Continuous dyeing-finishing process for Xinlun T3000/polyester low-elasticity yarn interwoven and tatted cloth

A technology of polyester low elastic yarn and Xinlun, which is applied in dyeing, textile and papermaking, fiber treatment, etc. It can solve the problems of inconsistent quality, large product vat difference, poor gloss of cloth surface, etc., and achieve stable product quality and elasticity , uniform dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

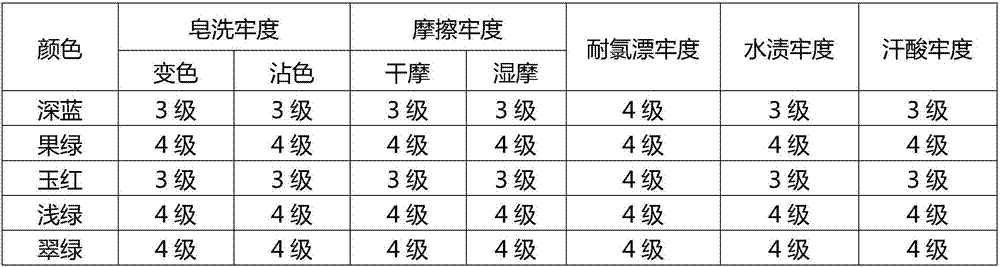

Examples

Embodiment 1

[0024] The continuous dyeing and finishing process of medium-dark Xinlun T3000 / polyester low-stretch yarn interwoven woven fabrics, the process sequence is: fabric turning-seaming-desizing-steaming-setting-dyeing-reduction cleaning-finishing tentering

[0025] Desizing plan: caustic soda 15g / L, scouring agent 6g / L, penetrant 5g / L; solution temperature 90°C, roll up and stack for 4 hours, wash with hot water at 90°C.

[0026] Steaming scheme: caustic soda 10g / L, scouring agent 2g / L, penetrant 2g / L; solution temperature 90°C, steaming temperature 102°C, steaming time 90 seconds, 90°C hot water washing.

[0027] Shaping scheme: temperature 150°C, time 30 seconds.

[0028] Staining scheme: the staining solution contains anti-swimming agent SL10g / L, acetic acid 1g / L. The temperature of the three-section pre-oven is 60°C, 80°C, and 90°C, the baking temperature is 180°C, and the baking time is 90 seconds. The temperature of the three-section pre-oven is gradually raised to prevent ...

Embodiment 2

[0032] Continuous dyeing and finishing process of light-colored Xinlun T3000 / polyester low elastic yarn interwoven woven fabric, the process sequence is: fabric turning-seaming-desizing-steaming-setting-dyeing-reduction cleaning-finishing tentering.

[0033] Desizing scheme: caustic soda 20g / L, hydrogen peroxide 12g / L, scouring agent 8g / L, penetrant 5g / L, stabilizer 8g / L, degreaser 5g / L, chelating dispersant 4g / L. The solution is at room temperature, rolled up and stacked for 20 hours, and washed with hot water at 90°C.

[0034] Steaming scheme: caustic soda 10.5g / L, scouring agent 2.5g / L, penetrant 2.5g / L; solution temperature 91°C, steaming temperature 100°C, steaming time 100 seconds, 90°C hot water washing.

[0035] Shaping program: temperature 150°C, time 33 seconds.

[0036] Staining scheme: the staining solution contains anti-swimming agent SL10.5g / L, acetic acid 1g / L. The temperature of the three pre-baking ovens is 61°C, 81°C, and 91°C, the baking temperature is 180°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com