Self-catalysis denitration system for sintering smoke

A self-catalysis and denitrification technology, which is applied in the field of flue gas denitrification system in the field of environmental protection, can solve the problems of SCR denitrification system, such as complicated process, high investment and operating costs, and high temperature of hot ore return, so as to reduce the investment of denitrification equipment and reduce the cost of denitrification , Improve the effect of denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

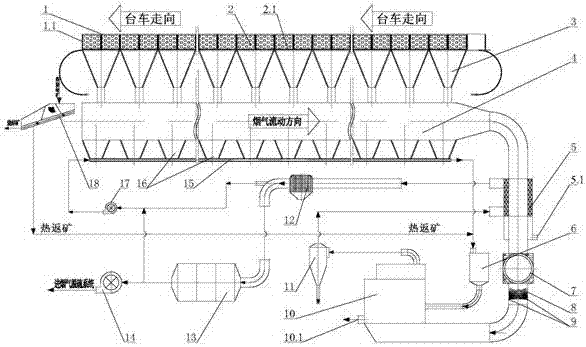

[0028] The system of the present invention will be further explained below in conjunction with the accompanying drawings:

[0029] The system includes a sintering machine 1, a bellows 3 is arranged under the trolley 1.1 of the sintering machine 1, and the outlet at the bottom of the bellows 3 is connected to the main flue 4, which passes through the shell side or the pipe of the flue gas heat exchanger 5. The process, the flue gas heater 7 and the fluidized bed denitration reactor 10 are connected, and the flue gas outlet of the fluidized bed denitration reactor 10 passes through the denitration flue gas dust collector 11 and the tube or shell side of the flue gas heat exchanger 5. , the waste heat boiler 12, the electrostatic / bag filter 13 and the high-pressure fan 14 are connected; the bottom of the flue gas heat exchanger 5 is also provided with a heat exchanger dust outlet 5.1

[0030] The tail of the sintering machine is provided with a single-roller crusher (not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com