Method for efficiently producing biodiesel from kitchen grease

A biodiesel and oil technology, applied in the fields of biofuel, fat production, fat oil/fat refining, etc., can solve problems such as side reactions and affect product quality, and achieve the effects of less side reactions, greater popularization and application value, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

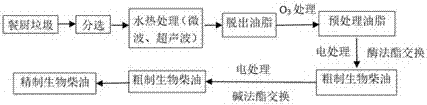

Method used

Image

Examples

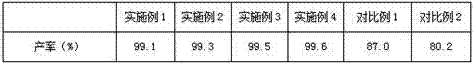

Embodiment 1

[0033] A method for efficiently producing biodiesel from kitchen fats and oils, said method comprising the steps of:

[0034] S1. Collect and remove impurities: collect food waste and remove debris such as plastic, metal and glass.

[0035] S2. Pretreatment: The food waste is subjected to hydrothermal treatment at a treatment temperature of 90°C and a treatment time of 100 minutes.

[0036] S3. Three-phase separation: Three-phase separation of the upper layer of grease, middle water, and lower layer of solid food waste of the pretreated food waste.

[0037] S4. Grease pretreatment: the separated grease is pretreated with 30g / L of ozone.

[0038] S5. Preparation of biodiesel from oil: 100g of oil separated from lipase (enzyme activity: 1000U / g, from Aspergillus niger Aspergillus niger , suitable for one-stage or multi-stage reaction), under the action of transesterification reaction with methanol to prepare biodiesel, the reaction temperature is 30°C, and the reaction is 22 ...

Embodiment 2

[0041] A method for efficiently producing biodiesel from kitchen fats and oils, said method comprising the steps of:

[0042] S1. Collect and remove impurities: collect food waste and remove debris such as plastic, metal and glass.

[0043] S2. Pretreatment: The food waste is subjected to hydrothermal treatment at a treatment temperature of 90°C and a treatment time of 100 minutes.

[0044] S3. Three-phase separation: Three-phase separation of the upper layer of grease, middle water, and lower layer of solid food waste of the pretreated food waste.

[0045] S4. Grease pretreatment: the separated grease is pretreated with 30g / L of ozone.

[0046] S5. Preparation of biodiesel from oil: 100g of oil separated from lipase (enzyme activity is 1000U / g, from Aspergillus niger Aspergillus niger , suitable for one-stage or multi-stage reactions), biodiesel was prepared by transesterification with methanol at a reaction temperature of 30°C for 22 hours; at the same time, an electric f...

Embodiment 3

[0049] A method for efficiently producing biodiesel from kitchen fats and oils, said method comprising the steps of:

[0050] S1. Collect and remove impurities: collect food waste and remove debris such as plastic, metal and glass.

[0051] S2. Pretreatment: The food waste is subjected to three-step hydrothermal treatment, that is, treatment at 120°C for 100 minutes; then, the temperature is raised to 300°C for 3 minutes; finally, the temperature is lowered to 90°C for 30 minutes.

[0052] S3. Three-phase separation: The pretreated food waste is sprayed into the three-phase separator, and the upper layer of grease, middle water, and lower layer of solid food waste are subjected to three-phase separation.

[0053] S4. Grease pretreatment: the separated grease is pretreated with 5g / L of ozone.

[0054] S5. Preparation of biodiesel from oil: the oil after ozone pretreatment is used in catalyst lipase (enzyme activity is 50000U / g, from Candida Candida mycoderma , suitable for one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com