Hydrothermal preparation method of porous silicon material and preparation method of gas fluorescence sensor

A porous silicon and hydrothermal technology, which is applied in the growth of polycrystalline materials, analytical materials, fluorescence/phosphorescence, etc., can solve the problems of porous silicon being easily destroyed, insufficient luminous intensity, and silicon wafers being easily destroyed, and achieve good adsorption , high sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

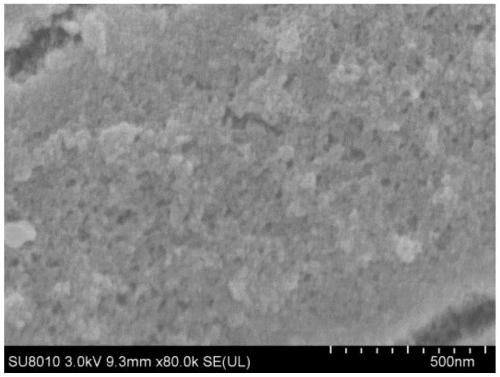

[0028] A hydrothermal preparation method of a porous silicon material, the preparation steps are as follows:

[0029] The monocrystalline silicon wafer is cleaned after soaking in ethanol and acetone; in this embodiment, the single crystal silicon wafer is a single-side polished P-type single crystal silicon wafer of 0.001-2Ω cm, and the cleaning method is ultrasonic cleaning for 10 minutes. Then rinse with distilled water repeatedly 3-5 times.

[0030] After cleaning, place the monocrystalline silicon wafer in the inner lining of the hydrothermal reaction kettle, and inject the corrosion solution into the inner lining; in this embodiment, 30-50ml of HF solution with a mass fraction of 40%, and a concentration of 0.3-1mol / L 5-20ml of zinc nitrate corrosion solution.

