Machine for grinding or cutting plane curve groove

A plane curve and curve technology, applied in the field of plane curve groove grinding machine tools, can solve the problems of low production efficiency, high manufacturing cost, and inability to process, and achieve the effect of realizing automatic production, reducing production cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

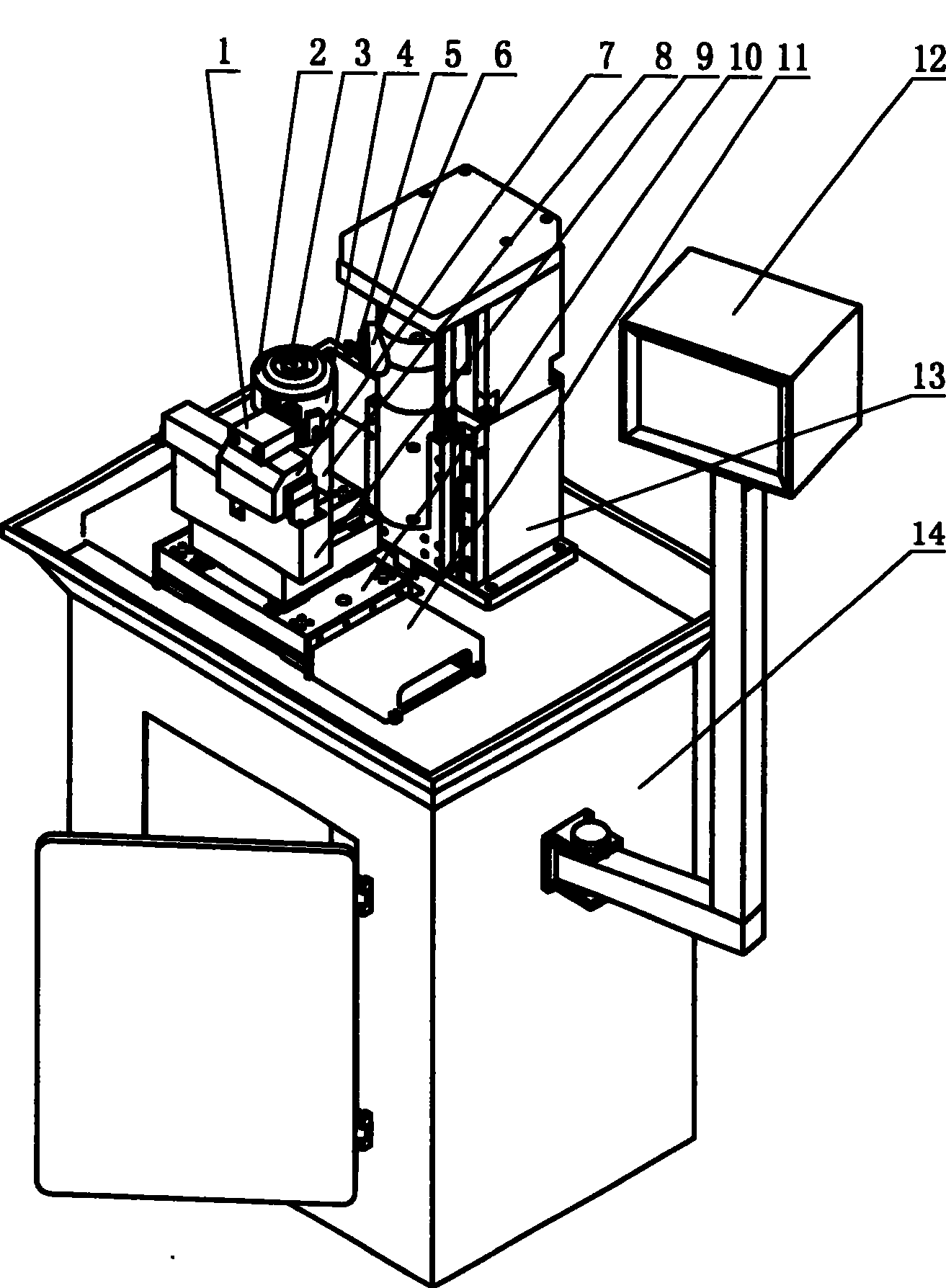

