Method and apparatus for manufacturing titania

A technology of titanium dioxide and preparation equipment, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology for materials and surface science, etc. It can solve the problems of difficulty in applying common equipment to continuous processes, longer preparation time, and insufficient effects, etc. problems, to achieve the effect of improving process efficiency, ensuring quality uniformity, and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The invention relates to a preparation method and a preparation device for efficiently and environmentally friendly preparation of titanium dioxide through a continuous process.

[0067] The conventional sulfuric acid method, hydrochloric acid method, sol-gel method and other titanium dioxide preparation methods have defects in process efficiency, safety, economy, and productivity, and generate a large amount of waste, so they have a greater impact on the environment .

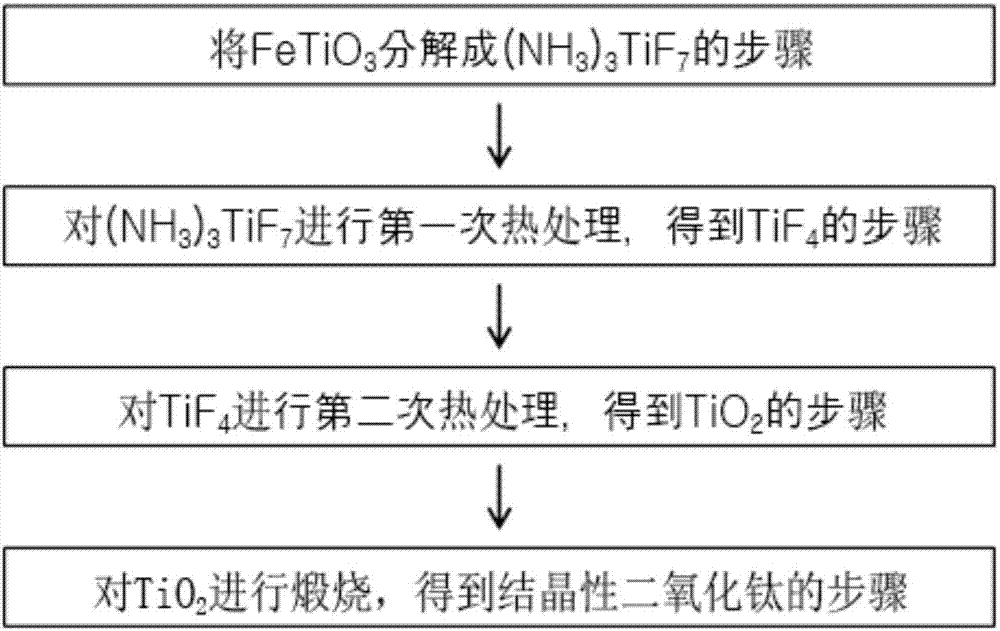

[0068] In view of this, the present invention provides a preparation method and preparation device of titanium dioxide, which do not use sulfuric acid, hydrochloric acid and other dangerous or high raw material cost starting materials, but use gaseous ammonia or hydrogen fluoride to decompose ilmenite, thereby enabling Selectively prepare anatase or rutile titanium dioxide.

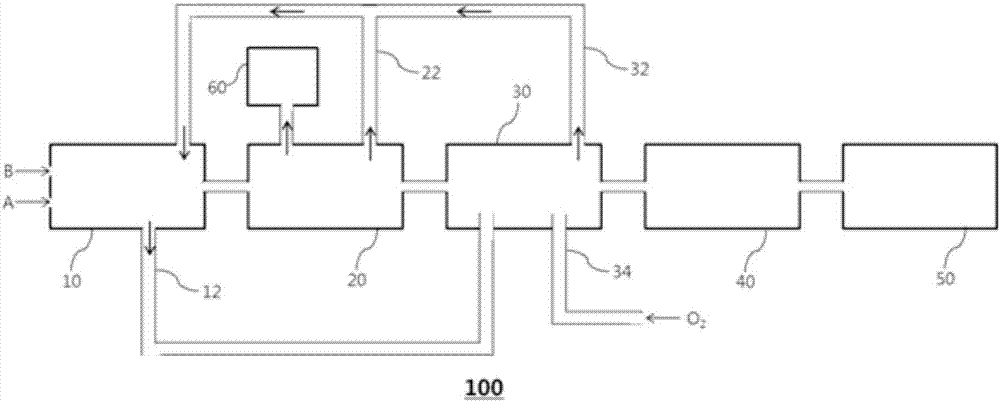

[0069] In addition, the preparation method and preparation device of titanium dioxide involved in the present invention are carried out...

Embodiment 1

[0142] Put a carbonaceous bowl (bowl) into a 30L rotary electric furnace to prevent internal coating, then put in 250g Ilmenite, 1250g H 2 SiF 6 (l), in NH 3 (g) Mixing and heating at 180°C for 5 hours in an atmosphere. The generated titanium compound is automatically moved to the second step section of the 30L rotary electric furnace by rotation, where impurities are removed by the first heat treatment at 350° C. for 1 hour, thereby preparing titanium fluoride.

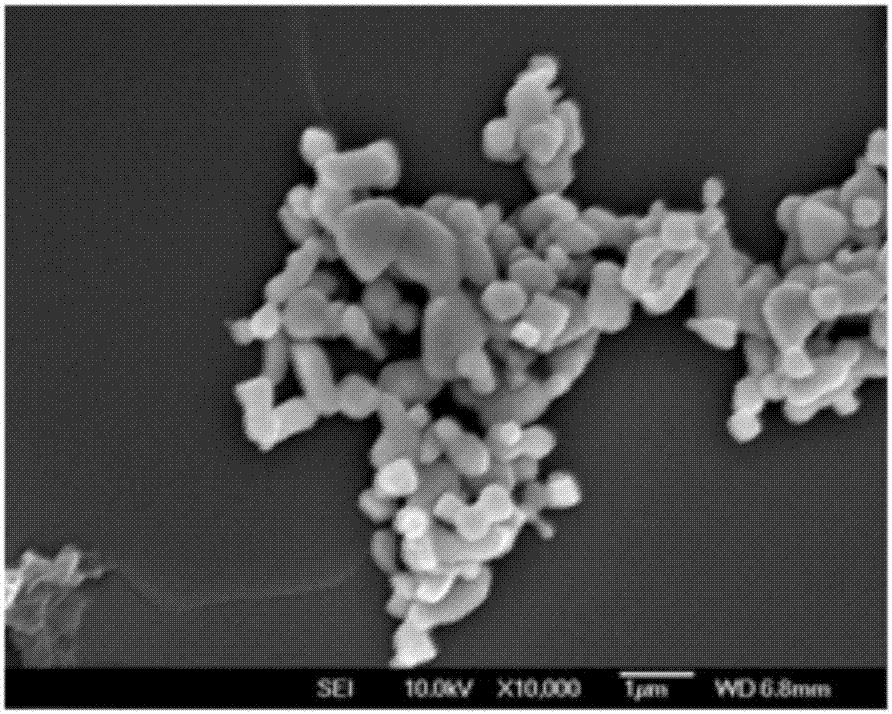

[0143] Next, the titanium fluoride was moved to the upper end of the rotary electric furnace, and the titanium fluoride was subjected to a second heat treatment at 650°C for 4 hours, thereby preparing titanium dioxide. The obtained titanium dioxide was moved to a titanium dioxide production reactor and reacted at 1100° C. for 2 hours, thereby producing crystalline titanium dioxide.

Embodiment 2

[0145] Except that the calcination temperature in the titanium dioxide production reactor was changed to 1000° C., crystalline titanium dioxide was prepared by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com