Method for improving electrical conductivity of graphene thin films prepared by normal-pressure chemical gas-phase sedimentation method

A technology of atmospheric pressure chemical vapor phase and graphene film, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of poor electrical conductivity of graphene film, and achieve the suppression of non-uniform nucleation process , Improve electrical conductivity, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

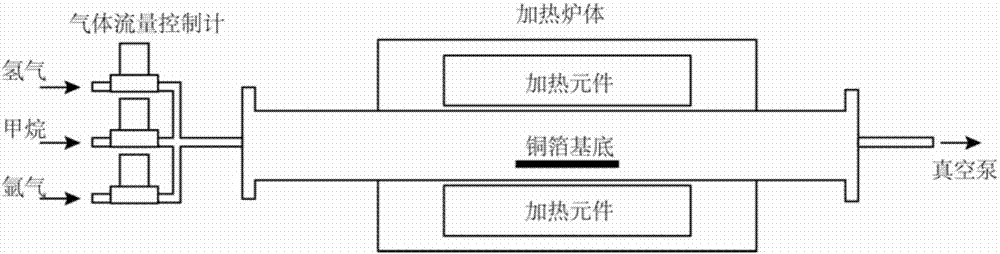

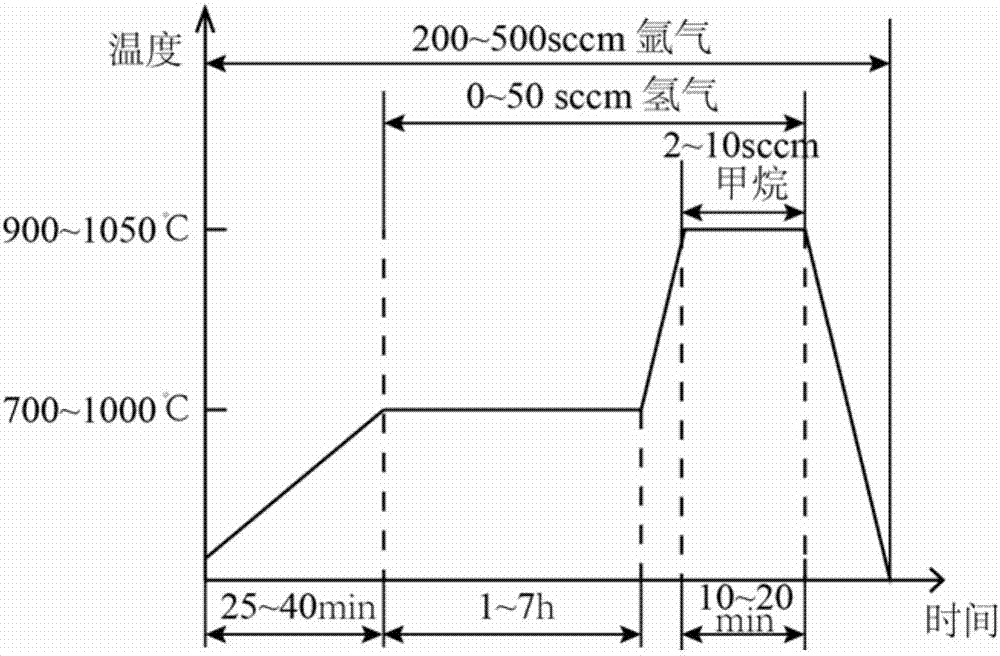

[0031] (1) Put 2×2cm copper foil into acetone, ethanol, and deionized water for 10 minutes for ultrasonic cleaning respectively to remove oil and other organic impurities on the surface of the copper foil, then dry it with high-pressure gas and place it in a quartz crucible;

[0032] (2) Put the quartz crucible with copper foil into the constant temperature zone of the tube furnace, then evacuate the quartz tube, feed Ar gas to maintain the normal pressure in the tube; feed 300 sccm argon, 40 sccm hydrogen, and heat from room temperature for 30 minutes to 700°C, and then heat-treat the copper foil substrate at this temperature for 5 hours; while keeping the flow rate of argon and hydrogen constant, raise the temperature to 1000°C for 5 minutes, inject 5 sccm of methane, and grow for 15 minutes;

[0033] (3) After the growth is completed, close the feed of methane and hydrogen, keep the feed of argon continuously, remove the heating furnace body, quickly cool down to room temper...

