Underwater high-precision hole forming method based on electrical discharge machining

An electric spark and hole forming technology, applied in the field of EDM, to reduce the risk of tap breakage, reduce taper, and improve the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described below in conjunction with the drawings and specific embodiments:

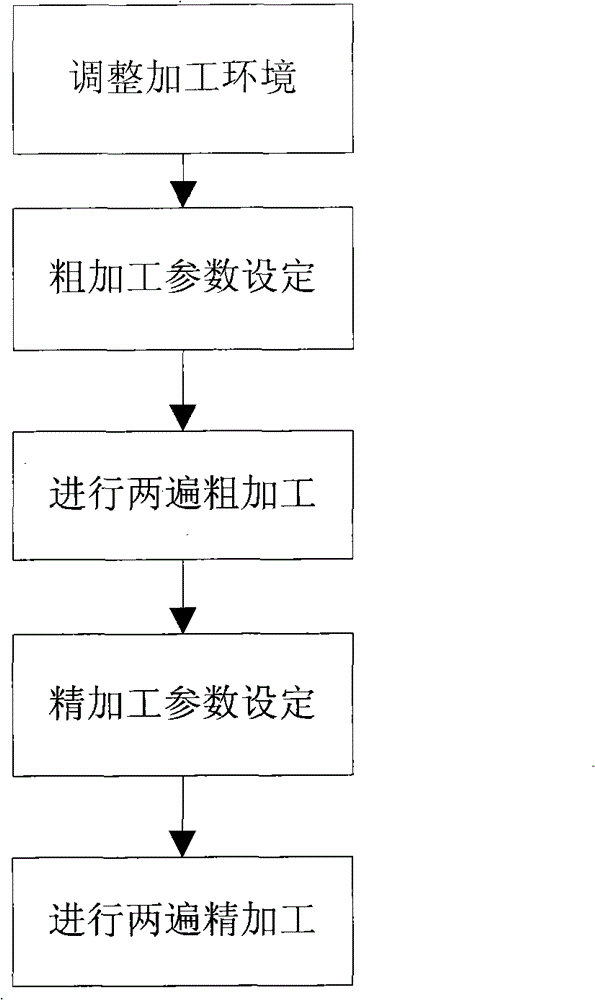

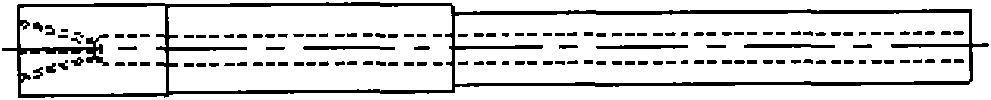

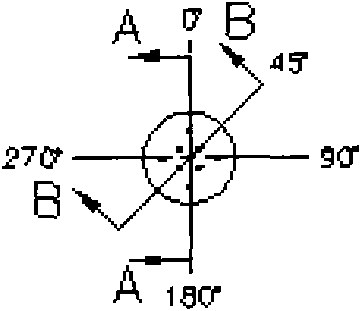

[0074] Take the underwater EDM forming of the M20 threaded bottom hole on the outer wall of the underwater nuclear reactor basket as an example, the M20 threaded bottom hole needs to be machined on the outer wall of the basket, such as figure 1 As shown, two-pass roughing and two-pass finishing are used for forming, and the specific implementation process is as follows:

[0075] Step 1. Since the processing is carried out in boron-containing water, first turn on the underwater vacuum cleaner, if necessary, start the water circulation system of the power plant to absorb impurities that may affect the processing, and make the water clear enough for EDM; at the same time, it is necessary to monitor the conductivity of the boron-containing water The conductivity is maintained at 4~7μS / cm(25℃);

[0076] Step 2. Install the rough-machined electrode; the electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com