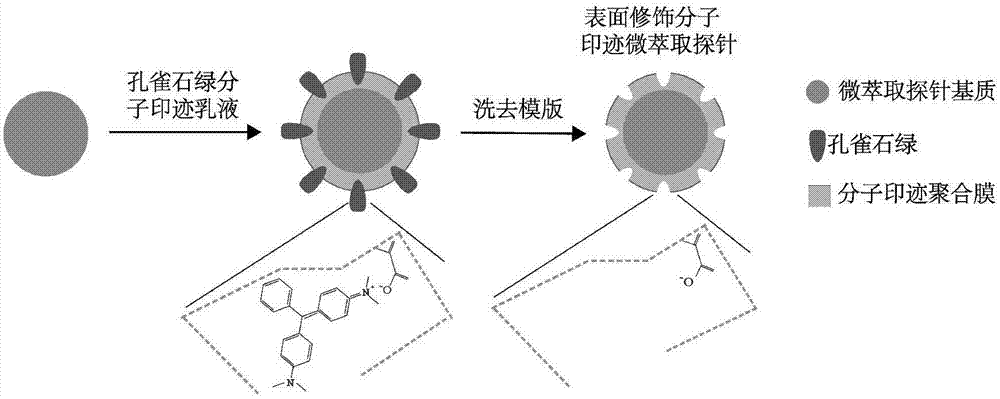

Surface-modified molecular-imprinted solid-phase microextraction probe and preparation and application thereof

A molecular imprinting and surface modification technology, applied in the field of extraction probes, can solve the problems of difficult separation, tedious and time-consuming, etc., and achieve the effects of rapid analysis, good adsorption performance, strong selectivity and enrichment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 solid-phase microextraction probe

[0044] 1. Take 24mL deionized water, add 0.1g methacrylic acid, 0.05g acrylic acid, 0.2g styrene, 0.2g hydroxypropyl acrylate, 1.5g butyl acrylate, 1.5g 2-ethylhexyl acrylate functional monomer And 0.05g octylphenol polyoxyethylene ether, 0.05g sodium lauryl sulfate emulsifier, stir 15min in emulsifier (20000rpm / min) and prepare pre-emulsion for subsequent use.

[0045] 2. Add 13mL of deionized water, 0.1g of sodium bicarbonate, and about 7.5g of pre-emulsion into a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 80°C under stirring at 250rpm / min, and then add half 5mL 0.11mol / L potassium persulfate initiator, after reacting for 1h, a bluish seed emulsion was obtained.

[0046] 3. Reduce the stirring speed, drop the remaining pre-emulsion and potassium persulfate solvent into the seed emulsion within 4 hours to obtain an acrylate emulsion, and continue to drop vin...

Embodiment 2

[0051] 1. Take 24mL deionized water, add 0.3g methacrylic acid, 0.15g acrylic acid, 0.6g styrene, 0.6g hydroxypropyl acrylate, 4.5g butyl acrylate, 4.5g 2-ethylhexyl acrylate functional monomer With 0.15g sodium lauryl sulfate and secondary octylphenol polyoxyethylene ether emulsifier, stir 15min in emulsifying machine (10000rpm / min) and prepare pre-emulsion for subsequent use.

[0052] 2. Add 13mL of deionized water, 0.1g of sodium bicarbonate, and about 7.5g of pre-emulsion into a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, raise the temperature to 110°C under stirring at 250rpm / min, and then add half 5mL of 0.11mol / L azobisisobutyronitrile initiator, after reacting for 3h, a bluish seed emulsion was obtained.

[0053] 3. Reduce the stirring speed, drop the remaining pre-emulsion and potassium persulfate solvent into the seed emulsion within 4 hours to obtain an acrylate emulsion, and continue to drop vinyl tris (β-methoxyethoxy) silane, Afte...

Embodiment 3

[0058] 1. Take 24mL deionized water, add 0.51g methacrylic acid, 0.26g acrylic acid, 1g styrene, 1g hydroxypropyl acrylate, 7.7g butyl acrylate, 7.7g 2-ethylhexyl acrylate functional monomer and 0.26 g octylphenol polyoxyethylene ether, 0.26g sodium lauryl sulfate emulsifier, stirred in an emulsifier (30000rpm / min) for 15min to prepare a pre-emulsion for subsequent use.

[0059] 2. Add 13mL of deionized water, 0.1g of sodium bicarbonate, and about 7.5g of pre-emulsion into a four-necked flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 70°C under stirring at 250rpm / min, and then add half 5mL of 0.11mol / L benzoyl peroxide initiator, after reacting for 5h, the seed emulsion of pan-blue light was obtained.

[0060] 3. Reduce the stirring speed, drop the remaining pre-emulsion and potassium persulfate solvent into the seed emulsion within 4 hours to obtain an acrylate emulsion, and continue to drop vinyl tris (β-methoxyethoxy) silane, After reacting for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com