A kind of ferric trifluoride/lithium hexafluoroferrite composite cathode material, its preparation and application

A composite positive electrode material, lithium hexafluoroferrate technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of long synthesis process, expensive raw materials, and decreased energy density of batteries, and achieve low cost and preparation The process is simple and the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

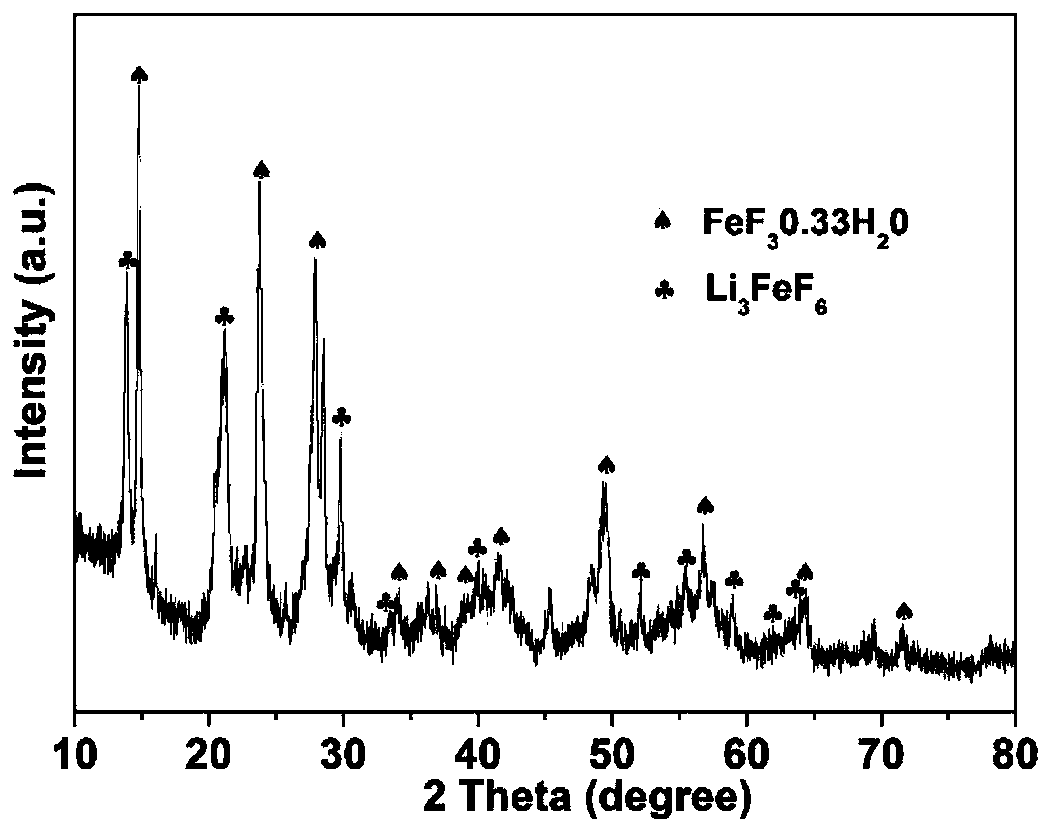

[0077] Take 1.5g of FeF with a particle size of 200nm 3 ·3H 2 O was added to 40mL of ethanol, and the mixed solution was ultrasonicated for 30 minutes. Another 30mL of ethanol was taken, and 0.025g of lithium chloride was added, and stirred to dissolve all the lithium chloride in the ethanol solution. The ethanol was added dropwise at a rate of 1mL / min to the FeF 3 ·3H 2 In the ethanol solution of O, the reaction temperature is 25°C. After continuous stirring and reaction for 12 hours, centrifuge and dry in an oven at 60°C for 24 hours. The heating rate is heated to 225°C, and the heating is continued for 10 hours, and the whole process is protected by argon to obtain FeF with a particle size of 200nm. 3 0.33H 2 O / Li 3 FeF 6 Composite material, Li 3 FeF 6 The thickness of the protective layer was 0.5 nm. After charge and discharge tests, the first discharge specific capacity of this composite material is 480mAh / g, and the capacity is still 150mAh / g after 100 cycles. ...

Embodiment 2

[0079] Take 1.5g of FeF with a particle size of 200nm 3 ·3H 2 O was added to 40mL of ethanol, and the mixed solution was ultrasonicated for 30 minutes, and another 30mL of ethanol was taken, and 0.05g of lithium chloride was added, and stirred to dissolve all the lithium chloride in the ethanol solution. The ethanol was added dropwise at a rate of 1mL / min to the FeF 3 ·3H 2 In the ethanol solution of O, the reaction temperature is 25°C. After continuous stirring and reaction for 12 hours, centrifuge and dry in an oven at 60°C for 24 hours. The heating rate is heated to 225°C, and the heating is continued for 10 hours, and the whole process is protected by argon to obtain FeF with a particle size of 200nm. 3 0.33H 2 O / Li 3 FeF 6 Composite material, Li 3 FeF 6 The thickness of the protective layer was 1 nm. After charge and discharge tests, the first discharge specific capacity of this composite material is 497mAh / g, and the capacity is still 174mAh / g after 100 cycles. ...

Embodiment 3

[0081] Take 1.5g of FeF with a particle size of 200nm 3 ·3H 2 O was added to 40mL of ethanol, and the mixed solution was ultrasonicated for 30 minutes, and another 30mL of ethanol was taken, and 0.2g of lithium chloride was added, and stirred to dissolve all the lithium chloride in the ethanol solution. The ethanol was added dropwise at a rate of 1mL / min to the FeF 3 ·3H 2 In the ethanol solution of O, the reaction temperature is 25°C. After continuous stirring and reaction for 12 hours, centrifuge and dry in an oven at 60°C for 24 hours. The heating rate is heated to 225°C, and the heating is continued for 10 hours, and the whole process is protected by argon to obtain FeF with a particle size of 200nm. 3 0.33H 2 O / Li 3 FeF 6 Composite material, Li 3 FeF 6 The thickness of the protective layer was 20 nm. After charge and discharge tests, the first discharge specific capacity of this composite material is 380mAh / g, and the capacity is still 80mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com