Embodiment 2

[0036] (1) Put 2×2cm copper foil into acetone, ethanol, and deionized water for 10 minutes for ultrasonic cleaning respectively to remove oil and other organic impurities on the surface of the copper foil, then dry it with high-pressure gas and place it in a quartz crucible;

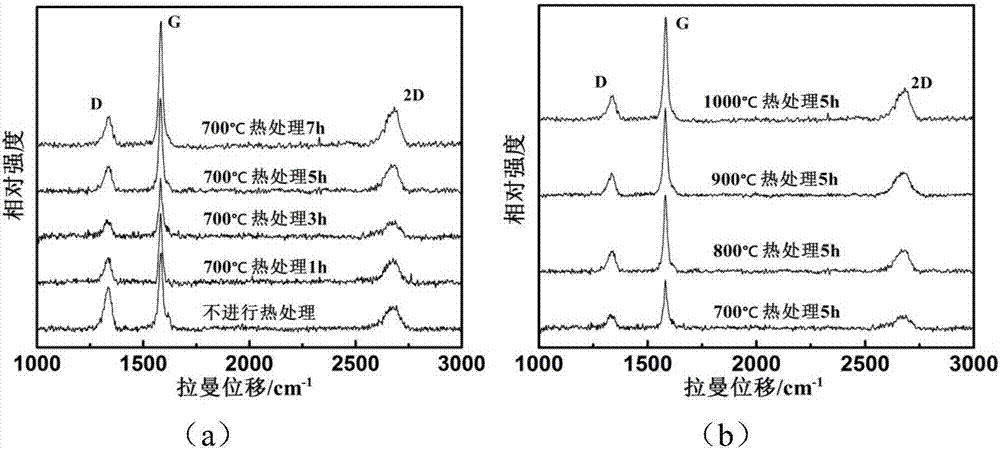

[0037] (2) Put the quartz crucible with copper foil into the constant temperature zone of the tube furnace, then evacuate the quartz tube, feed Ar gas to maintain the normal pressure in the tube; feed 300 sccm argon, 40 sccm hydrogen, and heat from room temperature for 30 minutes to 700°C, and then heat-treat the copper foil substrate at this temperature for 1 hour, 3 hours, and 7 hours; while keeping the flow rate of argon and hydrogen constant, raise the temperature to 1000°C in 5 minutes, and inject 5 sccm of methane to carry out 15min growth;

[0038] (3) After the growth is completed, turn off the introduction of methane and hydrogen, keep the continuous introduction of argon, remove the heating fur...

Embodiment 3

[0041] (1) Put 2×2cm copper foil into acetone, ethanol, and deionized water for 10 minutes for ultrasonic cleaning respectively to remove oil and other organic impurities on the surface of the copper foil, then dry it with high-pressure gas and place it in a quartz crucible;

[0042] (2) Put the quartz crucible with copper foil into the constant temperature zone of the tube furnace, then evacuate the quartz tube, feed Ar gas to maintain the normal pressure in the tube; feed 300 sccm argon, 40 sccm hydrogen, and heat from room temperature through 40 min to 1000°C, 900°C, and 800°C, and then heat-treat the copper foil substrate at this temperature for 5 hours; while keeping the flow rate of argon and hydrogen constant, raise the temperature to 1000°C, and feed 5 sccm of methane to carry out 15min growth;

[0043] (3) After the growth is completed, turn off the introduction of methane and hydrogen, keep the continuous introduction of argon, remove the heating furnace body, quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com