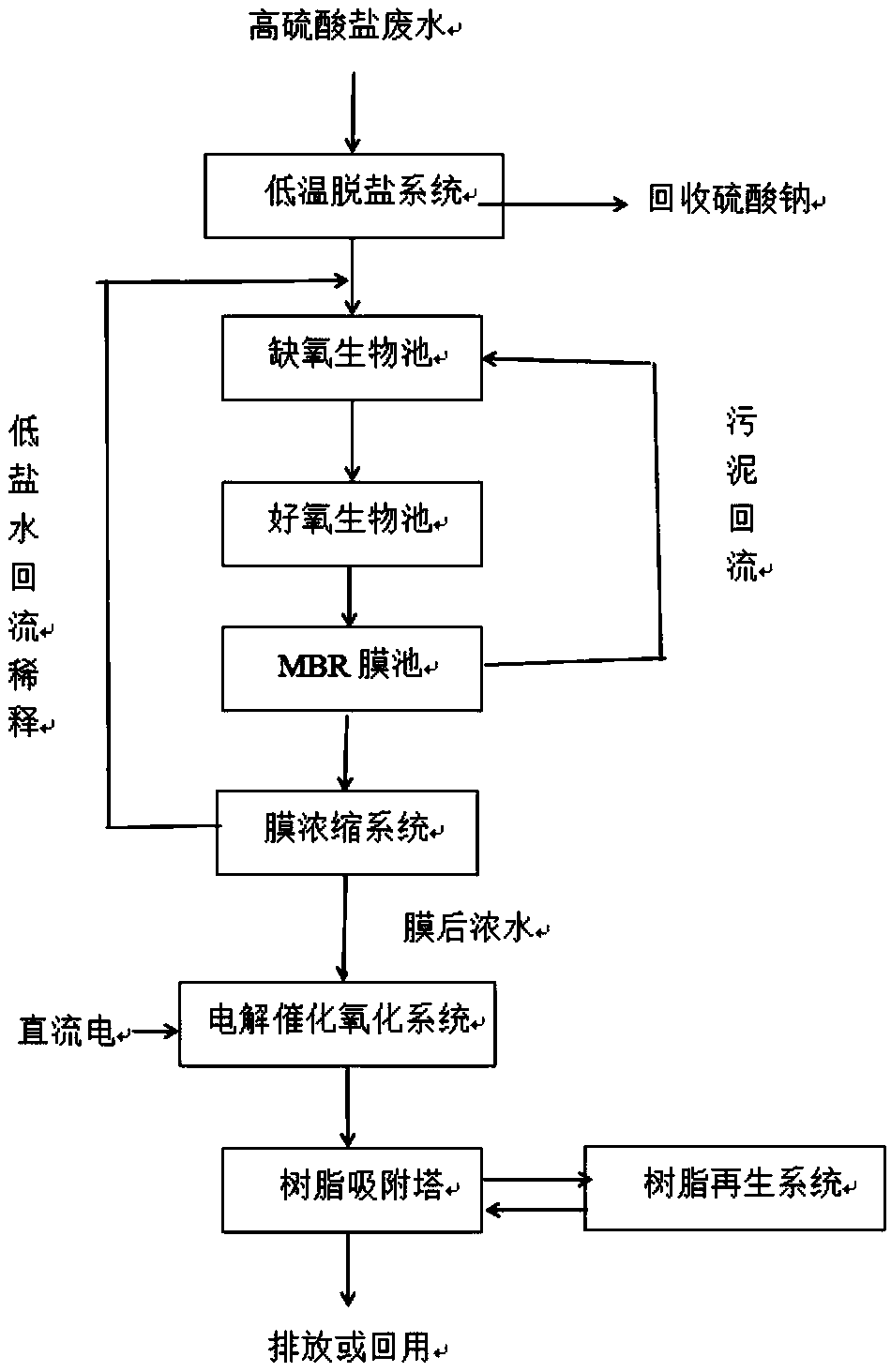

Image

Examples

Embodiment 1

[0023] A certain pigment production wastewater: COD is 26000mg / L, ammonia nitrogen is 1100mg / L, sodium sulfate content is 150g / L.

[0024] Adopt the processing method provided by the present invention to process: the waste water to be treated first passes through the low-temperature desalination system, utilizes the characteristic that the solubility of sulfate reduces at low temperature to separate out part of the sulfate, and the sodium sulfate content in the effluent is 28g / L, and then enters the anoxic biological pool, Therefore, when the system is started, fresh industrial water twice the amount of water is added for dilution to ensure that the salt content of the biochemical system is 9.5g / L. System sludge concentration, the sludge in the MBR pool returns to the front end of the anoxic biological pool, and the reflux ratio is 200%; the COD of the effluent from the MBR membrane pool is 120mg / L, enters the membrane concentration system, and the sulphate content of the efflu...

Embodiment 2

[0027] A flue gas desulfurization wastewater: COD is 8000mg / L, sodium sulfate content is 110g / L.

[0028] Adopt the processing method provided by the present invention to process: the waste water to be treated first passes through the low-temperature desalination system, utilizes the characteristic that the solubility of sulfate reduces at low temperature to separate out part of the sulfate, and the sodium sulfate content in the effluent is 30g / L, and then enters the anoxic biological pool, Therefore, when the system is started, fresh industrial water twice the amount of water is added for dilution to ensure that the salt content of the biochemical system is 10g / L. Sludge concentration, the sludge in the MBR pool returns to the front of the anoxic biological pool, and the reflux ratio is 200%; the COD of the effluent from the MBR membrane pool is 90mg / L, enters the membrane concentration system, and the sulfate content of the effluent is 0.5% after being concentrated for 3 time...

Embodiment 3

[0031] A pesticide production wastewater: COD is 11200mg / L, sodium sulfate content is 90g / L.

[0032] Adopt the processing method provided by the present invention to process: the waste water to be treated first passes through the low-temperature desalination system, utilizes the characteristic that the solubility of sulfate reduces at low temperature to separate out part of the sulfate, and the sodium sulfate content in the effluent is 29g / L, and then enters the anoxic biological pool, Therefore, when the system is started, fresh industrial water twice the amount of water is added for dilution to ensure that the salt content of the biochemical system is 10g / L. Sludge concentration: the sludge in the MBR pool flows back to the front of the anoxic biological pool, and the reflux ratio is 200%; the COD of the effluent from the MBR membrane pool is 180mg / L, and it enters the membrane concentration system. The COD is 4mg / L, and it is returned to the front of the anaerobic biologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com