Manufacturing method of high-strength heat-resistant organic glass fruit tray

A technology of plexiglass and a manufacturing method, which is applied in the field of glassware manufacturing, can solve the problems affecting the service life of plexiglass, low transparency, low elastic wear resistance, and rough plexiglass, and achieves improved heat resistance, strength and transparency. , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

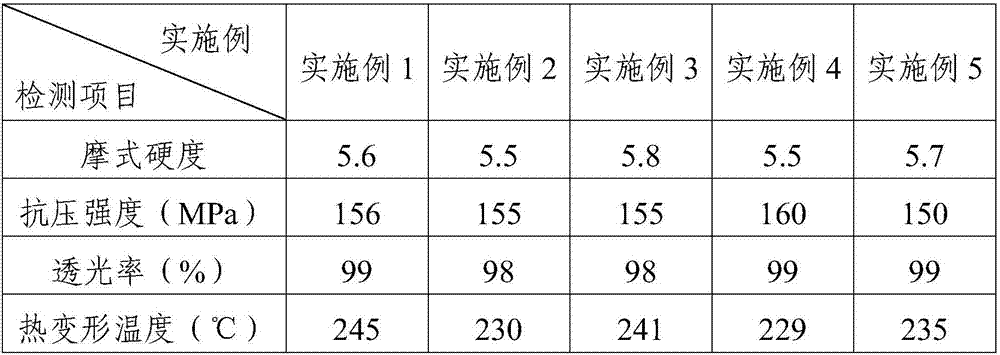

Examples

Embodiment 1

[0026] A method for making a high-strength heat-resistant plexiglass fruit plate, comprising the following steps:

[0027] (1) Weigh raw materials: Weigh 750 parts of methyl methacrylate, 150 parts of polycyclic norbornyl methacrylate, 150 parts of N-substituted maleimide, 150 parts of methacrylamide, dimethyl 55 parts of ethylene glycol acrylate, 40 parts of propylene methacrylate, 45 parts of barium methacrylate, 40 parts of montmorillonite, 15 parts of dibutyl phthalate and 8 parts of azobisisobutylcyanide use;

[0028] (2) Pre-polymerization: Add methyl methacrylate into the heating kettle, control the stirring speed to 105r / min and raise the temperature to 50°C and keep it warm, then add polycyclic norbornyl methacrylate, N-substituted maleic acid imide, methacrylamide, ethylene glycol dimethacrylate, propylene methacrylate and dibutyl phthalate, after stirring for 25min, barium methacrylate, montmorillonite and azo Diisobutylcyanide is mixed evenly and divided into 8 p...

Embodiment 2

[0031] A method for making a high-strength heat-resistant plexiglass fruit plate, comprising the following steps:

[0032] (1) Weigh raw materials: Weigh 700 parts of methyl methacrylate, 100 parts of polycyclic norbornyl methacrylate, 100 parts of N-substituted maleimide, 100 parts of methacrylamide, dimethyl 40 parts of ethylene glycol acrylate, 30 parts of propylene methacrylate, 30 parts of barium methacrylate, 30 parts of montmorillonite, 10 parts of dibutyl phthalate and 5 parts of azobisisobutylcyanide use;

[0033] (2) Pre-polymerization: Add methyl methacrylate into the heating kettle, control the stirring speed to 100r / min and raise the temperature to 45°C and keep it warm, then add polycyclic norbornyl methacrylate, N-substituted maleic acid Imide, methacrylamide, ethylene glycol dimethacrylate, propylene methacrylate and dibutyl phthalate, after stirring for 20 minutes, barium methacrylate, montmorillonite and azo Diisobutylcyanide is mixed evenly and divided int...

Embodiment 3

[0036] A method for making a high-strength heat-resistant plexiglass fruit plate, comprising the following steps:

[0037] (1) Weigh raw materials: Weigh 800 parts of methyl methacrylate, 200 parts of polycyclic norbornyl methacrylate, 200 parts of N-substituted maleimide, 200 parts of methacrylamide, dimethyl 60 parts of ethylene glycol acrylate, 50 parts of propylene methacrylate, 50 parts of barium methacrylate, 50 parts of montmorillonite, 20 parts of dibutyl phthalate and 10 parts of azobisisobutylcyanide use;

[0038] (2) Pre-polymerization: Add methyl methacrylate into the heating kettle, control the stirring speed to 120r / min and raise the temperature to 60°C and keep it warm, then add polycyclic norbornyl methacrylate, N-substituted maleic acid imide, methacrylamide, ethylene glycol dimethacrylate, propylene methacrylate and dibutyl phthalate, after stirring for 30 minutes, barium methacrylate, montmorillonite and azo Diisobutylcyanide is mixed evenly and divided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com