A near-infrared luminescent heavy metal oxide glass material with ultra-wide processing temperature range

A technology of heavy metal oxides and glass materials, which is applied in the fields of high thermal stability, high density, radiation-resistant gallium oxide-based glass materials, near-infrared luminescent glass materials, and high transmittance, and can solve the problem of difficult-to-prepare glass-forming capabilities, etc. problem, to achieve the effect of novel preparation method, high density and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In the preparation process of the above-mentioned luminescent glass, by using the air suspension containerless technology, the pollution of foreign impurities can be avoided to the greatest extent, the nucleation of heterogeneity can be suppressed, and the melt can be deeply supercooled to achieve rapid solidification. Therefore, heavy metal-based luminescent glasses with uniform composition, high purity, less impurities, and dense structure that cannot be obtained by traditional container methods can be prepared.

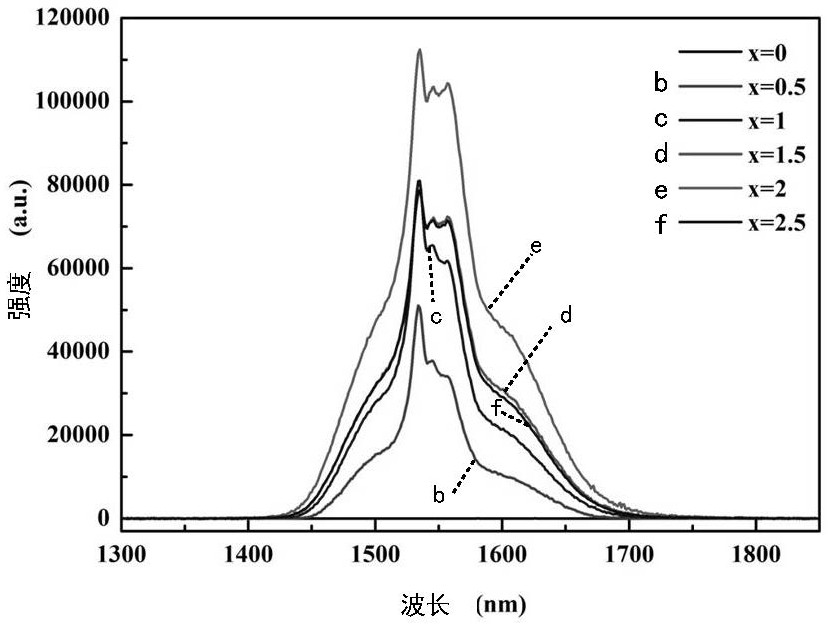

[0041] In summary, the heavy metal oxide glass of the present invention not only has high thermal stability, high transmittance, high density, and radiation resistance, but also has excellent performance of high-efficiency near-infrared luminescence (realizing efficient near-infrared output), It is expected to have potential application prospects in the fields of optical fiber communication, infrared detection, three-dimensional display and solid laser.

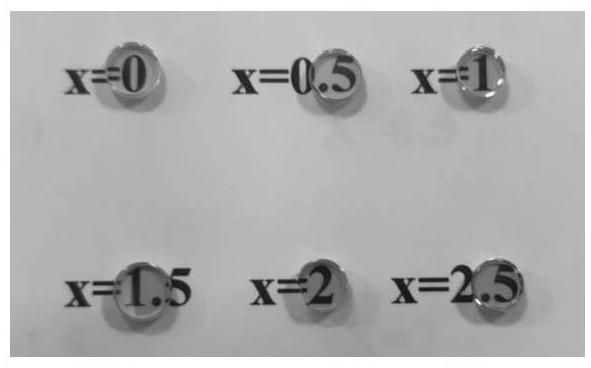

Embodiment

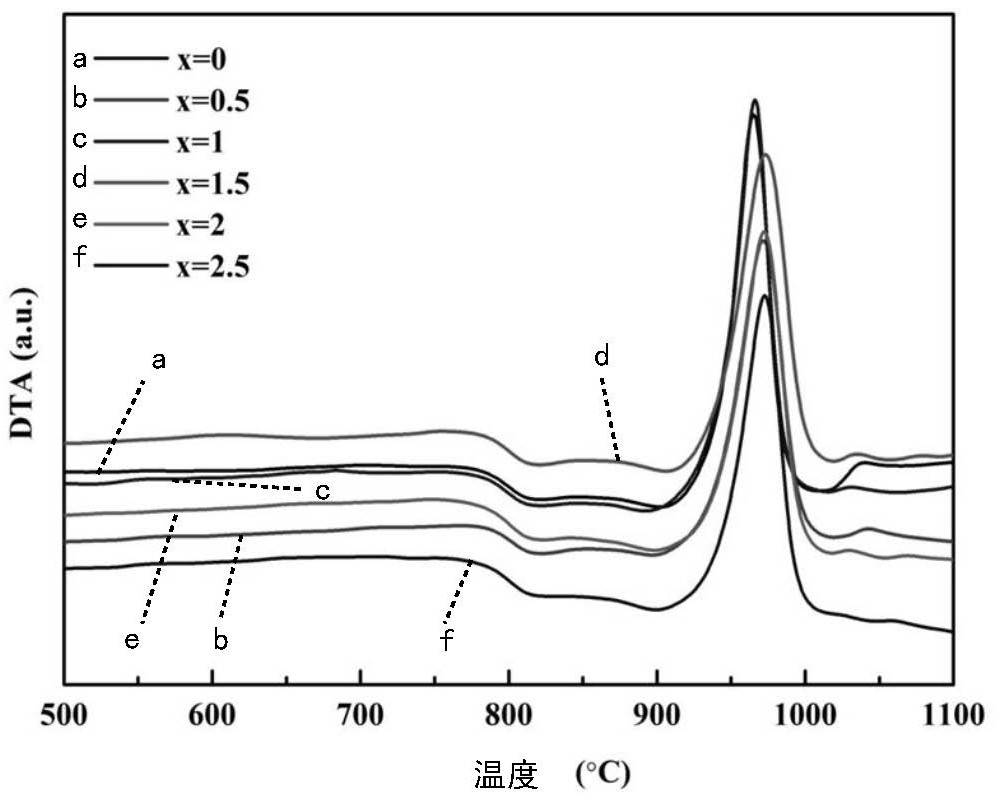

[0045] According to the ingredient formula (35-x)La 2 o 3 -55Ga 2 o 3 -10Ta 2 o 5 -xEr 2 o 3 Weigh the corresponding oxides, mix them, and wet grind them twice with alcohol, then pre-fire the mixed powder at 1250 ° C for 11 hours, the atmosphere is air, cool with the furnace, and then press it into a cylindrical shape at a pressure of about 8.5 MPa, and then Sinter at 1250°C for 12h. Take about 200mg of raw material and place it in the nozzle of the laser suspension furnace. There is no container to solidify, the atmosphere is oxygen, and the laser power is about 75W. After the sample is completely melted and uniform, turn off the laser to obtain an ellipsoidal or spherical glass without bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com