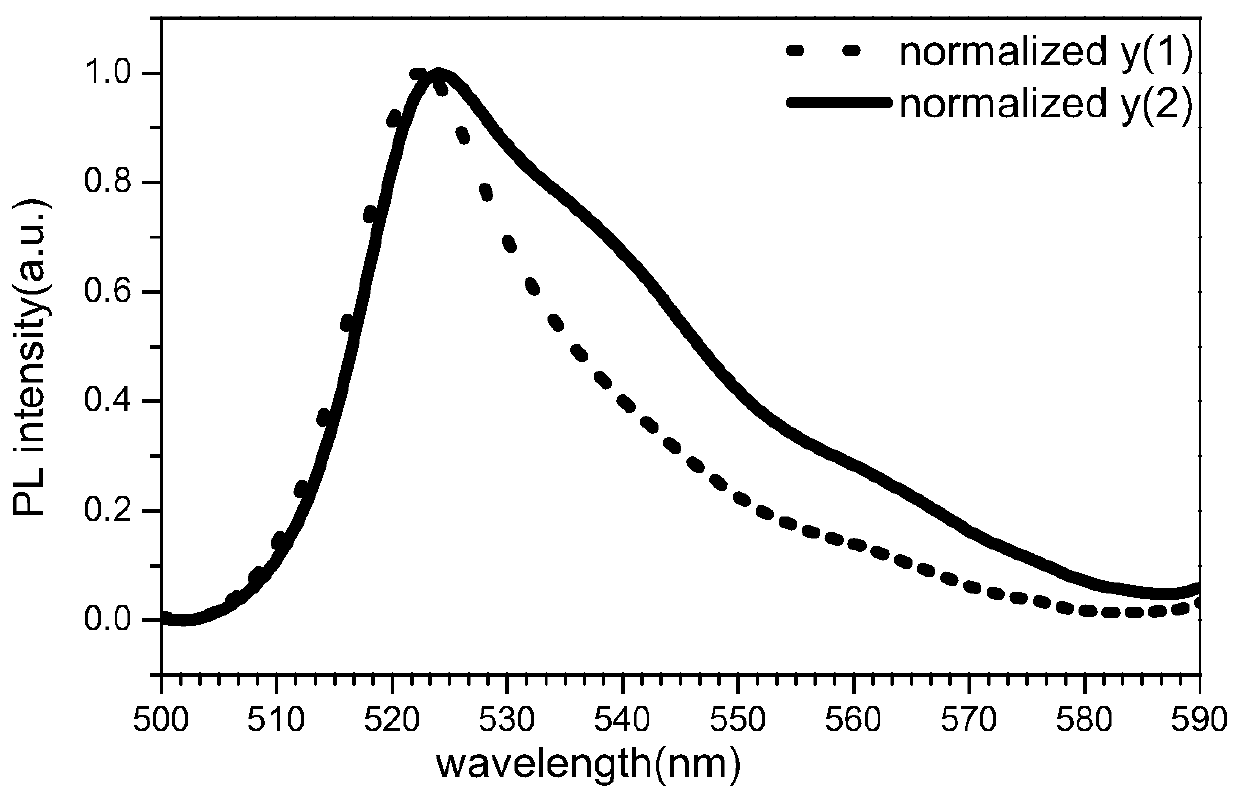

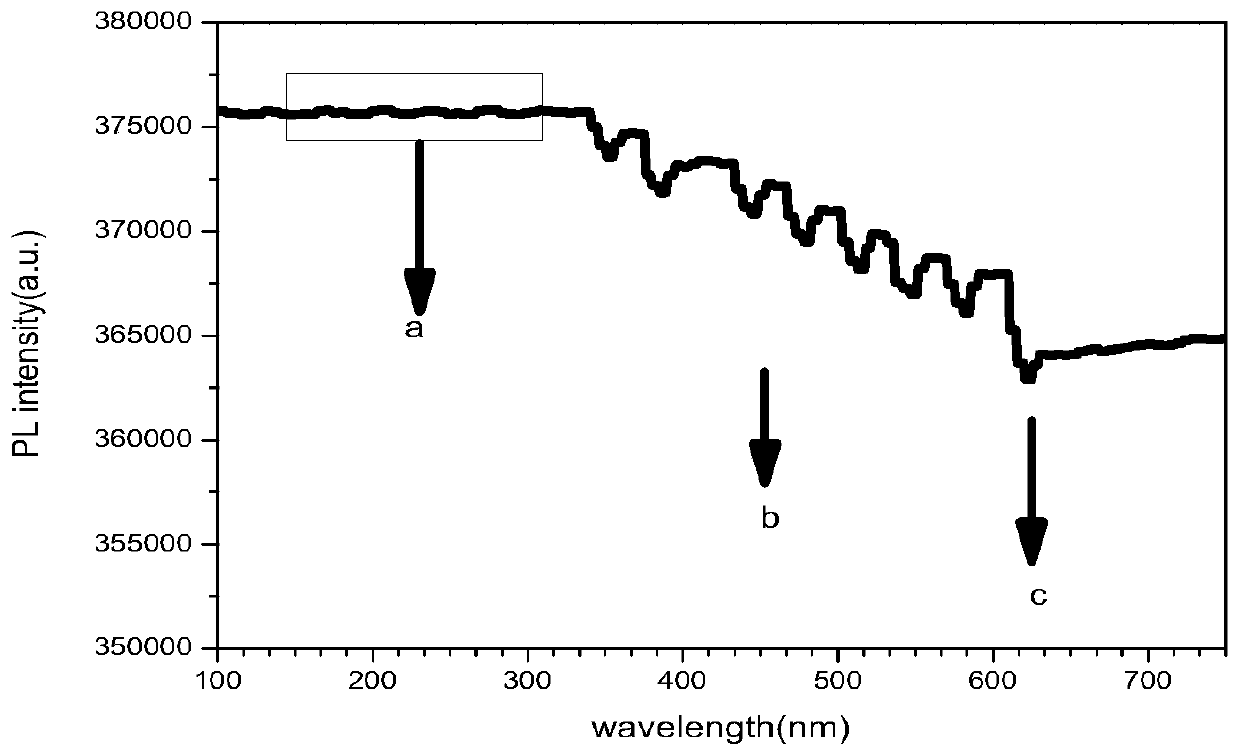

[0031] Put the inner liner in the shell of the hydrothermal reactor, cover and tighten it, put the hydrothermal reactor in an oven for heating reaction, the temperature is 140°C, and the time is 1-2 hours, afte...

Embodiment 2

[0036]Basically the same as Example 1, the difference is that the corrosion solution injected into the lining of the hydrothermal reaction kettle is 50ml of HF solution with a mass fraction of 30%, and 20ml of zinc nitrate with a concentration of 0.3mol / L; The temperature is 160°C, and the time is 1 hour; take out the monocrystalline silicon wafer and rinse it clean, soak it in 3% hydrogen peroxide for 2 days after washing, take it out and dry it; the polymer fluorescent material is poly[2-methoxy base-5-(3',7'-dimethyloctyloxy)-1,4-phenylethyn].

[0037] The technical effect of this embodiment is basically the same as that of Embodiment 1.

Embodiment 3

[0039] Basically the same as Example 1, the difference is that the corrosion solution injected into the lining of the hydrothermal reaction kettle is 60ml of HF solution with a mass fraction of 30%, and 10ml of zinc nitrate with a concentration of 1mol / L; The temperature is 130°C, and the time is 2 hours; after the reaction is completed and cooled to room temperature, the single crystal silicon wafer is taken out and rinsed. Poly[2,5-bis(3',7'-dimethyloctyloxy)-1,4-phenylenevinylene].

[0040] The technical effect of this embodiment is basically the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com