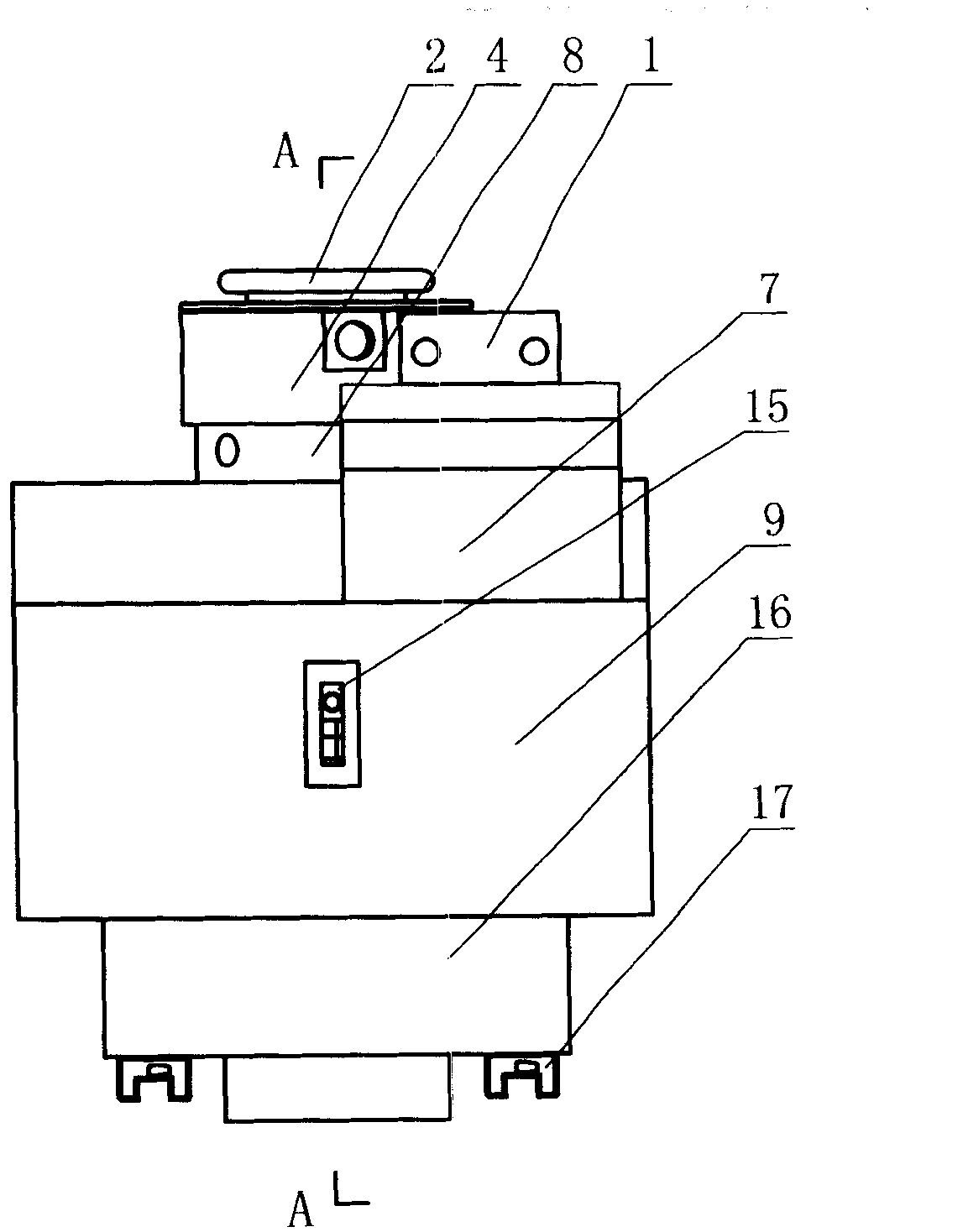

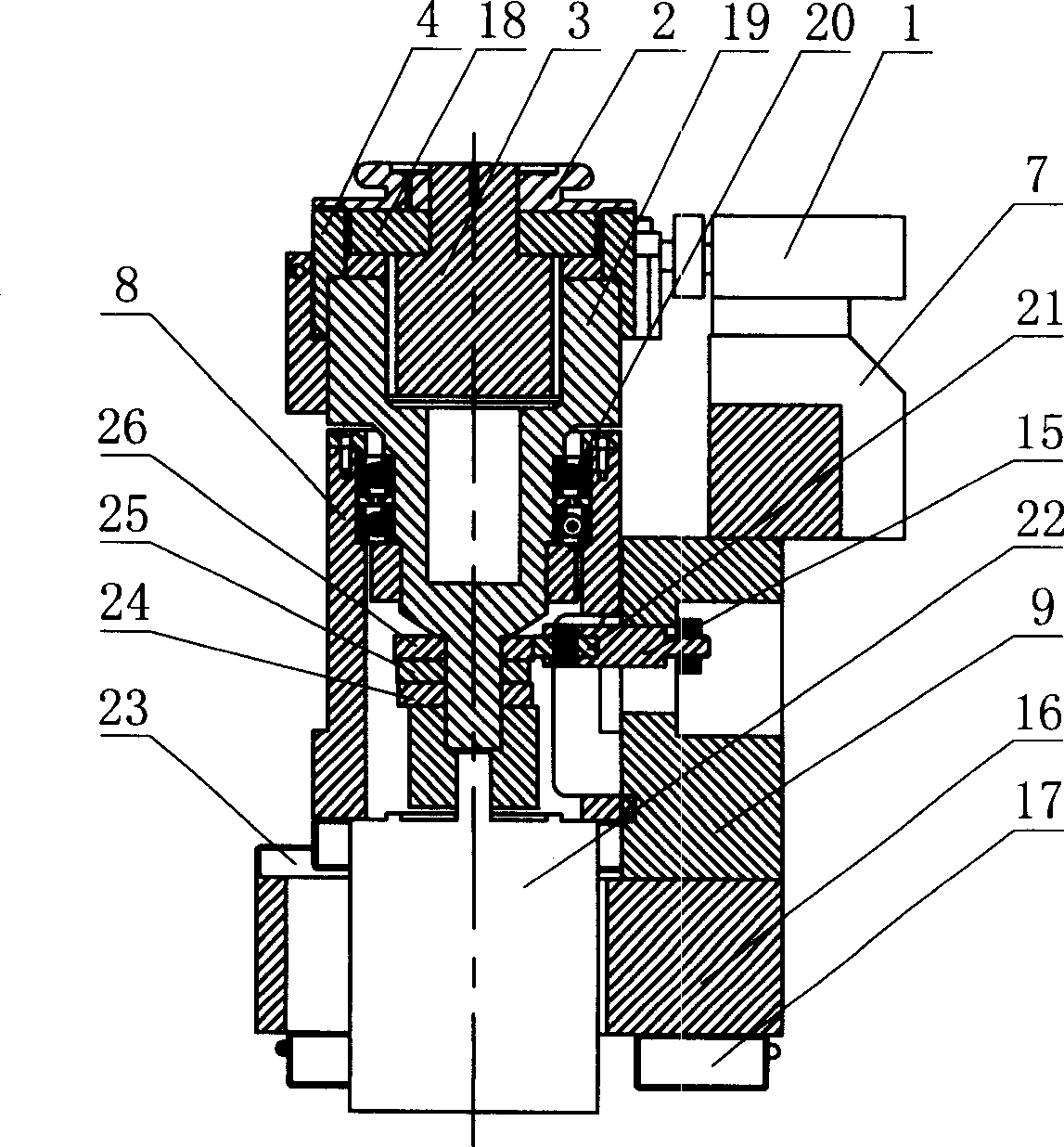

[0027] The plane curve groove grinding machine tool is composed of a base 14, a position adjustment mechanism, a curve synthesis mechanism, an indexing mechanism, a grinding wheel running and feeding device, and an electric control device 12. The position adjustment mechanism is installed on the base, and the curve synthesis mechanism is installed on the base. On the position adjustment mechanism, the indexing mechanism is installed on the curve synthesis mechanism, and the grinding wheel running and feeding device is fixed on the base at the side of the position adjustment mechanism.

[0028] In order to clearly describe the technical structure of the present invention, it is described in four parts below:

[0029] 1. Position adjustment me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com